Search

Search

Search

Search

Comprehensive collaboration delivers efficient, scalable system with minimal capital expense in half the time of alternative solution

Download PDFRapid need to increment their water injection capabilities by 300%.

Colombia

A Colombian operator faced the critical challenge of rapidly addressing their increasing need for water injection to meet their production target demands.

The customer’s current water injection infrastructure was based on an HPS system with a nominal capacity to inject 35,000 BWPD. Their initial replacement strategy of increasing capacity presented operational challenges and bottlenecks due to the number of units that would be required. Recognizing the urgency of the situation, the customer decided to seek out a partner who could rapidly address their immediate challenges with a single-unit solution that could inject 80,000 BWPD and would also address long-term growth objectives.

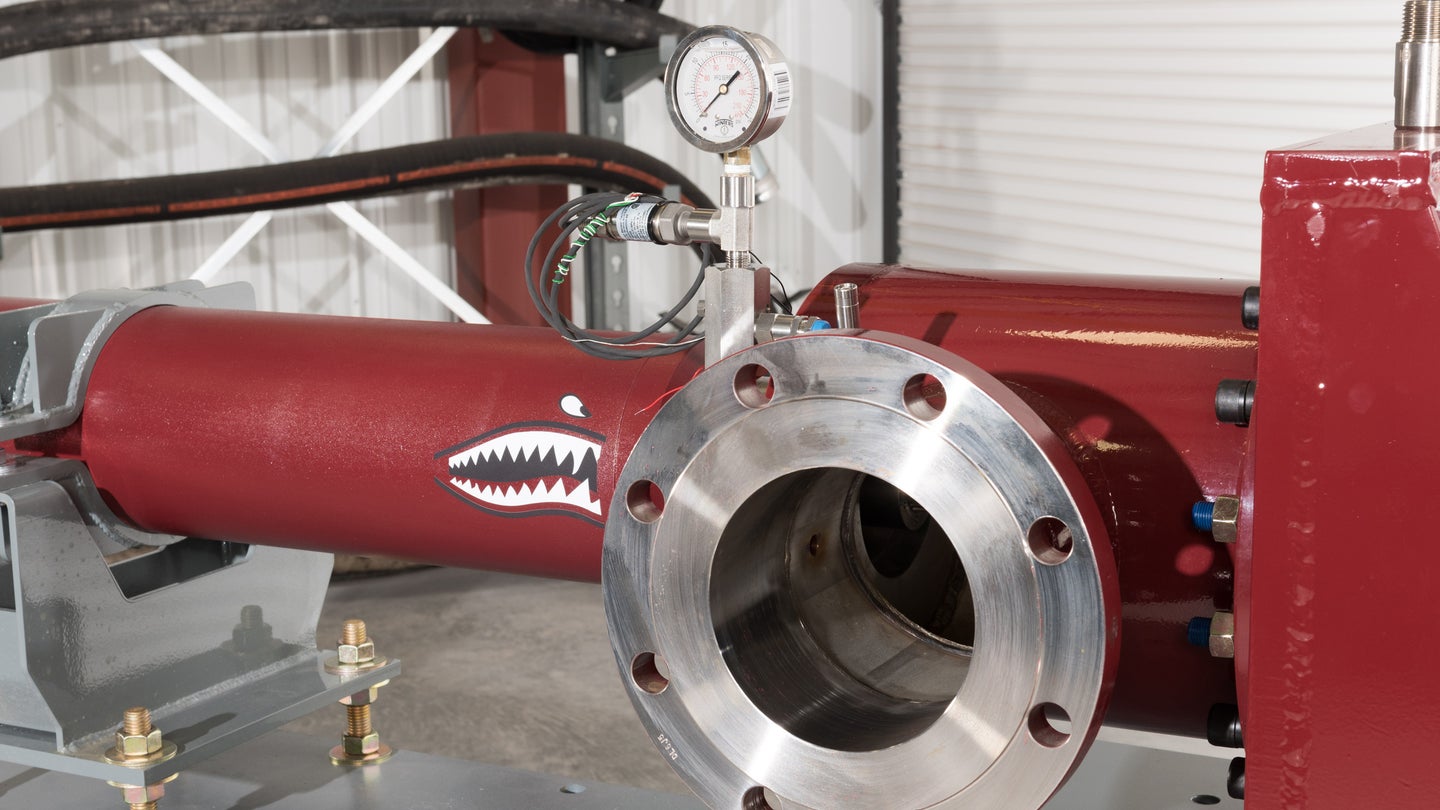

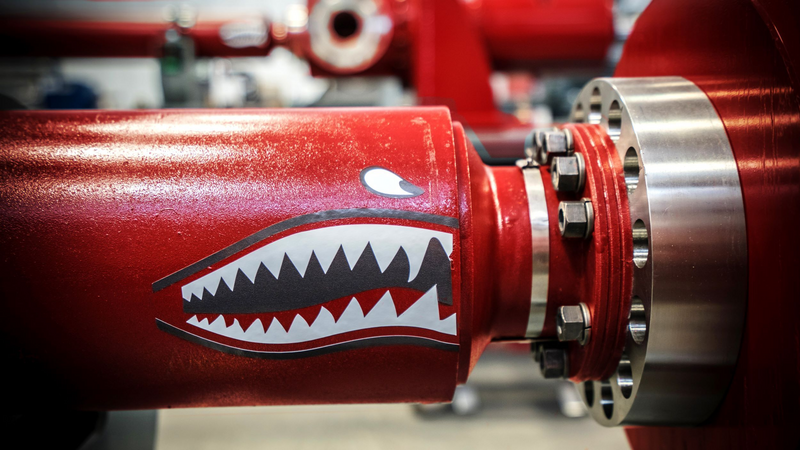

Summit ESP® - A Halliburton Service engaged in a comprehensive collaboration with the customer to understand their specific requirements, challenges, and goals. Halliburton proposed a tailored solution that would expand and modernize their current injection system with a single wide range, high efficiency, high flow Hercules™ horizontal pumping system (HPS.)

With a nominal capacity of 80,000 BWPD up to 100,000 BWPD, Hercules HPS tripled the production of their current single-unit systems and would be able to handle varying reservoir conditions. It negated the expense of buying multiple replacement units and was designed to seamlessly integrate with the customer’s existing facilities, minimizing downtime during the implementation phase. Designed with a best efficiency point of 88% versus 77-79% for alternative systems, the customer would also benefit from significant power savings.

With the expanded water injection capabilities in place, the customer significantly enhanced their capacity to increase oil production. The scalability of the new system allowed them to adapt to changing project requirements and market dynamics seamlessly. The collaboration between the customer and Halliburton not only addressed the immediate challenges but proved Halliburton’s prowess with larger, more complex water injection horizontal pump system solutions. As a result, the customer has placed orders for two more identical units.

HPS unit solution used

BWPD injection

Production increase

Power cost savings

Pump more efficiently with a focus on lower maintenance costs, longer operational life, and 24/7 monitoring