Search

Search

Search

Search

Advanced bit technology and strategic planning help deliver longer runs and improve ROP

Download PDFMature Fields

Drill 4,070 m of challenging formation in 12 1/4-in. section

Mexico

Zone 3 in Mexico presents significant drilling challenges due to its complex environment. An operator collaborated with Halliburton to develop a custom drill bit solution aimed at improving the rate of penetration (ROP) and achieving extended bit runs. The team applied lessons learned from offset wells and implemented a tailored bit design strategy, supported by real-time monitoring and operational decision-making.

The operator encountered complex drilling conditions, such as interbedded shale, sandstone, and conglomerates with high compressive strength made it difficult to maintain drilling efficiency. These conditions increase the likelihood of tool failure, frequent trips to the surface, limit ROP, and make it challenging to achieve longer bit runs. The challenge was further compounded by the targeted formation being 300 m thicker than in nearby wells, requiring extended drilling through repeated lithologies.

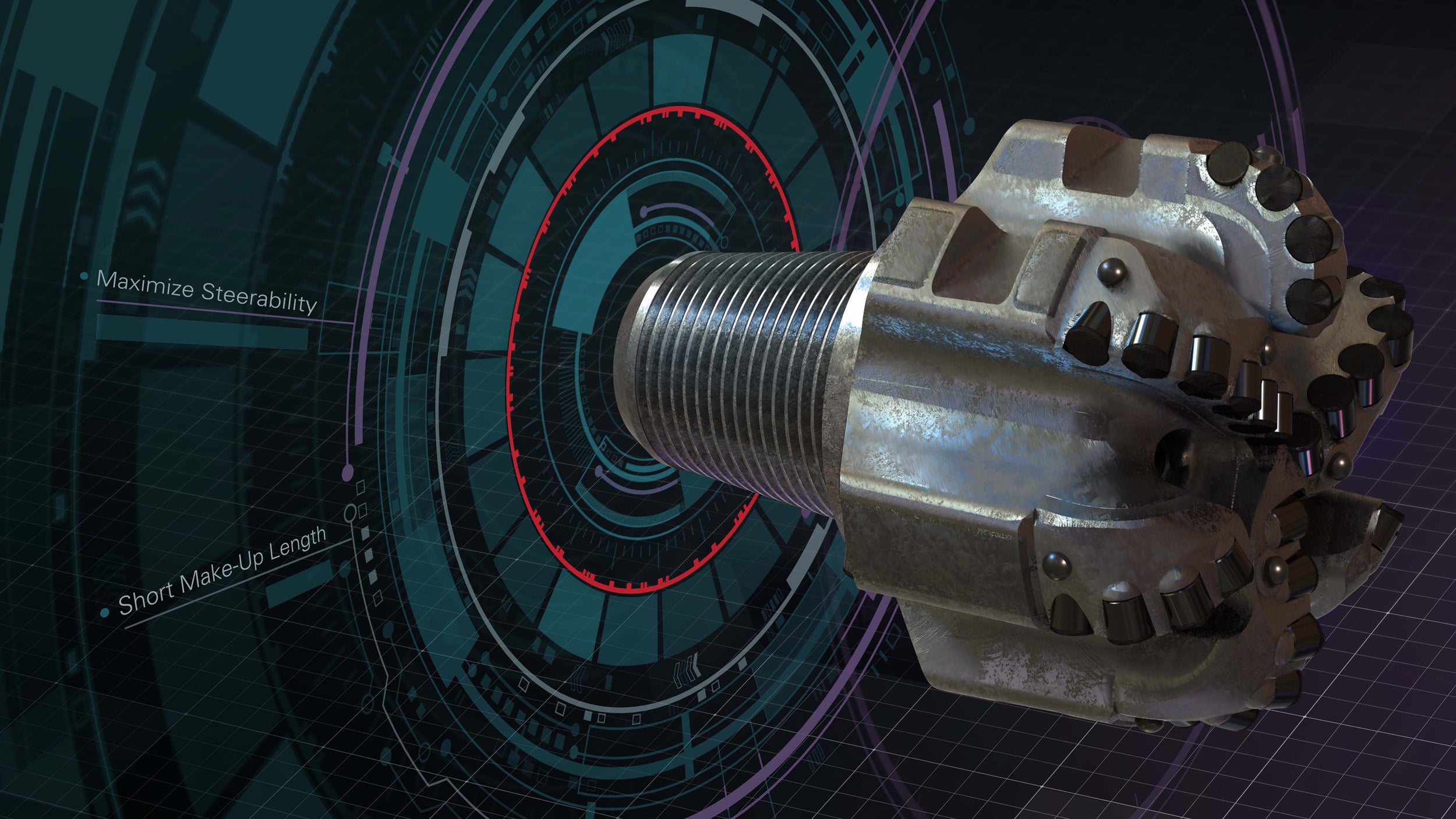

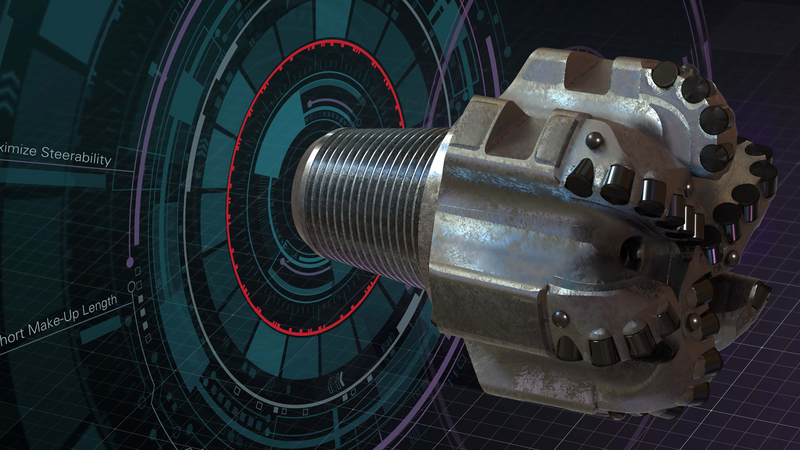

To address drilling challenges, the operator and Halliburton conducted a comprehensive review of offset wells. This analysis included formation characteristics, drilling parameters, bottom-hole assembly configurations, and bit wear patterns. The collaboration led to the development of three PDC bit designs tailored to the expected lithology variations. Key bit technologies included Hedron® fixed cutter drill bits, Hypersteer™ directional drill bits, and Juggernaut® X cutters. Design elements such as bit body type, cutter shape, and nozzle configuration were selected to optimize performance across varying rock types.

While drilling, continuous real-time monitoring and proactive decision-making played a critical role. A structured decision tree, developed through joint technical reviews and cost-benefit analysis, guided optimal bit change timing and helped avoid unnecessary trips. This integrated approach enabled consistent drilling performance and maximized bit life in the formation.

Days of drilling time saved

Meters drilled

Days faster than offset well

Increase in ROP

The collaboration enabled the operator to accelerate the well construction process, completing the 12¼-in. section 17 days faster than the best-performing offset well in the area. The operation also achieved a 46% increase in ROP compared to the original schedule and delivered longer bit runs with no structural damage, exceeding planned KPIs.

These outcomes were made possible through the successful implementation of precise drill bit designs, supported by real-time monitoring and coordinated execution. This approach established best practices for drilling in challenging environments, reduced drilling time by 10.4 days, and generated substantial savings in equipment and operational costs.

Directional drill bits designed for high build rates in curve and lateral applications.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Juggernaut X PDC cutters increase rate of penetration (ROP) and reduce well construction time. They offer superior durability and efficiency.