Search

Search

Search

Search

BaraShield®-981 and BAROFIBRE O composite LCM help reduce downhole losses to the formation by quickly sealing fractures across fault zone

Download PDF

QATAR

Drill an extended horizontal section in a depleted offshore reservoir

BaraShield®-981 and BAROFIBRE O composite LCM engineered to:

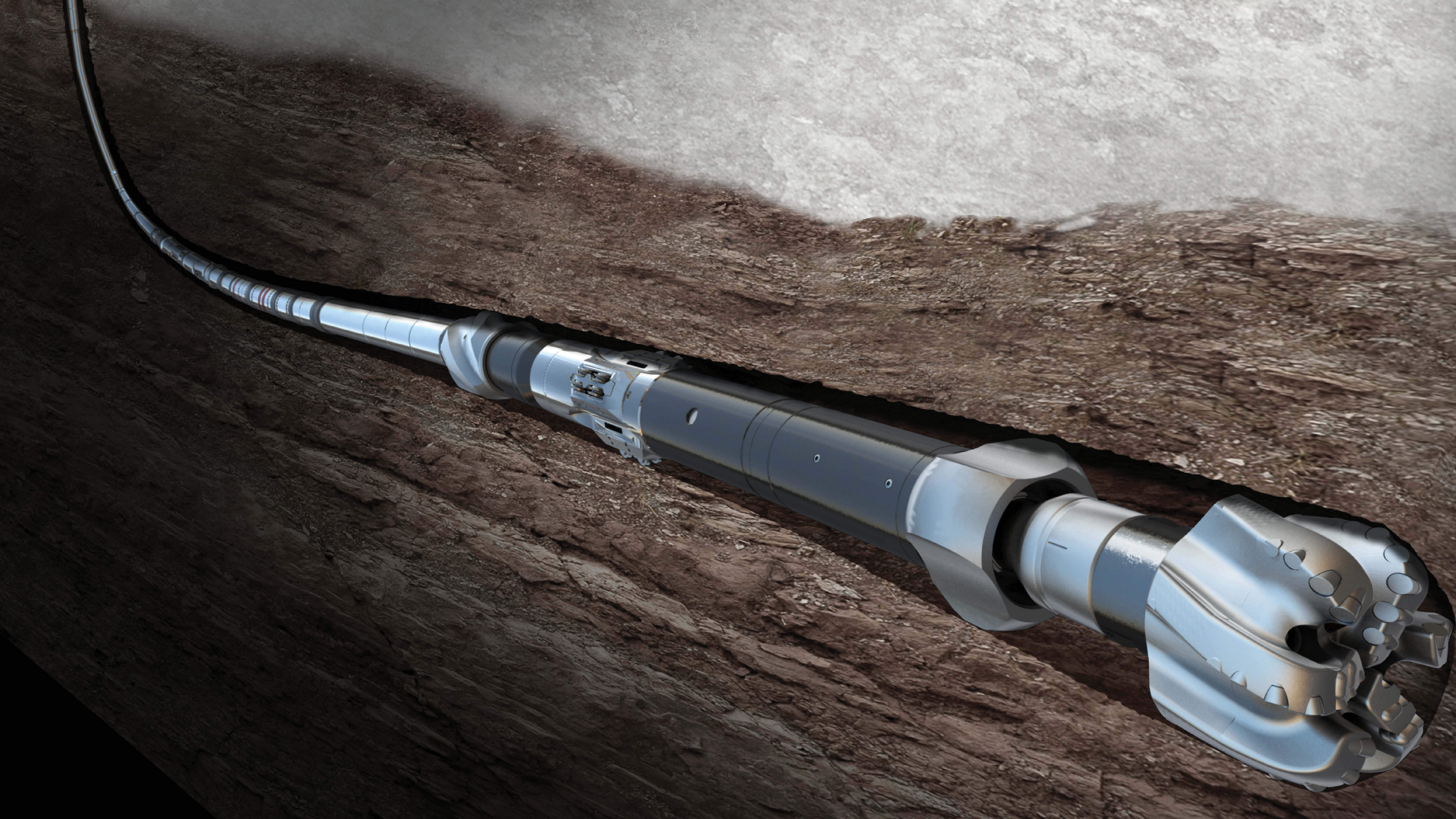

A major operator planned to drill an ERD well offshore Qatar with an 8½-in. lateral section of over 14,000 ft through a limestone reservoir, using a low solids, non-dispersed (LSND) water-based drilling fluid. The operator had drilled numerous offset wells through the same reservoir with LSND fluid, inclusive of a third-party lost circulation material (LCM). Seeking a more effective, customized solution, the operator wanted to evaluate the performance of an alternative LCM formulated and tested in Halliburton Baroids’s laboratory expressly for the planned interval.

The long 8½-in. horizontal section was to be drilled across a depleted, weak formation with 500 psi static overbalance. The well plan intersected several fault zones, where major lost circulation events could potentially occur. The main objective was to ensure wellbore stability under these conditions, and deliver a clean well for running a 7-in. liner to bottom.

Based on thorough laboratory testing, Halliburton Baroid recommended that 6 lb/bbl of BaraShield®-981 and 3 lb/bbl of BAROFIBRE O be added to the LSND fluid. This formulation exhibited tight filtration characteristics, low invasion potential, and superior return permeability results. The operator approved Baroid’s proposal due to the convincing laboratory test results. Baroid also suggested that BaraShield®-981 be added to the circulating system via premixed additions. Shaker screen selection was critical to maintain the target fluid properties and LCM concentrations in the active system.

The 9.2 ppg LSND fluid was prepared for the interval and displaced into the well. A concentrated LSND pill, comprising 45 lb/bbl of BaraShield-981 and 22.5 lb/bbl of BAROFIBRE O, was mixed in a reserve pit and bled into the active system. Maintenance treatments of the LCM materials continued through the interval via pre-mix additions.

Surface losses were minimized and LCM retained in the circulating system by utilizing the programmed shaker screen array. Fluid properties were also maintained while drilling. Total losses were encountered when intersecting a fault zone, as expected. To directly target this trouble spot, two LCM pills were pumped and squeezed into the loss zone, which reduced the dynamic loss rate to 80 barrels per hour (bph) with 200 gallons per minute (gpm). When two 30-bbl LCM pills with 35 lb/bbl of BaraShield-981 and 15 lb/bbl of BAROFIBRE O were pumped, the dynamic losses were further reduced to 50 bph with 480 gpm. The remaining 4,000 ft of the 8½-in. hole was drilled to the planned section total depth (TD), with a stable loss rate of 20 bph. The hole was circulated clean and the drilling assembly was pulled to surface without incident. The 7-in. liner was then picked up and run in a timely manner, without the need to ream down to bottom.

Minimal seepage losses were experienced while drilling this extended 8½-in. lateral with the 9.2 ppg LSND fluid containing BaraShield-981 and BAROFIBRE O additives. The total loss event at the fault zone was cured and the well was stabilized, so that the interval could be drilled to planned depth. Additionally, the superior wellbore conditions eliminated the need to ream down to bottom with the 7-in. liner.

Furthermore, the composite LSND fluid supported the tight filtration properties required for the interval. DEXTRID LTE consumption was 45 percent lower than the offset wells drilled using the third-party LCM, effectively reducing fluid maintenance costs.

Finally, the LSND engineered fluid solution had approximately 25 percent lower per-barrel cost than the average per-barrel cost for wells drilled with the previous LCM, maximizing the customer’s asset value and giving Baroid a clear competitive edge.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.