Search

Search

Search

Search

Operator optimizes production rate and avoids sand production in depleted reservoir

Download PDFUnconventional

Potential risk for sand production to reduce production rates

Norway

Sand migration in a reservoir can present major obstacles to well production through reduced production rates, sand bridging, equipment erosion, and sand disposal and removal. The potential for sand production is elevated in depleted reservoirs, as was the case for a North Sea operator. Risk associated with reduced production rates increased in a deviated wellbore, a factor that complicated the primary completion strategy to perforate with oriented gun systems.

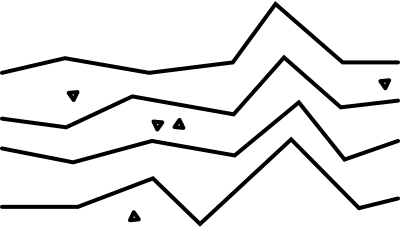

Typically, oriented perforating guns shoot charges perpendicular to the gun body and wellbore. This works well in a horizontal well. But the 59° deviation in this well posed a challenge that no gun system on the market could address. The previous solution was to use standard G-Force® perforating gun systems. However, they did not shoot into the plane of maximum stress.

Halliburton created a new gun system based on the existing 3 1/8-in. G-Force system design. This unique solution perforates in the direction of the maximum stress in the formation and allows the charges to exit the gun at an inclined angle.

The gun system was deployed on drill pipe in a tubing-conveyed perforation (TCP) shoot-and-pull operation. Quick torque connectors (QTCs) were used to avoid operating in the red zone to help reduce risk and increase efficiency.

Inclined gun system used to perforate well

Sand production

Production decline

The custom G-Force inclined gun system worked as designed and perforated the well. Initial results validated the theory that vertical perforating could be attained to reduce sand production risks. No significant shock hazard was observed during perforating. The well produces as expected with zero sand production and no decline in production rate.