Search

Search

Search

Search

Innovative coring technology overcomes difficult salt formations, achieves unprecedented 300-foot oriented coring run

Download PDFUnconventionals

Collect data on caprock and salt lithology to evaluate first underground storage

Oriented coring

An operator explored the possibility of gathering extensive lithological information on the caprock and salt lithology that would be used as a salt cavern for the first underground oil storage in the UAE. Halliburton was challenged to leverage its worldwide and in-country expertise to offer solutions and technology to tackle the challenging conditions and achieve success. The challenges included the absence of lithological trends in offset wells drilled more than 20 years ago, the need for an exploratory unconventional well, and an unstable formation with alternating lithology unconformity. Additionally, there was a high risk of losses, issues with well verticality, the necessity for core orientation with extended coring, and high core quality to facilitate storage and leaching effectiveness.

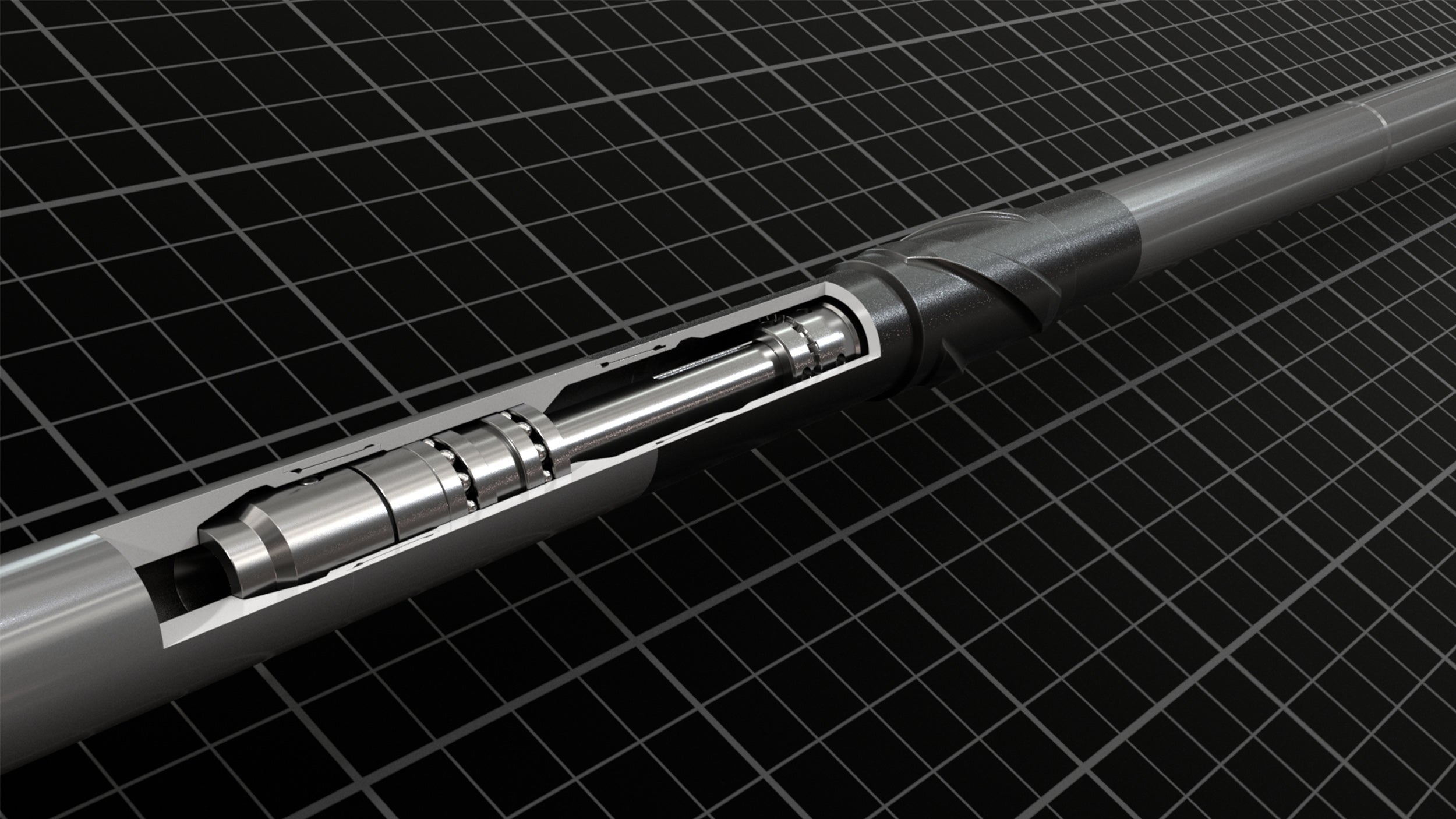

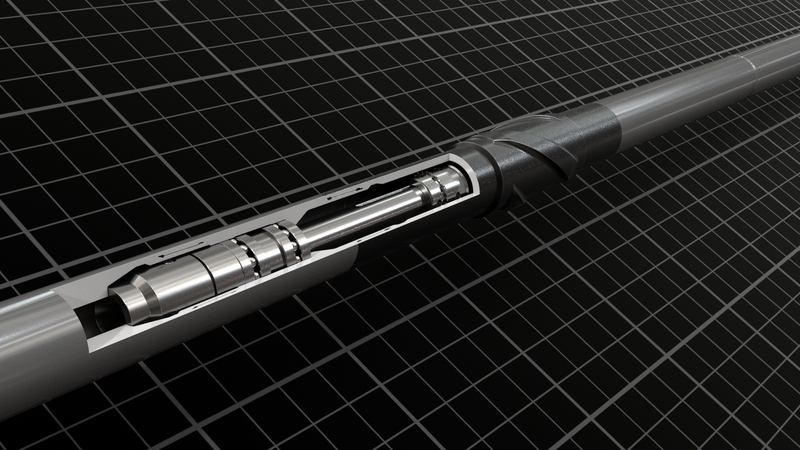

To address these challenges, the RockStrong™ coring system was introduced to overcome vibrations. The 8.5 in. FC74WRK core head, designed with the latest Machete™ 4D-shaped cutter technology, was utilized. Extensive BHA planning, modeling, and coring roadmaps were developed, and a hybrid electromagnetic core orientation system was implemented. The operator and Halliburton used personnel experience and technical competency to collaborate and execute.

The 8.5 in. FC74WRK core head, along with the RockStrong coring system with anti-jamming and oriented coring technology, successfully cored more than 2,000 ft. This achievement set a new record for coring through challenging salt formations, completing a 300-foot oriented coring run in one run. This broke the previous record of a 240-foot oriented coring run.

The RockStrong™ coring and anti-jamming system was designed for maximum reliability under the harshest conditions.