Search

Search

Search

Search

Engineered retrofit solution maximized asset value by keeping maintenance costs down

Download PDFIdentify root cause of motor and thrust chamber failures

The Permian - United States

A Permian Basin Operator contacted Summit ESP® to help fix two surface pump units at one of its saltwater disposal (SWD) facilities in West Texas. The customer had experienced several motor failures and high vibration on both surface units at this particular location. These issues needed to be addressed quickly with the customer’s goal of avoiding high maintenance costs associated with operating the SWD facility.

Initially, Summit ESP provided consulting services to witness what was happening to the SWD pump equipment and to deliver a better solution than competing vendors. We were able to identify the root cause of the problem and submitted a report with viable solutions in one day. Apparently, the current combination of equipment was exceeding the motor HP load—causing high vibration, and 800 HP motor and thrust chamber failures. The customer was so impressed with the findings that Summit ESP was given the go-ahead to implement the recommended plan.

The following obstacles had to be overcome:

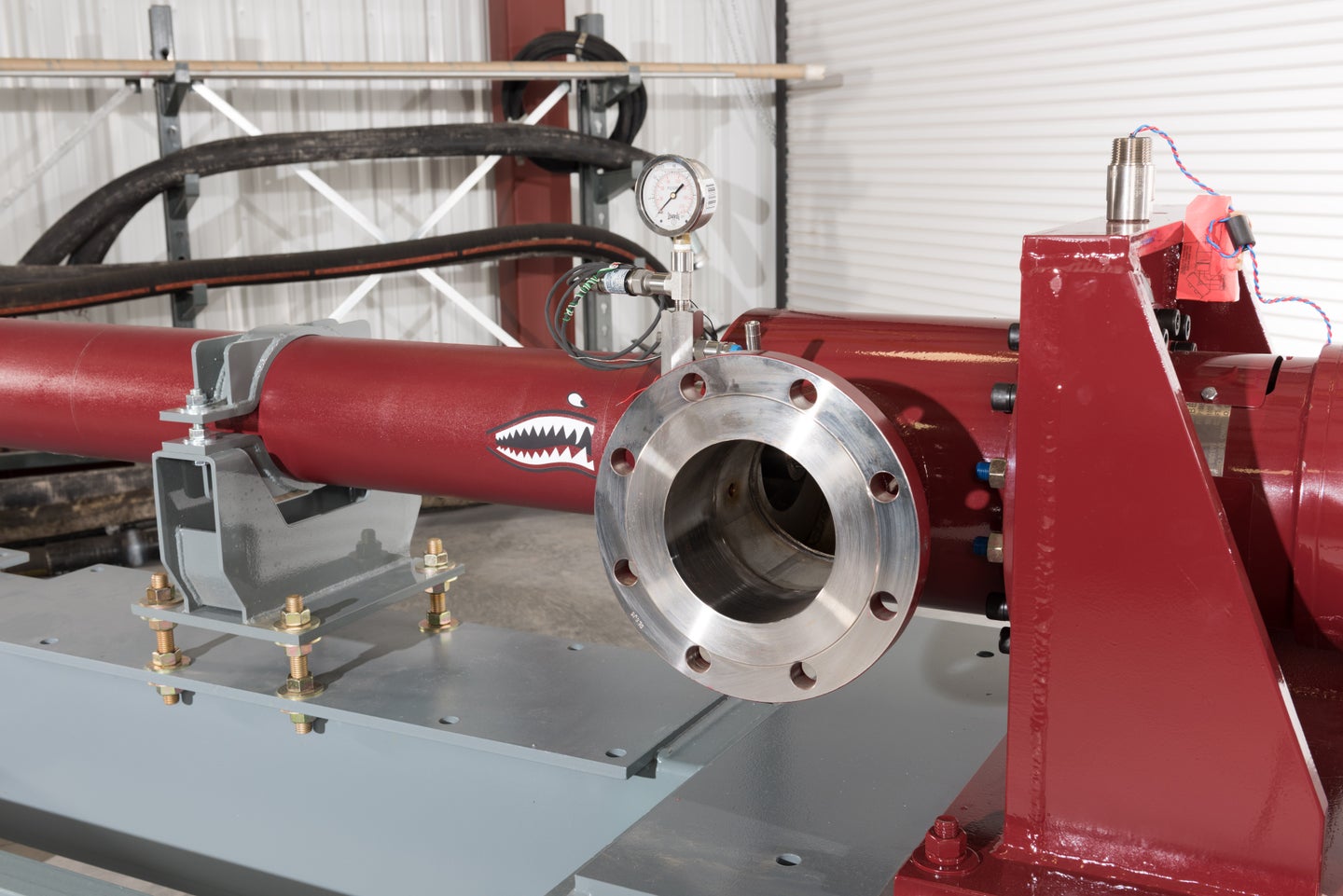

The solution was a complete intake, thrust chamber, and thrust chamber support bracket retrofit. This would allow the Operator to keep the majority of the existing system’s equipment and save on overall expense to restore units to their optimal operation points.

Summit ESP successfully resolved the presenting issues at this SWD location. The facility is now running at 100 percent operation and has gone without experiencing any further problems or non-productive time (NPT). This engineered retrofit solution maximized asset value by keeping maintenance costs down.

The Operator appreciated the customer service, knowledge, and experience that Summit ESP brought to the project. The operations engineer and field operations lead were especially impressed with our ability to understand their equipment. That, coupled with reacting quickly to their pressing needs, has positioned Summit ESP to keep working with the Operator to retrofit the rest of the identical units in its fleet, as well as provide quotes for the sale of new equipment.