Search

Search

Search

Search

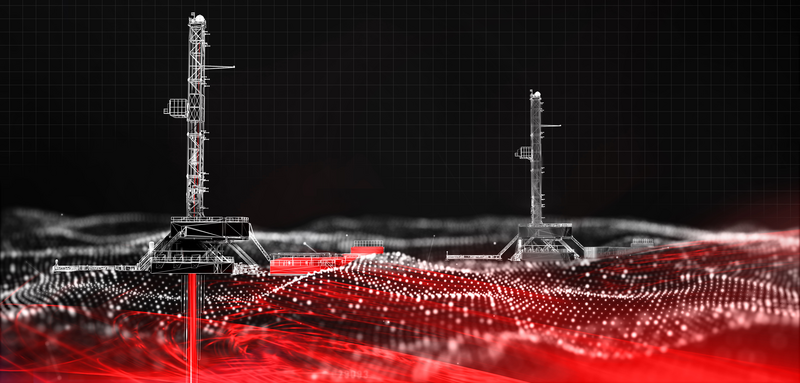

Identifying coring point with accuracy using azimuthal focused at-bit resistivity measurements

Download PDFDeep Water

Identify coring point with at-bit LWD solutions

Nigeria

The engineered technology solution included:

An operator in Nigeria uncovered a new significant oil and gas discovery in an oil mining lease (OML) located offshore eastern Niger Delta. The asset was successfully drilled from surface to well target depth (TD), with a customized suite of logging-while-drilling and measuring-while drilling (LWD/MWD) solutions that included formation testing, neutron-density, and sonic in an oil-based mud system.

The well challenges required a new strategy. The operator needed to first identify the possibility of reservoir sand and determine if the reservoir was hydrocarbon-bearing or wet. They had to precisely drill with only a 5m tolerance in the target reservoir and geostop at the right depth to maximize the coring interval.

“At-bit resistivity has proven to be a very reliable measurement in real time when quick decisions need to be made to identify the optimum coring depth and section TD.

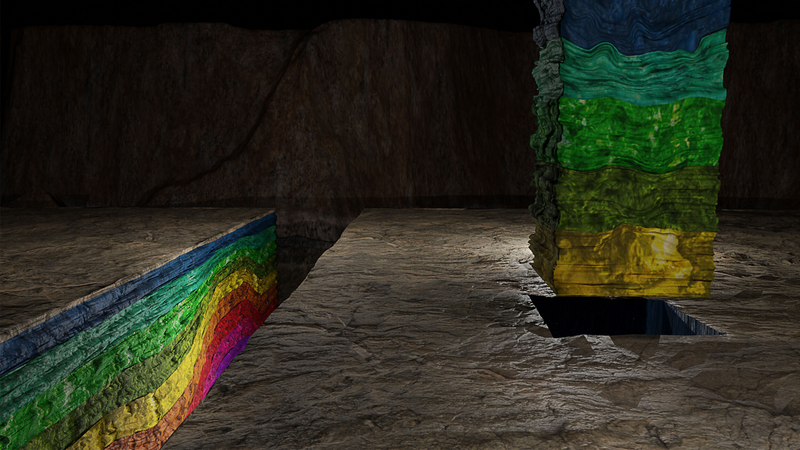

Halliburton offered a comprehensive bottomhole assembly (BHA) to help reach the well objective. The at-bit AFR azimuthal focused resistivity service was key to accurately completing the 8½-in. hole section of the well, along with data obtained from the FTWD GeoTap® formation pressure testing service and the gamma ray, sonic, and neutron/density services in an oil-base mud system.

The real-time, at-bit resistivity measurements enabled geostopping successfully 2m into the reservoir optimizing the coring interval. As a result, the operator was able to confirm the presence of hydrocarbon at the top of the target reservoir (2182m MD).

The new discovery has added to Nigeria’s cumulative oil and gas reserves, laying the foundation for future development and production investments to further grow the country’s oil and gas output.

The operator has since reported that the new discovery well encountered 38 meters of net oil pay and 15 meters of net gas pay, while its sidetrack encountered 73 meters of net oil pay, in well-developed and excellent-quality reservoirs.

This implemented solution provides valuable inputs for upcoming exploration wells, where the deepest objective rests on top of an over-pressured zone. At-bit resistivity measurements enable the client to access the presence of hydrocarbon in the reservoir by drilling only a few meters without the risk of entering the over-pressured zone.

High resolution logging-while-drilling borehole images.

Halliburton delivers superior drilling performance to reduce time to first oil, enhance reservoir knowledge, and maximize production.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations