Search

Search

Search

Search

Protech II™ centralization helps operator mitigate differential sticking risk

Download PDFDeepwater

Reach planned total depth while running through restricted inner diameters

Egypt

It can be challenging to reach casing to the planned total depth when drilling deepwater wells with tight annular clearance sections. Conventional centralizers are limited to the restoring force available after they pass through a restricted inner diameter (ID). This can have a negative impact on equivalent circulating densities (ECDs) because of the limited available flow area in casing overlaps.

An operator designed a seven-section well with tight annular clearance for the casing run and cement operations to achieve production/construction objectives in the Mediterranean Sea. While running in hole (RIH) with casing, differential sticking of the string is a major risk that can compromise the capability to reach TD. This is particularly true when running through permeable formations and restrictive previous casing IDs.

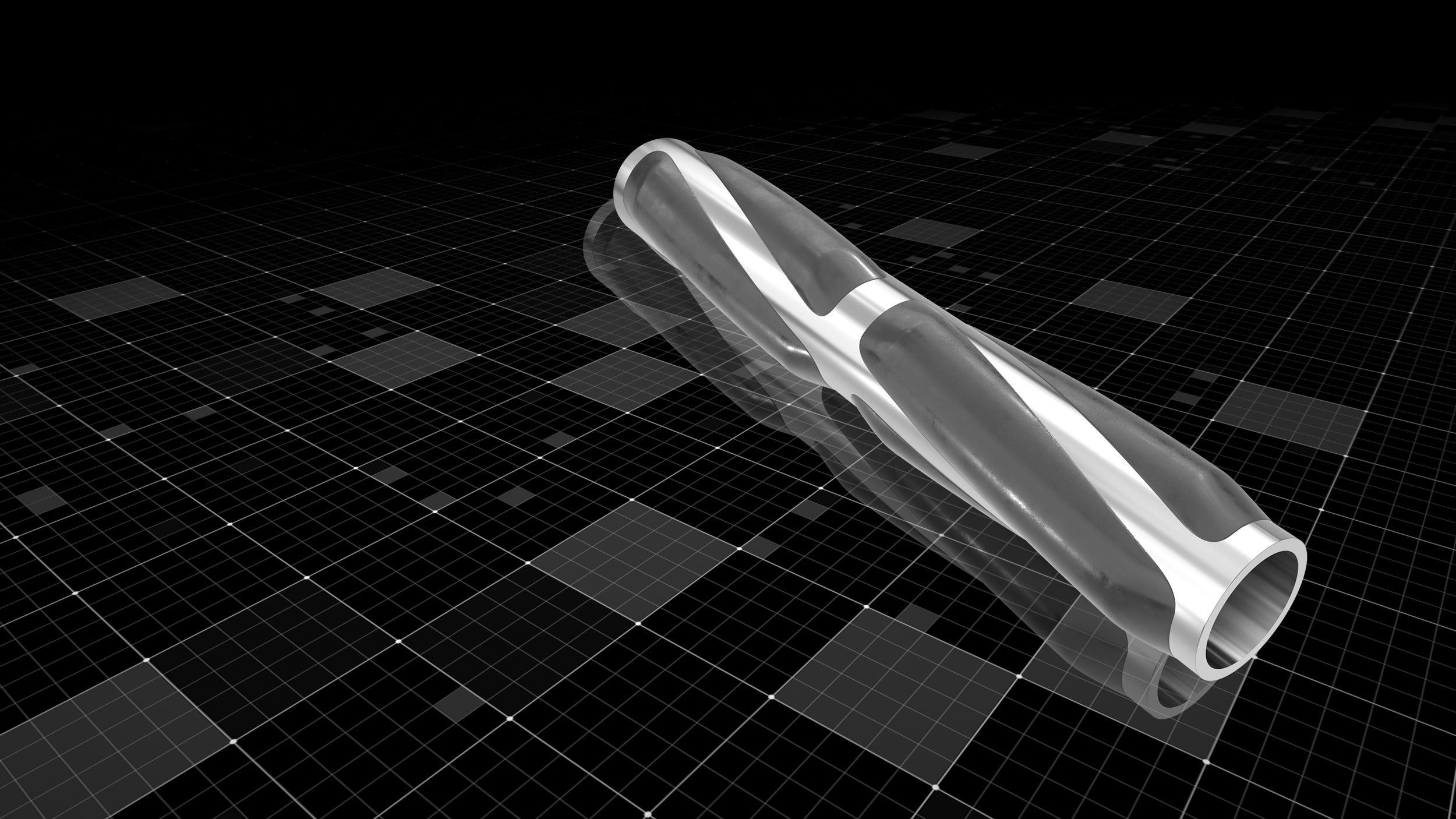

Halliburton proposed a tailored approach to casing string centralization with the Protech II™ centralizer technology in four strings in the well: the 16-, 13 5/8-,11 3/4, and 9 5/8-in. casing sections.

Protech II centralizers offer on-pipe standoff blades designed and manufactured with tailored spacing and geometry to allow safe passage through restrictive IDs. The 360° true string offset prevents casing from contact with exposed permeable formations. This minimizes the risk of differential sticking and allows unrestricted flow paths to minimize ECD during circulation and cement applications. Because frictional forces on the centralizer body caused by the wellbore can make it difficult to reach planned depth, Protech II centralizers provide ultralow friction coefficients that reduce frictional forces.

Differential sticking

Casing strings

in. radial clearance

Degree true string offset with centralizer technology

With the Protech II centralization system, the operator reached the casing landing depth and executed cement operations without differential sticking. This saved rig time that could have been spent on stuck pipe issues. It also helped achieve the desired zonal isolation – despite the tight annular clearance of 0.45 in. radially.

Protech™ II centralizers reduce friction, enhance flow area, and keep positive standoff.