Search

Search

Search

Search

Planned liner delivered in minimal time to set liner hanger and release running tool in complex HP/HT conditions

Download PDFMature Fields

Extended-reach wells

Continental Shelf

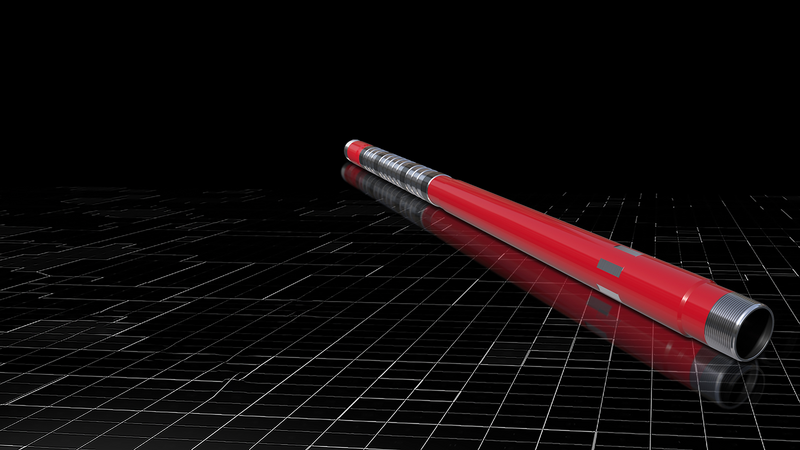

High-pressure/high-temperature (HP/HT) reservoirs pose multiple risks to wellbore construction. Halliburton mitigated these risks by applying an engineered solution that combined XtremeGrip® HP/HT expandable liner hanger (ELH) technology with 5.5-in. VersaFlex® dual cement plug sets both designed for these applications.

A major operator in Norway required a robust liner hanger solution to help ensure successful zonal isolation and a V0-qualified barrier under HP/HT conditions during well construction in two fields on the Norwegian continental shelf (NCS). The depth, trajectory, temperature, and stability of the wellbore introduced a combination of operational risks. The operator addressed these risks to ensure full section isolation with zero nonproductive time (NPT).

The increased tool capabilities, HP/HT ratings, and the hydraulic setting method of the Halliburton XtremeGrip® ELH system, combined with the 5.5-in. VersaFlex dual cement plug allowed the string to reach the planned section depth. This setup helped ensure proper placement of the cemented liner and liner hanger and allowed the running tool to release with greater efficiency during well barrier installation.

The extended-reach, highly deviated wellbore presented a narrow window for deploying and cementing the 5.5-in. liner. To mitigate risks and maintain wellbore stability, the team proposed managed pressure drilling (MPD) and managed pressure cementing (MPC) operations. These conditions required a liner hanger system capable of withstanding high external collapse pressure.

The extended-reach, highly deviated wellbore presented a narrow window for deploying and cementing the 5.5-in. liner. To mitigate risks and maintain wellbore stability, the team proposed managed pressure drilling (MPD) and managed pressure cementing (MPC) operations. These conditions required a liner hanger system capable of withstanding high external collapse pressure. The cement service provider could only achieve a static cement thickening time of less than one hour for the HP/HT design before the slurry became unstable.

This limitation left minimal time to set the liner hanger and release the running tool. The proposed top of liner depth exceeded 6,744 m (22,126 ft), and these fields required a robust cement plug and drillpipe dart system that would maintain positive displacement throughout the operation to help ensure cement placement per design. The top of liner depth and well trajectory also presented concerns related to weight transfer for successful deployment and release of the liner hanger running tool.

Previous attempts under similar well conditions to deploy, set, and release conventional liner hangers provided by other service companies resulted in liner top leakage.

Halliburton proposed the XtremeGrip® ELH system in corrosion-resistant material. The large bypass area of the XtremeGrip ELH reduced the surge effect and ECD during RIH and cement operations, which mitigated the requirement for MPD/MPC application. The high collapse rate of the system helped ensure the required backside pressure could be applied, if necessary. The XtremeGrip ELH system is a hydraulically set liner hanger with no requirement for weight to be transferred to the liner to successfully set the top of liner or release the running tool, which helped ensure these functions would not be compromised because of the depth and tortuosity of the wellbore.

Halliburton designed and performed qualification testing of the 5.5-in. VersaFlex® dual cement plug for the operator to meet the pressure and temperature ratings of HP/HT fields in Norway. The new design leaned on field-proven casing equipment technology using the robust MCXV darts, which provided the operator with the confidence for optimal displacement and cement separation.

To date, two successful installations have been completed using the high circulating pressure, rotational, and torque capabilities of the XtremeGrip ELH system. Rotation throughout the cement operation and the successful bump of the 5.5-in. VersaFlex dual cement plug, based on the calculated displacement volume, helped ensure zonal isolation as designed. Less than one hour after bumping the 5.5-in. cement plug and expanding the XtremeGrip ELH system, the team released the running tool. They then circulated the well clean, ensuring flawless execution of the highly engineered wells.

At the top of liner

5.5-in. dual cement plug in Norway

Climate installation sucessful

NPT/HSE/SQ issues

Halliburton delivered the planned liner hanger installation and overcame well challenges in this HP/HT climate with zero downtime. The XtremeGrip® ELH system, combined in conjunction with the 5.5-in. VersaFlex® dual cement plug enabled successful deployment, cementation, and expansion of the liner hanger while while maintaining wellbore integrity. With the reservoir formation isolated, the remaining well construction could be completed.

Operations in these fields for the operator involved Halliburton’s deepest liner hanger installations in Norway, with the top of liner ranging from 6,744 m (22,126 ft) to 6,858 m (22,494 ft). This was also the first installation of the 5.5-in. VersaFlex dual cement plug in Norway. Reaching section depth without the loss of wellbore integrity and achievement of competent well barriers via competent cement application and gas-tight isolation using the hydraulic set liner hanger system prevented NPT and unnecessary costs.

Halliburton now deploys XtremeGrip ELH systems with 5.5-in. VersaFlex dual cement plugs on numerous HP/HT wells in Norway, based on the success of this initial installation.

High-performance ELHs with enhanced hang-weight capabilities in elevated temperatures