Search

Search

Search

Search

Operator saves $2.4 million by eliminating wireline run in high-cost offshore well

Download PDFObtain uncontaminated and representative formation fluid samples

North Sea

In this deepwater well drilled from a floater in 1,240 feet (378 meters) of water in the North Sea, the customer wanted to obtain uncontaminated and representative formation fluid samples from the Jurassic and Triassic reservoir rocks. This high-cost environment always makes time savings a priority. In this particular case, Sperry Drilling services was challenged to provide a fluid sampling solution that could be run as part of the drilling bottomhole assembly (BHA), including while drilling out the casing shoe, which typically can lead to stick-slip vibration and shocks. On top of these requirements, rough seas with waves up to 9 feet (3 meters) high made this operation particularly challenging.

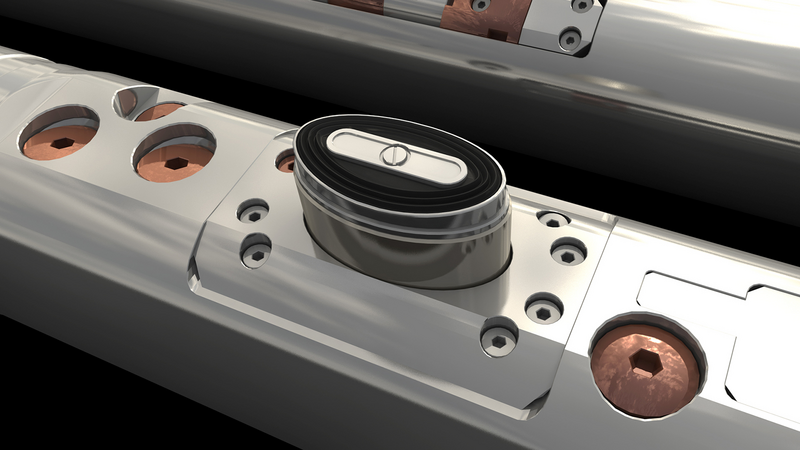

To achieve the primary objective of obtaining quality fluid samples while drilling, Sperry Drilling ran a Geo-Pilot® rotary steerable drilling system with a 6-¾-inch GeoTap® IDS fluid identification and sampling-while-drilling sensor.

An industry first, the GeoTap IDS sensor is easily positioned anywhere in the logging-while-drilling (LWD) BHA to provide fluid identification and allow multiple reservoir fluid samples to be rapidly recovered within hours of drilling the formation. This near-real-time sampling greatly shortens the amount of time the formation is exposed to drilling fluids, which in turn reduces formation damage as well as the resulting cleanup time required.

The Geo-Pilot system with GeoTap IDS sensor BHA drilled approximately 3,678 feet (1,121 meters) of 8-½-inch hole, including drilling out the shoe. In addition to taking multiple pressure tests, the GeoTap IDS sensor acquired two fluid samples during the interval drilled from 11,371 to 15,550 feet (3,466 to 4,587 meters), and another three samples on the way out of the hole.

Saved for the customer

Hours saved

Successful pressure tests

Sperry Drilling’s GeoTap IDS sensor enabled successful fluid sampling-while-drilling on this deepwater well, resulting in significant time and cost savings. Over a total of 108.3 actual hours, compared to the planned 149 hours, the GeoTap IDS sensor successfully retrieved five useful fluid samples along with 13 successful pressure tests, eliminating a wireline run and saving a total of four rig days while avoiding any nonproductive time (NPT) or health, safety and environment (HSE) incidents. At a rig cost of $600,000 per day, this outstanding performance saved the customer an estimated $2.4 million

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.

Fluid identification and sampling solution.

Direct formation pressure measurements on-demand.

Gather real-time, high-quality data while drilling for improved subsurface insight, increased ROP, and enhanced wellbore stability.