Search

Search

Search

Search

Advanced GeoESP system testing proves essential for evaluating a German geothermal plant's viability

Download PDFDeliver a comprehensive solution to confirm a geothermal project's feasibility

Germany

A customer was evaluating the viability of a new geothermal plant in Germany that would heat urban households and greenhouses. They required a complete solution, including surface equipment for easy deployment with a minimal footprint.

Due to uncertainty in reservoir characteristics and geothermal energy capacity, a versatile lifting solution was essential. Electric submersible pumps (ESPs) are the most effective for reservoir evaluation and managing high flow rates. They can also ensure effective testing of the project’s technical viability without complications or inaccuracies.

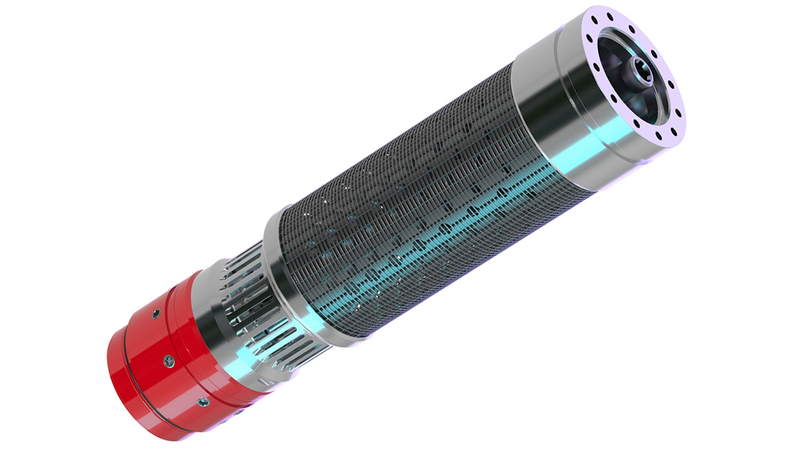

The Halliburton team provided a GeoESP Box Test Container 2000KVA surface well test unit, which offers a plug-and-play solution integrating PLCs, surface valves, and electric parameters and allows remote control of downhole equipment. For a complete reservoir evaluation, the 2100 hp GeoESP pumping downhole system has a wide production range of 80-120 l/s; coupled with the new GeoESP Intake, the potential for pump damage from scale and solids is minimized.

Powered by the Summit Knowledge™ digital ecosystem, the Intelevate® digital platform offers 24/7/365 remote monitoring, daily health check evaluations, and trend analysis recommendations. All necessary data covering well inflow performance, build-up, and pressure drawdown profiles is stored for mining authorities.

kVA Box Test Container successfully deployed

Horsepower GeoESP system installed

L/s production range

Remote monitoring and trend analysis recommended

This comprehensive solution enabled the operator to establish the geothermal project’s technical and economic feasibility, ensure safe operation across all required frequencies and flow rates, and preserve the GeoESP downhole system’s integrity for future use.

It also facilitated the testing of reservoir productivity and injectivity indexes to confirm production rates for electricity generation and characterization of geothermal fluid and aquifer hydraulic properties for surface plant sizing.

Ultimately, this solution provided a reliable and cost-effective means for the operator to determine the viability of their geothermal project, meeting both technical and regulatory requirements and investment budgets.

Halliburton's high-efficiency submersible borehole and surface pump technology for super-heated water and steam management in geothermal energy production.

Innovative, modular design seamlessly adapts to a diverse array of pumps and seals, delivering unparalleled solids protection in geothermal applications.

Simple, plug-and-play surface solution that feeds into our geothermal downhole pump when conducting well inflow performance tests.

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

The core of our digital ESP solutions integrates essential data sources and leverages advanced data science to automate workflows.