Search

Search

Search

Search

Integrated reservoir evaluation approach combines MRIL® service and RDT™ testing service

Download PDFMature Fields

Increase production and locate new zones once considered uneconomical

Offshore Gabon, West Coast of Central Africa

Offshore Gabon Upper Cretaceous formations are complex and prolific reservoirs. Completion strategies benefited from robust formation evaluation techniques from LWD and wireline sensor integration. Halliburton worked closely with Perenco to develop an integrated measurement and analysis workflow that resulted in large perforation campaigns with substantial gains in production, as well as the development of new hydrocarbon zones that were previously deemed uneconomical.

Some offshore Gabon hydrocarbon reservoirs containing oil, gas, and condensate were previously considered uneconomical. Many of the reservoirs are thin stacked, and each may have its own oil/water contact. The lithology can be complex and consists of interbedded sandstones, limestones, dolomites, and claystones. The amount of feldspars and mica affect basic interpretations, and low-resistivity contrast pay zones are common due to the presence of interbedded sand/shales. Clay volume, water saturation, and reservoir quality are highly variable and unpredictable based solely on conventional log interpretation.

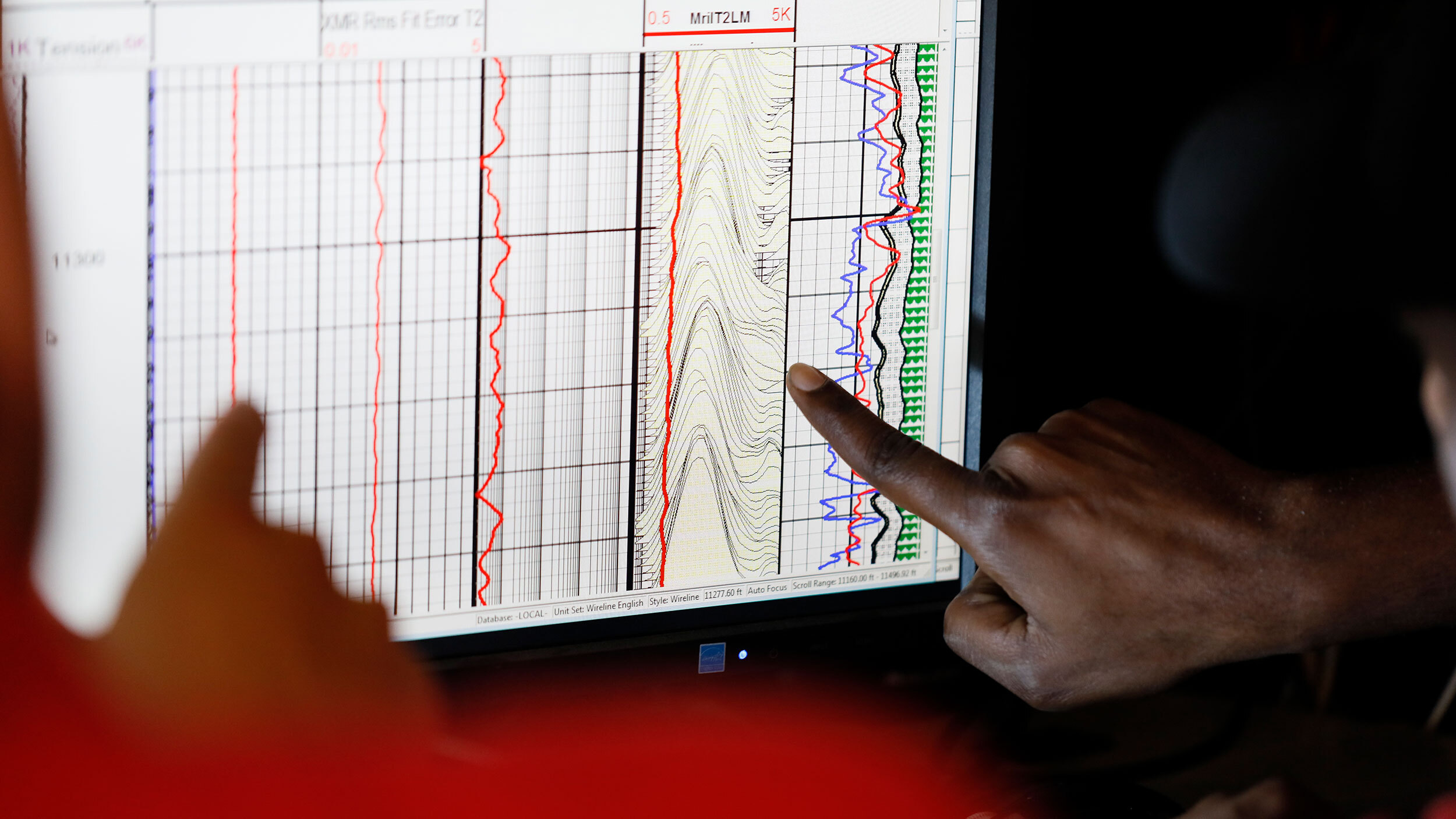

Halliburton and Perenco collaborated on an integrated workflow combining conventional logs, nuclear magnetic resonance (NMR) from the Magnetic Resonance Imaging Logging (MRIL®) tool, and pressure testing, sampling, and fluid analysis from Reservoir Description Tool (RDT™) technology. Irreducible water saturations from NMR were compared against total water saturations, as well as total porosity and permeability estimations to optimize formation pressure test depth selection. MRIL direct fluid typing was also used to optimize the fluid pumpout sampling stations, and sampling results favorably confirmed fluid predictions. If mobility was high enough to move formation fluids, a pumpout operation was performed to confirm the reservoir fluid type and to monitor and minimize the degree of filtrate contamination before PVT sample collection.

BOPD for an existing well

BOPD for a new well

A precise reevaluation of several reservoirs with MRIL and RDT pumpout wireline formation tester technologies on new wells resulted in large perforation campaigns with substantial gains in production: 1,000 BOPD on an existing well on the west flank of the field and more than 4,000 BOPD on another newly drilled well.

More than 100 meters of conventional whole core was cut in a field that produced for more than 15 years. Core analysis with a focus on sedimentology provided valuable reservoir architecture information. The MRIL service information was very complementary in this reservoir environment because it is mineralogy-independent and focuses on reservoir fluids. NMR provided reliable capillary and clay-bound water volumes for determining whether or not formations were at irreducible water saturation or if they would produce mobile water.

RDT pressure testing and fluid sampling were used to pump reservoir fluids from the formation into the tool to confirm mobility and to reliably confirm reservoir fluid type, reservoir compartmentalization, and oil/water contacts.

Sensor integration and collaborative formation evaluation and interpretation provided key information towards redesigning well completion strategies and increasing production from existing reservoir plays and for developing new hydrocarbon zones previously considered uneconomical.

The nuclear magnetic resonance measurements provided by the range of MRIL®-WD™ services enable early identification of critical petrophysical parameters.

Examine the smallest pores and characterize formations using high-resolution, best-in-class magnetic resonance logging.

Reservoir Xaminer™ grants high-quality formation evaluation data in real-time for improved data quality, optimized rig time, and a higher asset value.