Search

Search

Search

Search

Horizontal pumping system technology and field service combine to increase recoverable oil and gas reserves

Download PDFUnconventionals

Maximize recovery of oil reserves in unconventional and mature fields.

Rocky Mountain Region

Halliburton Summit ESP® has been successfully applying its CO2 booster pump for enhanced oil recovery (EOR) projects in the Rocky Mountains region of the U.S. for the past several years. This durable electric submersible pump (ESP) is a specially designed horizontal pumping system (HPS) that, when used in combination with Summit’s expert field services, significantly increases recoverable oil and gas reserves in mature fields. This same CO2 injection technique can also help with the growing need for carbon capture and storage (CCS).

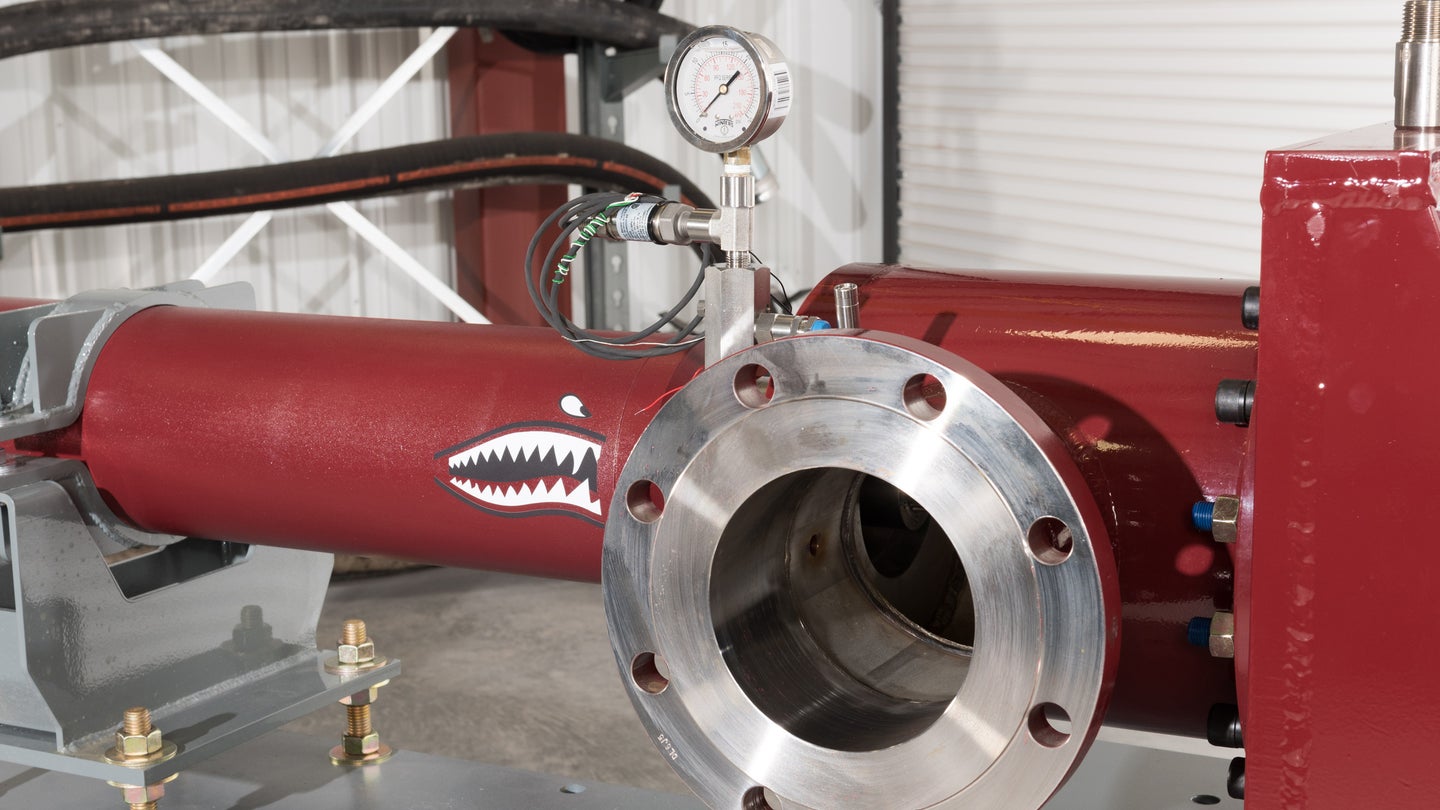

Summit ESP introduced an HPS product line in 2016. Building upon existing customer relationships, trust was built by first servicing competitor units and then selling water injection HPS units directly to the same customers. This opened the door for recommending higher-specification CO2 pumping, with the first order being the installation of a 2,000-psi, 15-stage SN35000, 800-hp HPS unit that could pump approximately 1,000 U.S. gallons per minute (gpm). In this case, the customer had overestimated the production volumes, as revealed after the HPS installation. Fortunately, Summit’s flexible HPS design can be easily adapted for changing operating conditions.

Therefore, despite the actual requirements being one-third of the original flow rate, Summit ESP field service technicians were able to quickly retrofit the updated 37-stage SH9000 pumps to the existing skid to efficiently produce the lower flow rate, while minimizing the additional capital cost to the customer. For most other pump technologies, the entire pump system would have had to be replaced at a significantly higher cost and with an extended lead time. The unique design of the Summit ESP CO2 booster pump assembly provides the additional benefit of allowing the original pump to be reinstalled, if needed, to accommodate increased flow rates in the future.