Search

Search

Search

Search

Wellbore cleanout spacers cut filtration time, saving operator approximately $150,000

Download PDFDeep Water

Effective wellbore cleanout system and displacement program

Gulf of Mexico

A previous displacement performed by a competitor on a nearby well was unsuccessful because the wellbore cleanout process failed. The completion brine was ruined and had to be replaced. The operator challenged the Baroid team to provide a reliable and effective wellbore cleanout system and displacement program for the next well. The water depth was 5,346 feet (1,630 meters), and the well had a maximum deviation of 27°. Total depth was 27,249 feet (8,306 meters) in true vertical depth – 28,475 feet (8,679 meters) in measured depth. The well contained 3,256 bbl of 14.5-ppg synthetic-based fluid prior to the displacement.

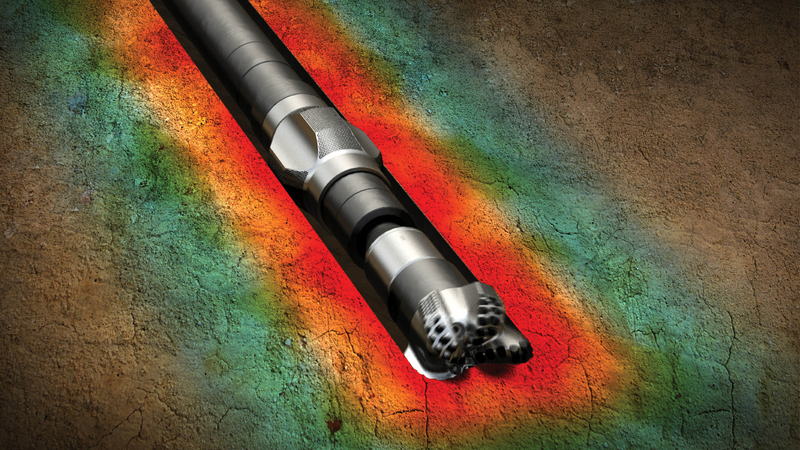

Lab testing showed that conventional products would not provide adequate cleanup of the drilling fluid system. Significant time and effort were devoted to developing spacer formulations that would efficiently remove and clean the drilling fluid from the wellbore. The optimal formulation contained BaraKlean®-648 casing cleaner.

BaraKlean-648 casing cleaner is a blend of surfactants and solvents that provide strong cleaning and wetting actions to break and disperse mud film and residue. Test results indicated that this product would provide superior cleaning efficiency.

When applied in the field, initial brine returns exhibited low NTU readings and negligible solids content, validating the cleaning spacer’s effectiveness. When the riser brush and magnet were evaluated during the short trip, they appeared to be water-wet and free of all drilling fluid residue. The subsequent cleanup of completion fluid to meet operator specifications was completed in a circulation of 1.5 wellbore volumes. The initial clarity of the completion fluid allowed the filtration unit to pump at 25–30 bpm. Previous maximum filtration rates achieved by this operator were 15–20 bpm.

bbl of 14.5-ppg synthetic fluid prior to displacement

bpm max filtration rate with BaraKlean-648

hours saved due to rapid removal of drilling fluid

saved in rig time

This engineered cleanout system delivered rapid removal of drilling fluid and drilling fluid residue from the wellbore, saving 2–3 hours on the final circulation and approximately USD 150,000 in rig time. This was the first completion performed on this rig, and Baroid personnel provided the guidance to successfully execute the displacement. This engineered blend of surfactants and solvents reduced costs and resulted in a clean wellbore.

Halliburton completion fluids optimally prepare, repair, clean out, and complete the wellbore to maximize production.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.

Advanced wellbore cleaning with BaraKlean® well cleaners.