Search

Search

Search

Search

Summit ESP® reduced pump count and accelerated facility startup by six months

Download PDFRapidly deliver pumping solution for high-pressure water injection facility

Middle East

A customer required a high-pressure pumping system for a water injection facility with a short delivery timeline. The system needed to handle flow rates of 50,000 bpd at 5,300 psi. Traditional multi-stage API-610 pumps were not viable due to long lead times and limited flexibility. Halliburton’s Summit ESP® team delivered a horizontal pumping system (HPS) solution that met the pressure requirements, reduced complexity, and accelerated project delivery.

Water injection at extremely high pressures presents significant design and delivery challenges. Conventional multi-stage API-610 pumps offer limited operating range and flexibility, and their engineered-to-order nature results in lead times exceeding one year. To meet the pressure demands, a multi-pump HPS configuration, either in parallel or series, was required. However, such designs can be costly, complex, and difficult to install.

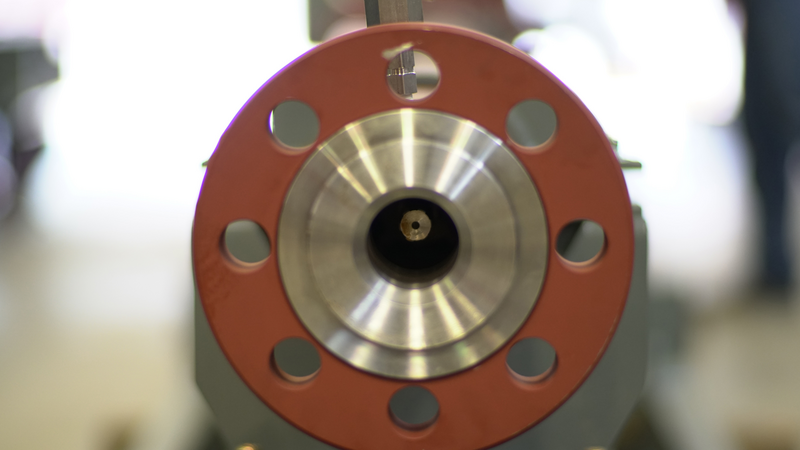

Summit ESP®, a Halliburton service, addressed the challenge with a design using four Hercules™ SH13500 pumps operating at 60 Hz (3,600 rpm). These pumps feature larger-than-standard shaft sizes, enabling them to handle high horsepower and pressure requirements. This design reduced the pump count from seven or eight units to four.

The pumps operated in parallel using a low-voltage variable-speed drive (VSD), which adjusted to a 60 Hz output despite a 50 Hz supply. This configuration allowed for faster delivery, simplified maintenance, and a shorter overall system length. Although the pumps remained long due to high discharge pressure, they were shorter than if sized for 50 Hz (3,000 rpm).

High-pressure, high-flow Hercules™ HPS

BPD total flow capacity

Delivery time

Capital expense reduction

The optimized solution reduced pump count and simplified installation. The customer benefited from streamlined pipework and controls, a shorter system footprint, and reduced infrastructure requirements. Estimated cost savings ranged from 25–50%. Most notably, the water injection facility became operational six months earlier than alternative solutions, enabling faster production and return on investment.

Hercules™ horizontal pumping systems (HPS) are an alternative to positive displacement, split-case, and other surface pumping options.