Search

Search

Search

Search

Combination of GeoTap® IDS and MRIL®-WD™ LWD sensors is perfect match to reduce significant time and costs

Download PDFDeep water

Gathering formation and evaluation data while reducing deepwater rig costs

Mexico

Confirming structural geometry and distribution of producer sediments, and gathering a full range of formation and evaluation data while reducing deepwater rig costs.

A full suite of LWDsensors –including the MRIL®-WD™ and GeoTap® IDS sensors – to identify the target locations and collect the samples in real time:

Retrieved real-time FE data and preventedwireline runs that demand extra costly deepwater rig days.

An operator on a deepwater well had recently issued an internal mandate seeking opportunities to reduce the authorizations for expenditure (AFEs) associated with drilling its oil and gas exploration and development projects. In alignment with the operator’s initiative, Sperry Drilling identified that its wide range of logging-while-drilling (LWD) services could provide significant opportunities to support this cost-reduction mission while retrieving the desired formation and evaluation information ranging from gamma and density to magnetic resonance and fluid sampling in the operator’s three certified reservoirs (MM-YAC1, MM-YAC2, and MM-YAC3) in the Middle Miocene formation.

With water depths of 8,793 feet (2,680 meters) and 5,610 feet (1,710 meters) off the coast of Veracruz, the operator needed fluid samples to confirm the structural geometry and distribution of the target sedimentary facies within the production field. In the past, this operation would normally need two trips that added on costly deepwater rig time – one trip to drill the well and another trip to obtain the fluid formation samples by wireline. By drilling and logging a delimiter well, and thus establishing the vertical and horizontal lengths on the three certified reservoirs, the operator could decrease the uncertainty to classify the 154 MMBOE (865 MMSCF) of possible and probable reserves and to add 32 MMBOE (180 MMSCF) to possible reserves. To decrease this uncertainty while driving down costs, the operator turned to Sperry Drilling to provide a one-trip solution to drill and log with a full range of formation and evaluation data, and to capture formation fluid in real time.

Sperry Drilling, in collaboration with the operator, determined that the best route would be to utilize a full suite of logging-while-drilling (LWD) sensors that included the MRIL®-WD™ and GeoTap® IDS sensors. The full string of LWD sensors included:

| LWD Service | Real-Time Measurement |

|---|---|

| ALD™ Sensor | Density |

| QBAT™ Sensor | Sonic – Compressional Slowness |

| CTN™ Sensor | Neutron Porosity |

| DGR™ Sensor | Gamma |

| EWR® Sensor | Resistivity |

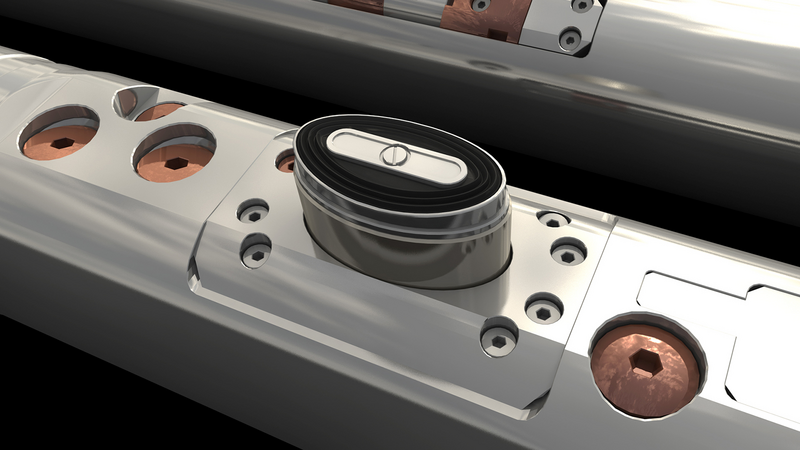

| GeoTap® IDS Sensor | Formation Pressure and Fluid Sampling |

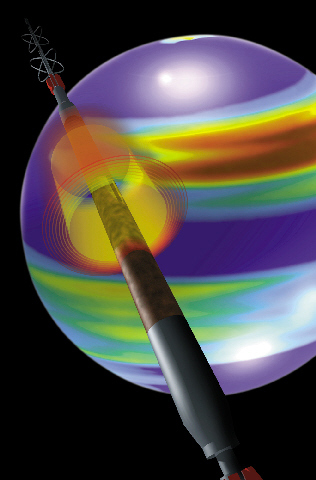

| MRIL®-WD™ Sensor | Magnetic Resonance |

The MRIL-WD sensor allowed for precise real-time formation pore size analysis along the well plan, determining the sweet spots for testing and sampling with the GeoTap® IDS sensor, which would identify and collect the fluid samples. It was important that the operator receive high-quality formation fluid samples with low contamination for further lab analysis at the surface. Sperry Drilling provided 24/7 real-time onsite support at the operator’s office, allowing for constant interaction with the rig crew. Formation and evaluation LWD logs, including the MRIL-WD magnetic resonance system, were relayed immediately to the experts for data interpretation. By providing real-time LWD data, the operator was able to expedite logging decisions, collect formation samples on the drilling run, and avoid wireline runs.

reduced deepwater rig days

total USD saved

nonproductive time (NPT

The Sperry Drilling utilized the LWD logs, along with Formation and Reservoir Solutions (FRS) and Log Quality Assurance (LQA) to assist the team in suggesting the best 12 pretest formation pressure points. The customer decided to log the section with MRIL-WD T1 activation while drilling, and then wipe upward using the MRIL-WD T2 activation.

Initially, the MRIL-WD sensor was run in the directional hole for 2,014 feet (614 meters) in 51.1 hours with an average rate of penetration (ROP) of 39 feet (12 meters) per hour. Throughout the entire run, a real-time data detection rate greater than 95 percent was achieved with the positive pulse (P4M) telemetry service, assuring high-quality data transfer even with the longest bottomhole assembly (BHA) string run in Mexico. The GeoTap® IDS service – which includes formation pressure sampling, fluid collection, and fluid identification – performed as expected, conducting 30 pretests and gathering three samples with zero nonproductive time (NPT). After more than 40 activations, the oval pad, which is critical to the formation pressure seal, was in perfect condition. The combined outstanding drilling performance, along with the deployment of LWD services that included the MRIL-WD and the GeoTap IDS sensors, resulted in savings of USD 1.1 million for the replacement of wireline services and a total of 15 days saved on overall operations, amounting to a total of USD 7.5 million.

Gather real-time, high-quality data while drilling for improved subsurface insight, increased ROP, and enhanced wellbore stability.

The nuclear magnetic resonance measurements provided by the range of MRIL®-WD™ services enable early identification of critical petrophysical parameters.

Fluid identification and sampling solution.