Search

Search

Search

Search

Cut and recovered 180 ft. of 4 in. core in three concurrent 60 ft. runs using a single core head

Download PDFMature Fields

Reduce costs during a conventional coring project in the Thebes formation

Eastern Desert

An operator needed to reduce costs during a conventional coring project in a mature field in the Thebes formation located in the Eastern Desert region and requested Halliburton’s services.

The Thebes formation is well known for damaging chert that reaches +30% in some regions. With complete losses experienced previously near the top of the formation, the challenge was to cut and recover 180 ft. of core and efficiently use core heads, which helps reduce costs.

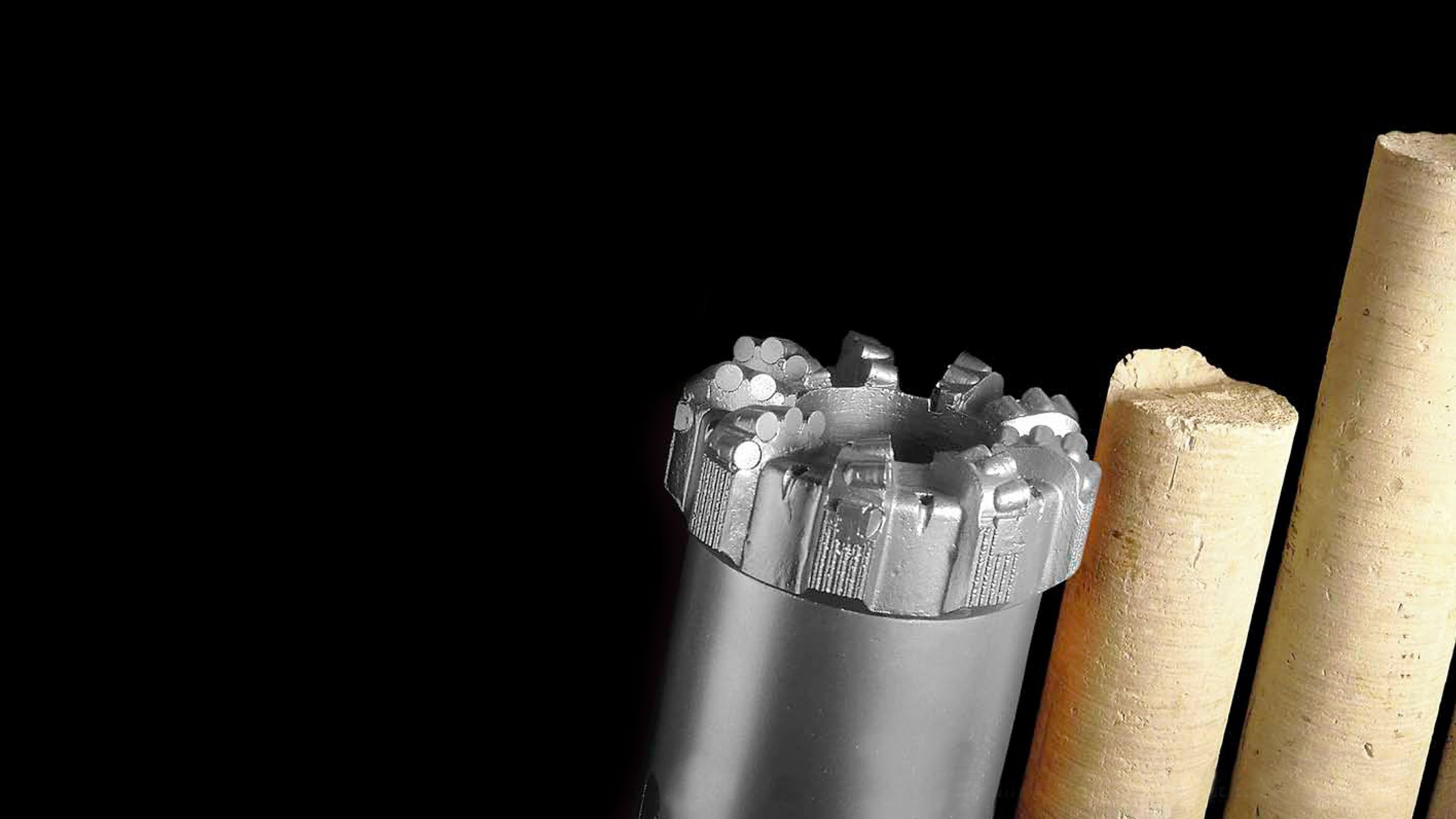

Halliburton selected 6-3/4 × 4-in. conventional coring with an adjustable safety joint. Using the latest thermally stable cutter technology, Halliburton optimized an 8-1/2-in. FC3943 core head design to maintain good performance and efficiency and ensure the extra durability necessary in cherty limestone.

The team carefully applied optimum parameters throughout the operation to maximize core efficiency and performance. In previous wells, the operator set the 9-5/8 in. casing point at 1,000 ft., which resulted in a longer open hole and additional exposure to losses in these zones. To reduce potential losses and increase coring success in this well, the casing point was set at the top of the Nukhul formation, which reduced the open hole length to 700 ft. Additionally, mud weight was reduced from 10.2 to 8.8 lbm/gal.

Feet of 4-in. core recovered

Savings

The 8-1/2 × 4-in. FC3943 core head design helped successfully cut and recover 180 ft. of 4-in. core in three concurrent 60 ft. runs using a single core head. The core head was in excellent dull condition upon completion of the operation. Because multiple core heads were unnecessary, the operator saved approximately 40K USD.

Coring systems that maximize recovery of high-quality core samples in the most extreme environments.