Search

Search

Search

Search

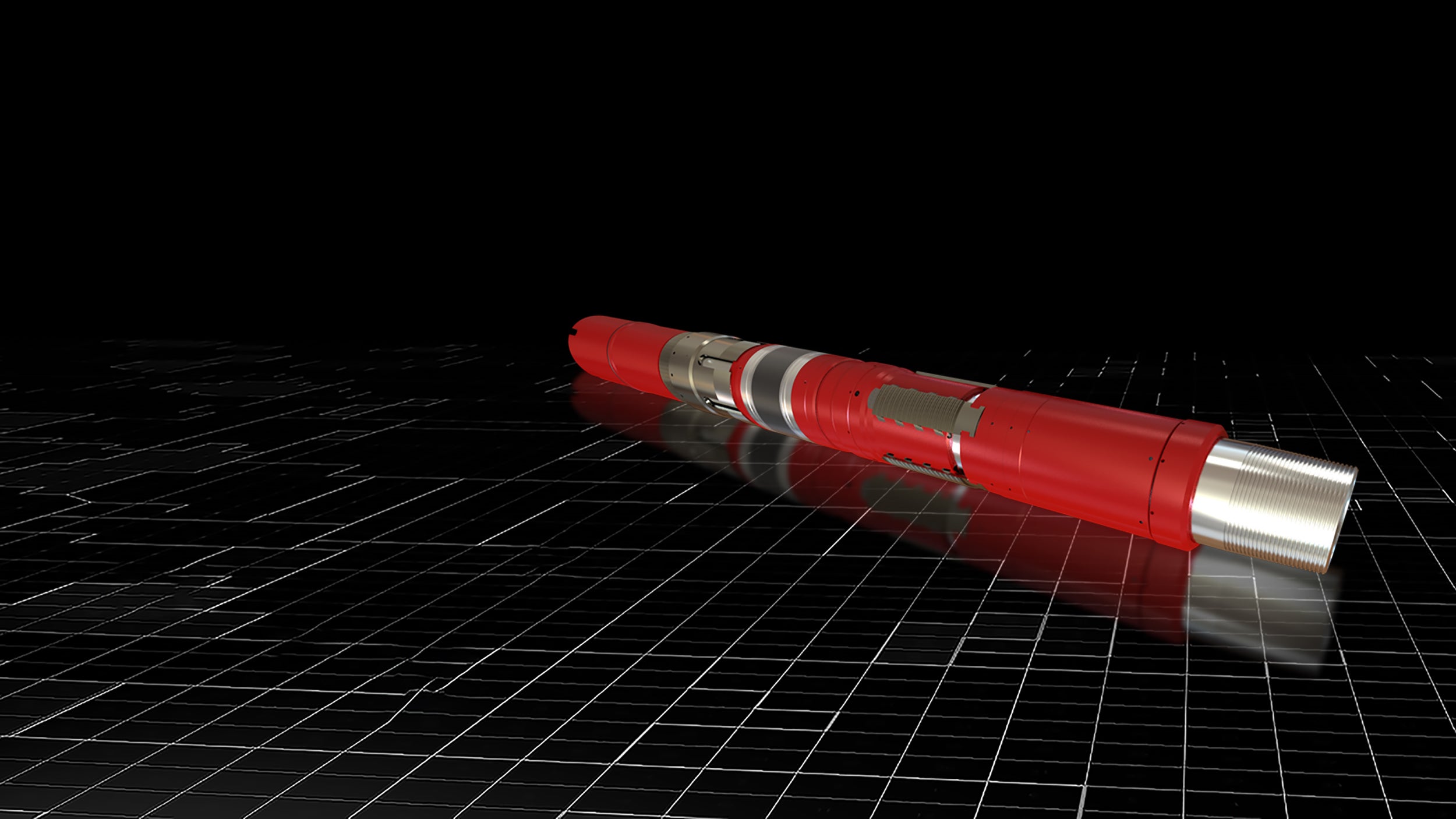

4.5 × 7-in. conventional MatchSet® liner hanger packer system successfully deployed in the Bakken Shale formation

Download PDFMature Fields

Deploy floated-in liner for extended-reach horizontal wellbore applications

North Dakota

A major operator successfully deployed the MatchSet® liner hanger system in a Bakken well campaign to overcome challenges posed by long lateral sections during wellbore construction. Obstacles faced, solutions implemented, and results achieved using the MatchSet liner hanger packer system over seven successful installations are highlighted. The operator deployed its longest floated-in liner to date in a cemented production liner application, and the longest deployed in the region thus far for Halliburton using the MatchSet liner hanger packer system (liner length of 16,544 ft, liner shoe MD of 26,595 ft).

Wells in the Bakken are known for extensive lateral length and present unique challenges during well completion with floated-in liner applications. The environmental factors, which include high pressure, horizontal deviation, and elevated temperatures, add to this complexity. The need for floated-in liner during this operation was essential because of the substantial length of the laterals, which exceeded typical operational parameters. It was critical to the success of the operation that the liner hanger system could handle these demands.

Halliburton collaborated with the operator to understand the presented difficulties. Together, they tailored an engineered solution that leveraged the MatchSet liner hanger packer system, specifically a 4.5 × 7-in. production liner hanger packer system. Known for its proven track record and qualification in floated-in applications, Halliburton rigorously tested this system to validate performance under the specific conditions of the Bakken wells before deployment.

As part of the equipment selection, in addition to a MatchSet conventional liner hanger packer, Halliburton deployed a landing collar and RapidStart® toe sleeves for the completion. The MatchSet hanger was deployed with water-based mud in the wellbore, cemented in place, and subsequently displaced with 10-lbm/gal brine. This collaborative approach and the selection of the MatchSet liner hanger packer system provided a cost-effective solution that surpassed other potential options.

ft liner

ft liner shoe MD

floated lateral

NPT or COPQ

Deployment of the MatchSet liner hanger packer system yielded impressive results. Notably, more than seven successful runs were performed, including the longest floated-in liner deployed by the operator to date (liner length of 16,544 ft, liner shoe MD of 26,595 ft). These achievements not only demonstrate the robustness of the system but also highlight significant operational efficiencies. There was zero nonproductive time (NPT) or cost of poor quality (COPQ) during the deployment. The capability to float in such long liners without complications translated into substantial time and cost savings for the operator. Through reduced operational downtime and increased efficiency, the MatchSet liner hanger packer system provided a cost-effective solution that delivered significant financial benefits.

This case study highlights the proven capability of the MatchSet liner hanger packer system to address the rigorous conditions of Bakken wells as part of a cost-effective and collaborative solution. The operational objectives were met with a tailored engineered approach that delivered cost savings with zero NPT or COPQ.

Liner Hangers

The MatchSet mechanical-set conventional liner hanger with integral liner-top packer has a unique compact design for wells drilled in pressure-sensitive formations. The hanger is equipped with a mechanical setting mechanism in a solid body mandrel design with no hydraulic setting ports or leak paths.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications