Search

Search

Search

Search

New technology improved targeting, reduced costs, and kept samples under pressure so hydrocarbons could be accurately measured

Download PDFUnconventionals

Returning samples to surface without losing fluids

Ohio and West Virginia

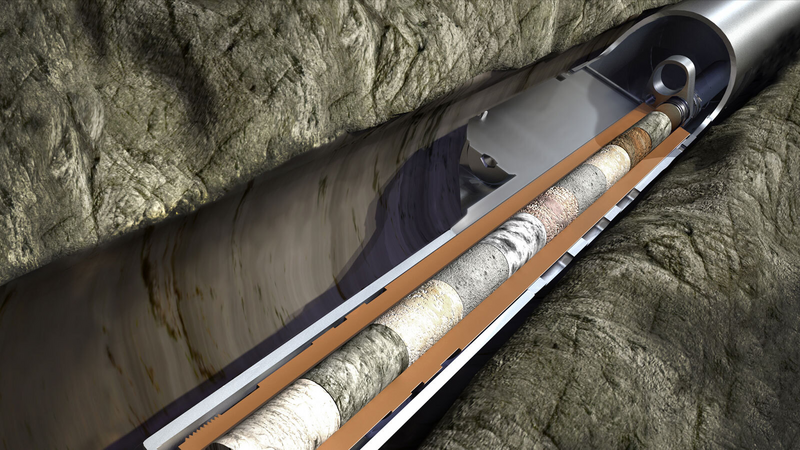

Accurate economic evaluation of a shale well previously required drilling and completing it. Traditional coring tools let fluids escape from samples as they depressurized. As a result, analysis had to be based on estimates of fluids lost rather than measurement of fluids in place. Also, tools could take days to retrieve just one core. New Halliburton CoreVault technology is changing all that, however. Built into the next generation of the proven Xaminer Coring Tool, the CoreVault system can capture up to 10 samples in a sealed container – in one run. The container prevents reservoir fluids from escaping during core retrieval and transport. An operator in Ohio and West Virginia used the system to retrieve 150 samples in five wells. Measurements of samples obtained with the CoreVault system showed 2.5 times more oil and gas in place than previously estimated. The operator also found variability in organic content, enabling better targeting and completion efficiency

Unconventional wells vary widely in their performance – even when the wells are in the same field. Historically, one third of perforation clusters fail to produce any oil or gas, while another third of the wells account for 75% of the total production. To improve drilling efficiency and reduce costs, operators need to gather more accurate information about the location and volume of hydrocarbons so they can avoid spending millions of dollars fracturing a well that may be a dry hole. Most traditional sampling tools lose pressure in core samples, so as samples are brought to the surface, much of the fluid escapes. On average, 50-70% of the hydrocarbons in a core sample are lost before they can be analyzed.

An operator in Ohio and West Virginia chose to use CoreVault technology from Halliburton. It seals core samples into a pressure vessel at depth. Using this the new system ensured that core samples remained sealed, preventing fluids from escaping. This gave the operator the ability to take a true measurement of the fluid volume in the reservoir instead of relying on inaccurate estimates. Halliburton has also developed an overpack transportation solution that allows safe handling of the pressurized cylinders. Despite the high pressure inside the cylinder, once packed appropriately, the operator was able to safely ship the samples by air to remote laboratories for analysis.The CoreVault system is built into the latest generation of the field-proven Xaminer Coring Tool. This tool takes just minutes to retrieve each sample, and can take up to 10 samples in just a few hours. This enabled the operator to take cores from multiple points in each well and to see where the most profitable zones were – without having to fracture the entire well.

The operator ran the CoreVault system in five wells, gathering a total of 150 core samples. Previously, the operator estimated fluid loss from depressurized samples. Calculations, based on the faulty estimates, indicated an average of 78.2 scf/ton of hydrocarbons in the reservoir. Samples retrieved by the CoreVault system revealed an average of 196.2 scf/ton. That meant the operator had 2.5 times more gas than expected. Thus, the CoreVault system enabled much more accurate valuation of gas in place. It also enabled better targeting because it retrieved multiple samples from different places along the wellbore. Using conventional tools, the operator could have concluded that these wells would not be economic. But thanks to CoreVault technology, the company knew the precise volume of oil and gas in the reservoir. The operator also obtained better information about where the most profitable zones were. That enabled the company to complete wells more efficiently and avoid fracturing nonprofitable zones and dry holes. Thus, CoreVault technology contributed to more efficient use of capital

The CoreVault™ solution keeps rock samples in a sealed container, so 100% of the fluid in the core sample will be preserved for analysis.

Examine the smallest pores and characterize formations using high-resolution, best-in-class magnetic resonance logging.