Search

Search

Search

Search

Intelligent satellite Edge device enable remote ESP control and connectivity in isolated Vaca Muerta shale

Download PDFUnconventional

Remote wells with limited cellular access challenge real-time ESP management

Argentina

Wells located in remote areas with limited cellular availability present challenges for customers who need real-time management of ESP operations

The Vaca Muerta formation represents Argentina’s largest and most prominent unconventional shale play. Despite various attempts using artificial lift methods, the formation’s production potential has yet to be fully optimized.

Operators have determined that ESPs have the potential to double the production of other artificial lift methods. As their feasibility is explored, the significance of remote monitoring and control becomes even more pronounced, especially in isolated locations. However, operators who choose ESPs as the primary lift method in such remote areas encounter challenges due to limited SCADA availability and functionality and constraints related to cellular signal strength.

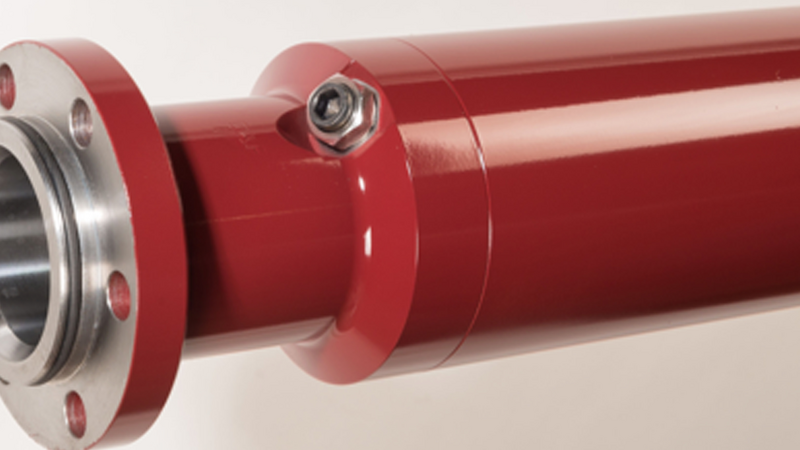

Halliburton designed a cutting-edge ESP system and monitoring solution to address all the customer’s production needs. The ESP system design included a 338 series Tiger Shark pump and Defender® seals with a 375 series motor to tackle the high production volumes and fluctuations in gas-liquid ratios (GLR).

Intelligent Edge devices offered connectivity and data backup when needed, which was necessary given the project’s isolated location. A VSD equipped with gas lock operating mode and analog inputs would ensure that the well could be monitored and remotely optimized via the Intelevate platform.

The implemented solution targeted all the challenges identified before the ESP install and provided 24/7/365 surveillance and full remote controls for operating modes setup (set Hz, gas lock, proportional integral derivative, extended ramp, locked pump, etc.), surface valve adjustments (tubing choke), and drawdown monitoring. The assessment of operating status based on health checks, such as motor current stability, vibration, daily drawdown, and pump operating point, could be done remotely.

This was the first Summit ESP® installation in the Vaca Muerta Shale, and all the customer’s goals were achieved. The customer was pleased and complimented the teamwork and more than a dozen departments within the operating company, congratulating them all on the great milestone achieved together. This recognition is a testament to our collective efforts and commitment to excellence.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.

Defender® seals extend the operational life of motors used with ESPs by equalizing downhole pressure and preventing wellbore fluid migration to the motor.