Overview

Halliburton provided completion solutions for a subsea producer with several production challenges in the UK central North Sea. This infill development design was based on extensive experience with reservoir difficulties. Previous completions had a single gravel-packed interval and experienced water ingress from encroaching oil/water contact (OWC) and inability to stimulate due to lack of zonal isolation. The planned well was drilled as a sidetrack of a previous producer that was producing intermittently with high water cut. This almost vertical well was completed with less than 100 feet of producing interval.

Challenge

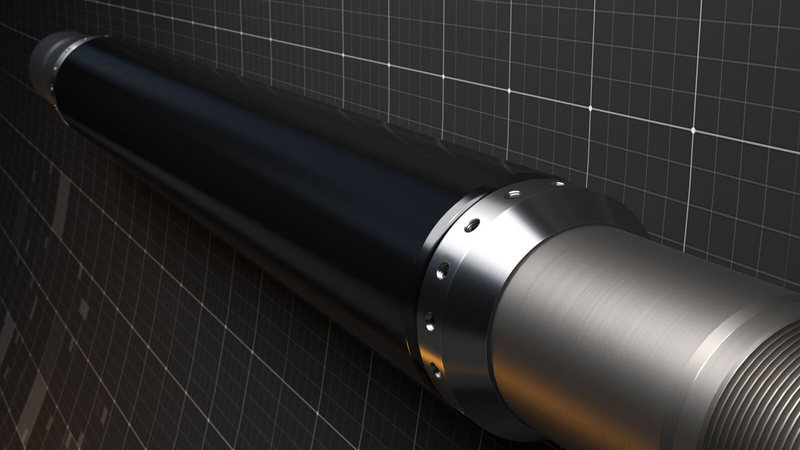

Halliburton was tasked with providing several compatible modular options to complete a robust well, address several eventualities and mitigate the need for future intervention. The options included selective Sliding Side-Door® screens, wire-wrap screens, hydrostatic ZoneGuard® HE openhole packers and slip-on oil-swelling (OS) and water-swelling (WS) Swellpacker® systems.

Solution

- OWC: Combination of a Zoneguard HE (High-Expansion) packer and Swellpacker WS system installed below the screens. This application provided dual benefits — water control and the sump for the gravel pack. Within the performance target drilling, the rathole is dependent on log results and cannot always be controlled

- Selective gas cap production: Combination of ZoneGuard HE packer and Swellpacker OS system to provide zonal isolation and PoroMax® Sliding Side-Door® screen to providesand control and selective production.

- Oil zone sand control: PetroGuard wire-wrap screens in conjunction with 20/40-mesh gravel pack to provide reliable sand barrier.

- Zonal isolation: Slip-on Swellpacker® system that allows for drill floor changes to the completion design, optimizing production for a limited payzone.

Search

Search

Search

Search