Search

Search

Search

Search

Longest onshore well in the UAE at 32,300 ft

Download PDFMature Fields

Drill first onshore ERD well in the UAE

Abu Dhabi, United Arab Emirates

In continued pursuit of optimized production, ADNOC Onshore sought to maximize reservoir contact by planning the first extended reach drilling (ERD) well in the company’s history. The well was targeted to reach an onshore record of 32,300 ft measured depth (MD), significantly beyond any prior well depths for the operator. Halliburton Abu Dhabi was entrusted to provide integrated drilling services for this critical first well, harnessing experience in ERD operations in the area. A multidiscipline Halliburton team, comprising personnel from multiple Halliburton product service lines (PSLs), collaborated with ADNOC Onshore to engineer an optimum well design and successfully drill and complete the longest onshore well in the UAE—meeting the project objectives of 32,300 ft MD and a greater than 20,000-ft lateral drain—and doing so ahead of the AFE planned well duration.

Prior wells in the field had succeeded in penetrating the target reservoir; however, no comparable well length had ever been attempted. Uncertainty in directional response, bit durability, equivalent circulating density (ECD), and induced losses were the main areas of concern for the extended lateral section. Other concerns included friction, torque and drag, and overall rig capacity in this unknown environment. Additionally, there were significant concerns regarding intermediate sections due to a weak formation with high fluid loss potential during drilling and cementing activities.

Exhaustive offset well analysis was performed by the combined Halliburton teams to determine opportunity areas for maximizing drilling performance and extended reach in the field—including the bottomhole assembly (BHA) formational tendency, drilling fluid properties for enhanced hole stability and zero formation damage, operational best practices, and cement slurries designed for heterogeneous formations.

The well planning process included technology tool selections based on specific objectives, cost benefit analysis, the Drill Well on Paper (DWOP) process, peer reviews for the final drilling program, pre-spud meetings in the office, and, finally, spud meetings in the field.

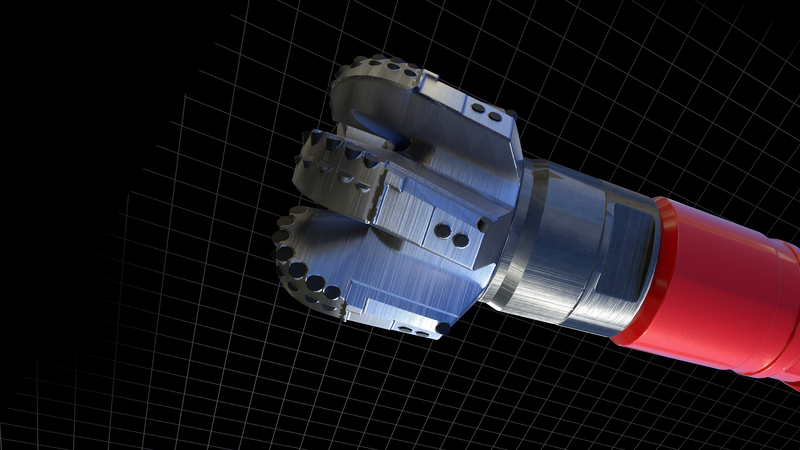

The integrated Halliburton approach yielded complementary solutions across drilling services, with a focus on reducing risk and optimizing performance from a total well perspective. The engineered solution included customized GeoTech® drill bits via the Design at the Customer Interface (DatCI℠) process, ensuring high impact and abrasion resistance, along with rotary steerable system (RSS) compatibility.

The drilling BHA utilized the iCruise® intelligent RSS and the LOGIX® automated drilling solution for precise directional drilling. Also utilized were the DrillDOC® drilling downhole optimization collar, and the combined MRIL®/XBAT™ logging-while-drilling (LWD) tools to support geosteering requirements while also reducing risk. The iCem® cementing service modeled NeoCem™ flexible expandable cements to optimize ECD. Specially formulated drilling fluids, including BaraXcel™ drill-in fluids and BaraLube® drilling fluid additives, were supported by DFG™ modeling software for optimized hole stability. The Halliburton team used the ADT® drilling optimization service, along with the HalVue™ real-time viewer, which provided 24/7 access to the drilling data.

ERD Well Onshore UAE

FT Total Depth Record

Reservoir Contact

ROP Improvement

The first ERD well in the field was drilled successfully and significantly ahead of plan, achieving a record as the fastest and longest 12¼-in. hole and 8½-in. well sections drilled in the field to date, along with the record of the longest onshore well at 32,300 ft MD.

The 20,018-ft lateral section was geosteered to precision with 100% reservoir contact and seamless correlation between source and sourceless BHA runs. The custom-designed bits stood up to the extended drilling (coming out in “green” condition and ready to re-run), and achieved the footage record with a 29% improvement in rate of penetration (ROP) versus the field average.

The BaraXcel fluid and DFG modeling helped maintain the ECD below the frac gradient throughout the lateral section. Hole cleaning was optimal without cuttings buildup or tight hole, despite some rig limitation in RPM. Friction factors (FF) while pulling out of hole with the BHA after displacing the well to completion brine were reduced to below 0.15 FF, thus reducing the torque and completing the well without issues.

The iCem-modeled cement job—utilizing the mechanically robust NeoCem™ lead slurry and flexible, expandable tail slurry for casing cement jobs—enabled zonal isolation against traditionally weak formations. This resulted in cement to surface while maintaining shoe integrity. Successful zonal isolation of the 9⅝-in. cement job through utilization of tailored cement slurries resulted in excellent cement bond logs (CBLs), setting up critical support for extended 8½-in. lateral drilling.

Due to these outstanding results, ADNOC is confident in the ability of Halliburton to execute such challenging wells in the onshore environment, and is looking toward additional wells to expand the ERD campaign.

Halliburton collaborates with all stakeholders to develop a robust design and an effective program tailored for each well construction project.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.

NeoCem™ cement is a low-Portland cement system that provides shear bond at lower density and greater elasticity.