Search

Search

Search

Search

Customer proves viability and recovery of resource with formation evaluation, well bore drilling, and completions

Download PDFDirect Lithium Extraction

Help expedite customer's entry to the DLE market ahead of its competitors

Smackover Formation

With plans to enter the Direct Lithium Extraction (DLE) market ahead of its competitors and become a leading lithium producer, a Halliburton customer began an appraisal project in southwest Arkansas. The customer planned to drill six vertical appraisal wells, one demonstrator producer well, and one demonstrator injector well to confirm the project’s viability and gather information for future field development. Brine was tested from deep underground to understand lithium concentration and variability, brine quantity, and production feasibility.

The necessary brine for lithium production resides thousands of feet below the surface, and the geology of southwest Arkansas poses formation evaluation challenges. The reservoir’s varied lithologic profile ranges from laminated carbonate mudstones to dolomitized grainstones and packstones, which makes it difficult to predict productive zones. Despite these factors, the customer needed to confirm the available resources, reservoir quality, deliverability, and pore space volumes and connectivity. They also wanted to understand the subsurface distribution of lithium concentration in the target formation and determine the current reservoir pressure and the impact of adjacent project injectivity.

The customer granted Halliburton full access to all internal planning meetings and processes to increase collaboration with the integrated services team. This allowed both teams to respond quickly and efficiently to changes in drilling, evaluation, and completion plans.

To start the project, Halliburton provided a comprehensive geohazard analysis with in-depth offset well drilling hazard identification, geomechanics overview, pore pressure and fracture gradient charting, days vs. depth estimation, and a geoscience/subsurface assessment of the project area and its suitability.

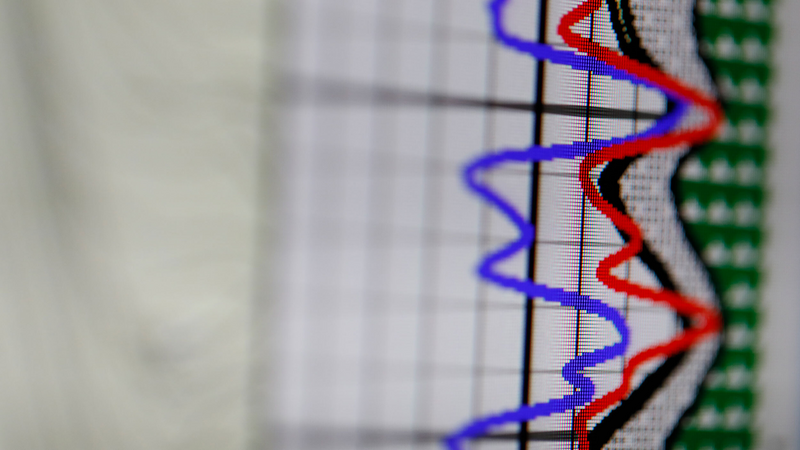

By combining traditional techniques such as resistivity, density, neutron, gamma ray, and ultrasonic imaging, Halliburton was able to acquire a more complete understanding of the formation. Halliburton used three wireline technologies for formation evaluation: the Xaminer® Magnetic Resonance (XMR™) service to understand the free fluid volume and porosity distribution; the Reservoir Description Tool (RDT™) to understand zonal pressures and mobility and obtain fluid samples; and the Xaminer® Array Crossed-Dipole Sonic Tool (XAST™) for deep imaging to understand fracture connectivity and conductivity. This combination of data and Halliburton’s ability to integrate it allowed the customer to characterize the formation and validate the field’s viability for lithium extraction.

“If you didn’t know this was a lithium project, you’d think it was a logging program for an oil or gas exploration well,” a chief geoscientist at Halliburton remarked.

Halliburton ran rotary sidewall cores on most of the exploration wells. This provided more cost-effective rock samples compared to the whole core. The flexibility of the rotary coring service to change bits allowed the customer to achieve high recovery rates. They observed changes in the rock mineralogy over the sampled interval, which would inform any acidizing programs.

Reduction of appraisal well drilling days

Drilling phase rig operating time

Drill bit run

The customer met all its formation evaluation goals and confirmed the reservoir quality and deliverability. It also confirmed the lithium concentration in the brine and the reservoir pressure. This information determined the stimulation program, completion tools, and well trajectories. The log data, good core recovery, testing, and analysis allowed the customer to move forward from pilot wells to field development.

The collaboration between Halliburton and the customer reduced the drilling days for standard appraisal wells by 24.8%, from 21 days to 15.8 days. The improved drill bit design and performance from the integrated drilling roadmap enabled drilling the main 8-½ in. section in a single bit run.

Create smaller mining footprints, reduce operational costs, and improve operational efficiency with Halliburton DLE technology and services.

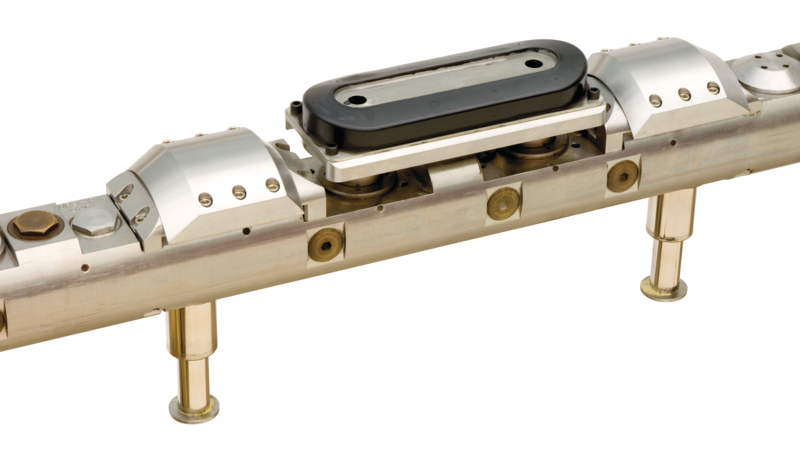

When flexibility and versatility are required, the Reservoir Description Tool collects —in a single deployment—formation pressure, fluid ID, and samples.

Examine the smallest pores and characterize formations using high-resolution, best-in-class magnetic resonance logging.

Obtain formation pressures and fluid samples in tough environments