Search

Search

Search

Search

New TAML Level 5 FlexRite® MIC system enables more possibilities for advanced multilateral completions

Download PDFDeep Water

Develop a MLT solution for operator's mature field in the North Sea

North Sea, Norway

Designed and developed the 9 5/8-inch FlexRite MIC system, which was the first TAML Level 5 junction of its kind:

In the late 1990s, Halliburton partnered with a major North Sea operator to develop and install multilateral technology (MLT) systems in one of Norway’s large offshore oil fields. This initial collaboration eventually led to the development of the first TAML Level 5 FlexRite multilateral system in 2001.

Halliburton has since completed in excess of 300 FlexRite installations for this operator, using different FlexRite junctions. The most notable of these has been the 10 3/4-inch multibranch inflow control (MIC) junction, which allows selective branch control of multiple laterals. In late 2018, Halliburton celebrated its 100th FlexRite MIC installation in the North Sea.

In March 2017, this same Norwegian operator approached Halliburton, needing a new TAML Level 5 MLT solution for its mature field in the North Sea. While the operator had been using Halliburton MLT technology successfully for many years in this field, its use was limited to individual branch control in dual lateral applications, as well as comingling from additional branches in tri and quad lateral wells. The operator asked Halliburton to create up to three and four laterals from 9 5/8-inch casing, which would help increase overall reservoir exposure, while still maintaining the selective control and monitoring of each individual lateral. At the time, a system with this functionality in this size did not exist globally.

Halliburton has a long history of collaborating with this Norwegian operator to develop MLT solutions to address its field challenges. The Halliburton 10 3/4-inch FlexRite MIC junction has had a proven track record, and was the first TAML Level 5 junction of its kind to allow intelligent completion components to be run through the junction. This proved to be a significant step change in the possibilities for advanced completion solutions and selective, remote branch control.

In mid-2017, Halliburton began working with the operator to design and develop a completely new FlexRite MIC system for 9 5/8-inch casing. The new junction had to be compatible with an intelligent completion solution to provide selective control of each lateral.

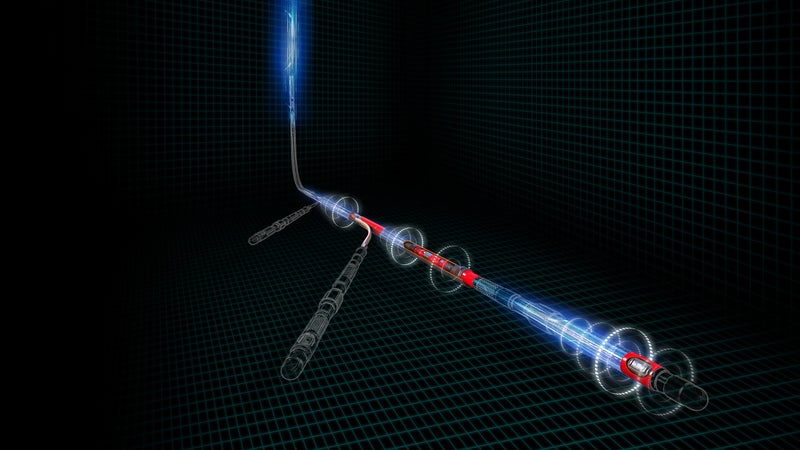

In less than two years, the new FlexRite MLT and intelligent completion system was designed, qualified and tested, and was ready for initial deployment. The new system featured multiple stacked 9 5/8-inch MIC junctions, with an accompanying 2 7/8-inch intelligent completion solution. The completion design incorporated swellable packers for isolation between laterals, along with interval control valves (ICVs) and gauges for the remote control and monitoring of individual reservoir branches.

This new solution would allow an unlimited number of MIC junctions to be installed in a given well, using the new FlexRite MIC system. Now, production or injection can be managed and controlled at each individual lateral, totally independent of all other lateral legs.

Installation of a 9 5/8-inch quad lateral MIC junction

since completed FlexRite installations

completed in the North Sea

Halliburton completed the first installation of the 9 5/8-inch FlexRite MIC junction and the accompanying 2 7/8-inch intelligent completion system for the Norwegian operator in May 2019. The development of this new solution opened the door to achieving selective control and monitoring of individual laterals from 9 5/8-inch casing. The new junction featured a large drift diameter throughout the entire mainbore, allowing for a single-trip final installation of a 2 7/8-inch intelligent completion string, featuring HS interval control valves (HS-ICVs) and DataSphere® ROC™ permanent downhole gauges.

This completion marked the world’s first 9 5/8-inch quad lateral well with selective branch control and the ability to manage production from each of the individual branches, in the event of a gas influx or water breakthrough, without impacting production from other laterals. The FlexRite MIC system helped increase reservoir exposure for the field, provided branch control of multiple laterals from the 9 5/8-inch casing, and maximized production from each multilateral leg – contributing significantly to the reduced overall cost per BOE.

The ability to achieve individual zonal control for multiple stacked MLT junctions from 9 5/8-inch casing opens new opportunities for many fields globally. This new completion solution unlocks new possibilities for mature fields, as well as for new field developments. This has particular relevance and potential for mature fields, where slot recovery and recompletion are being considered. As the industry is moving to develop more complex and challenging plays, technologies such as this can play a vital role in maximizing reservoir exposure and control with minimal topside infrastructure and reduced overall cost.

MULTILATERAL SYSTEMS

The FlexRite multilateral completion system is used to create a TAML Level 5 multilateral junction in wells that require hydraulic pressure isolation, sand control, and mechanical integrity at the junction using completion design.

Download Data Sheet

Intelligent Completions

Halliburton DataSphere ROC permanent downhole gauges (PDGs) help increase productivity through the life of the well or reservoir by providing reliable, real-time permanent monitoring of downhole conditions.

Download Data Sheet

Greater profitability and a higher return on investment with innovative multilateral technology

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value