Search

Search

Search

Search

iCruise® intelligent RSS with Geotech™ drill bit delivers outstanding results using BaraXcel™ fluid

Download PDFUnconventionals

Develop an engineered drilling solution to meet the steering objectives

Mountrail, North Dakota

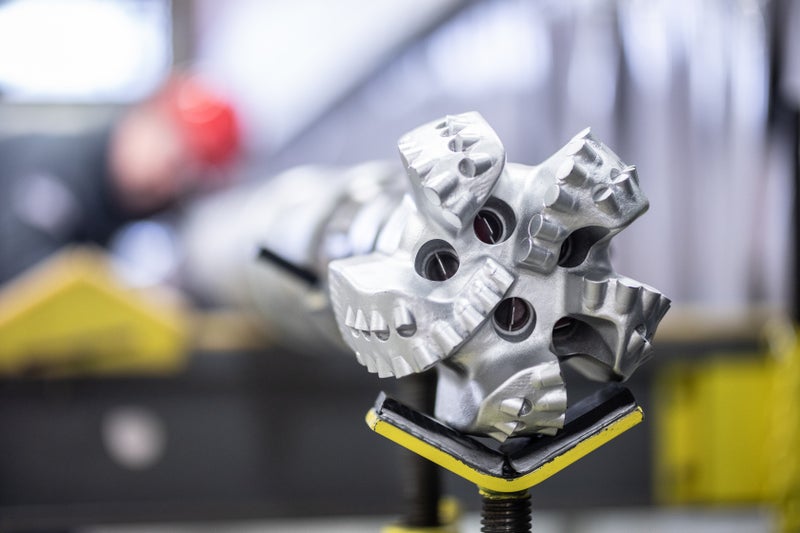

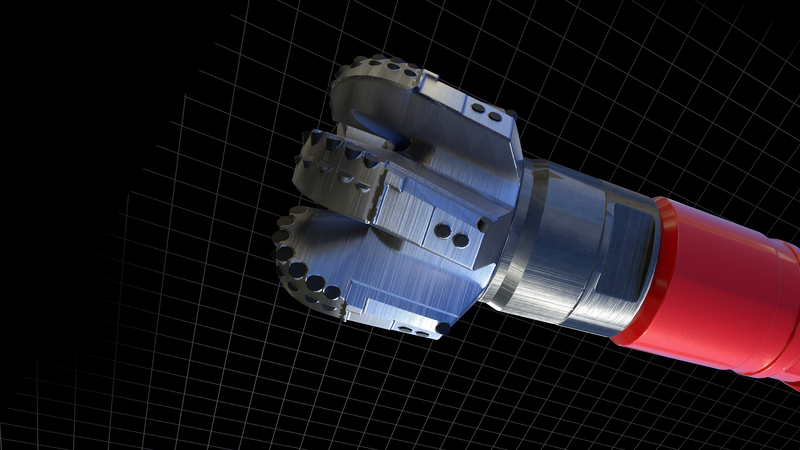

An operator in the Bakken Basin challenged Halliburton Sperry Drilling to deliver a monobore well architecture with the same AFE days as standard wells. By listening to the technical challenges and through collaboration with the operator, the Halliburton team developed an engineered drilling solution. This included the 6¾-in. iCruise® intelligent rotary steerable system (RSS), matched with an 8½-in. GeoTech® GTi54WMO drill bit, powered by a 7-in. NitroForce® high flow, high torque motor, and the BaraXcel™ high-performance, non-aqueous fluid system. The equilibrium, force, and critical speed modules of DrillingXpert™ well engineering software were used to model the bottomhole assembly (BHA) design to meet the steering objectives, while balancing side forces across the BHA and identifying the optimum operating window to minimize vibration.

Days Ahead of AFE

Increase in ROP

Average DLS (⁰/100’)

The solution helped the operator maximize asset value by delivering the lateral section 0.28 days ahead of AFE, with an average dogleg severity (DLS) of 0.62°/100, and a 3.5% increase in ROP, while keeping surface torque under 26k ft/lb. Additionally, the monobore well design was proven to be effective for this type of application, identifying future savings and reliability in the completion arena, further optimizing customer assets.

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

Specialized drill-in fluids for every reservoir that improve well productivity and reduce formation damage.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

Provides the power and performance to consistently deliver faster and longer runs.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.