Search

Search

Search

Search

Innovative inflow pattern, extended length and coatings, reduced scale and debris, contributed to reduction in input power costs of over 15%

Download PDFScale buildup in geothermal operations can damage equipment and shorten runtimes

Germany

GeoESP intake provided:

Scale formation poses a significant challenge in geothermal electric submersible pump (ESP) operations. If extreme or left unaddressed, scale buildup can damage equipment and shorten run life. This issue is particularly critical for ESPs with up to 450-m³/h flow rates.

A German operator experienced three ESP failures due to scale buildup, resulting in runtimes of less than 60 days. The scale formed at the base of the bushing caused the systems to seize up, resulting in broken shafts.

As a result, the operator had to replace the damaged ESPs at a significant expense, which, for some operators, can reach up to €500k in pull expenses, equipment replacement, and downtime.

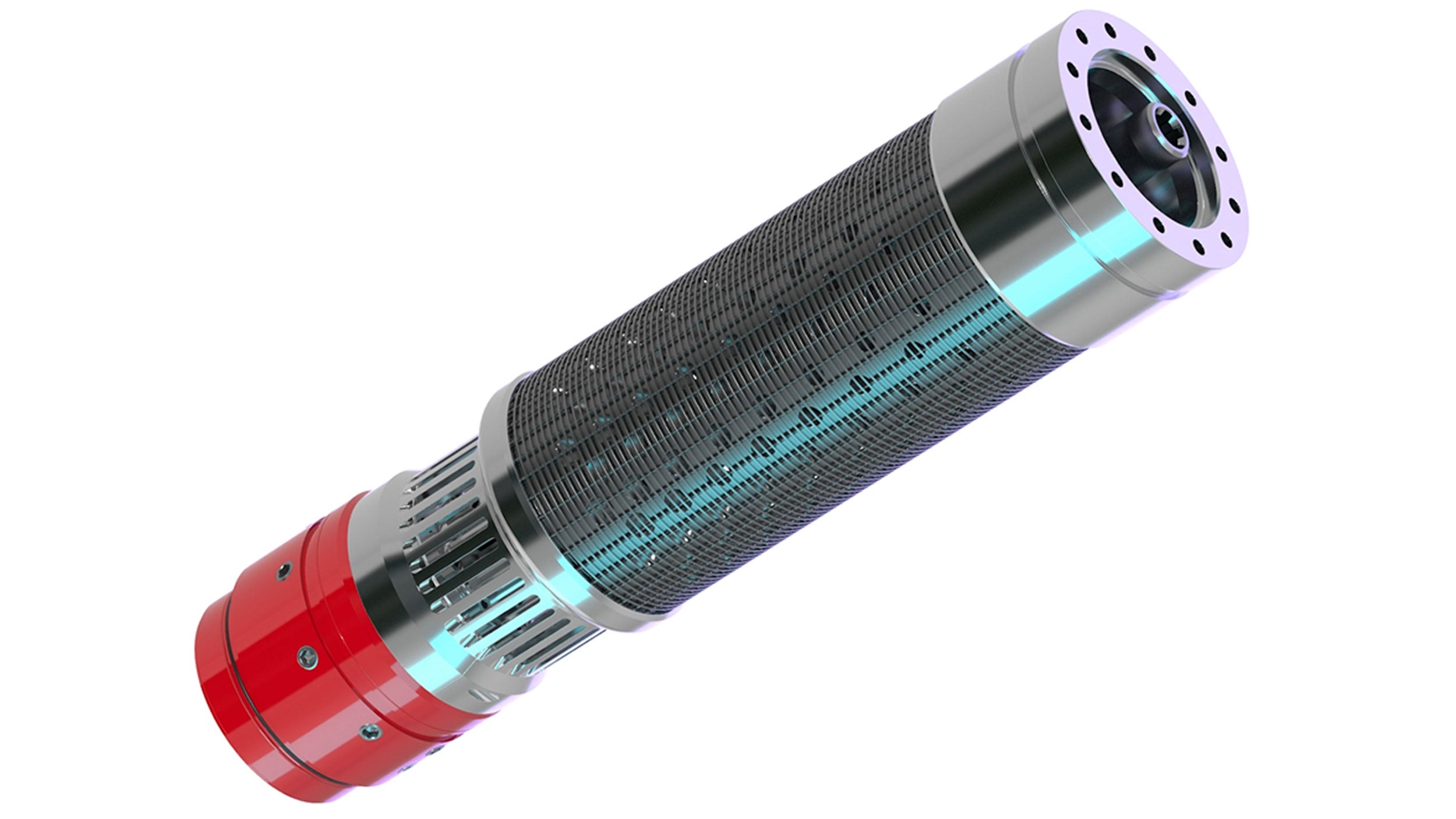

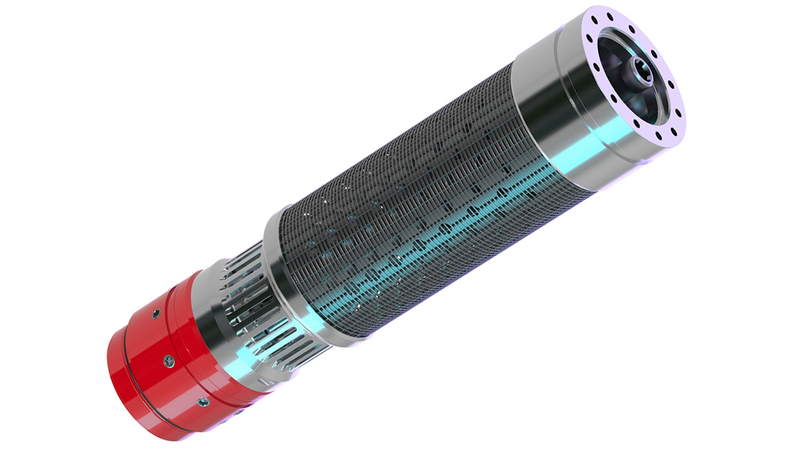

Based on historical experience and thorough analysis, Halliburton created an innovative GeoESP intake that significantly differs from traditional intakes used for decades.

Inspired by various industries, including medicine, engineers designed a solution to mitigate extreme pressure differentials around the intake, potentially reducing scale formation.

This solution not only protects against solids but also can reduce power consumption.

GeoESP Intake design features include:

Geothermal runtime

Increase in intake area reduced pressure differentials

Reduction in power consumption

Potential expense savings

Computational fluid dynamics (CFD) analysis reveals improved efficiency, with as much as a 70% reduction in pressure drop in some cases. This reduction can result in lower input power costs and a smaller carbon footprint. Monitoring through the Intelevate platform indicates an overall decrease in power consumption with the GeoESP® intake. When the team detected the initial signs of scale formation, the operator received notifications to implement mitigation techniques.

In a well with a 125 L/s flow rate target, 123° C fluid temperature, 570 m intake depth, and previous scale plugging issues that led to failure, the implemented GeoESP Intake tripled the run time and reduced power consumption by 18%. When considering the potential expenses operators may incur—up to €500,000 per well for workover and equipment costs, downtime, and possible cost efficiency gains—the GeoESP Intake proves itself a welcome innovation for geothermal operators.

Innovative, modular design seamlessly adapts to a diverse array of pumps and seals, delivering unparalleled solids protection in geothermal applications.

DuraHard coatings protect against friction, abrasive, and corrosive conditions, providing longer pump run life.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

The core of our digital ESP solutions integrates essential data sources and leverages advanced data science to automate workflows.