Search

Search

Search

Search

Successful deployment of ELH systems for subsea well

Download PDFDeep water

Complex wellbore environment

Indonesia

An international oil company has operated in Indonesia, specifically offshore, since 2001. A re-entry operation was scheduled for a well originally drilled in 2015. The goal was to sidetrack the well using a semi-submersible dynamic positioning rig at a water depth of 343 m. The re-entry operation would be performed in a complex well environment with a directional S-type drilling curve, featuring high inclinations of 70° in the 12.25 to 14-in. openhole (OH) section and a 54° inclination in the 8.5-in. OH sections.

This was the operator’s first campaign (second well) wherein VersaFlex® expandable liner hanger (ELH) technology was deployed rather than conventional liner hanger (CLH) technology. Despite the complex well environment, the VersaFlex ELH technology performed flawlessly and consistently met job requirements in this deepwater well environment.

The planning phases were broken into two distinct sections: Section 1: During the planning phase for the 10 3/4 × 13 5/8-in. long lateral section with a 12 1/2 to 14-in. OH section at 3710 m MD TD, a high run in hole (RIH) compression load needed to be addressed. A liner hanger system was deployed to a setting depth of 1090 m MD and a shoe depth of 3164 m MD, while high hang load capacity and swab and surge effects were effectively managed.

Section 2: In the second phase, the 7 × 10 3/4-in. section with 8.5-in. OH and 70° inclination at hanger depth, a liner hanger needed to pass through a tight tolerance. A surface rig issue caused continuous fluid losses and two days of static time without circulation during deployment.

Pressure integrity in the hanger was critical to support high-pressure pumping for the cased hole frac pack lower completion well design that was to follow the liner hanger installation.

In the long lateral section, tight spots increased the risk of premature liner hanger release during wash and ream operations. High fluid losses could also damage elastomers or cause setting issues. These potential risks could prevent deployment to depth or successful setting of the expandable liner hanger (ELH), both critical for achieving well integrity in the completion design.

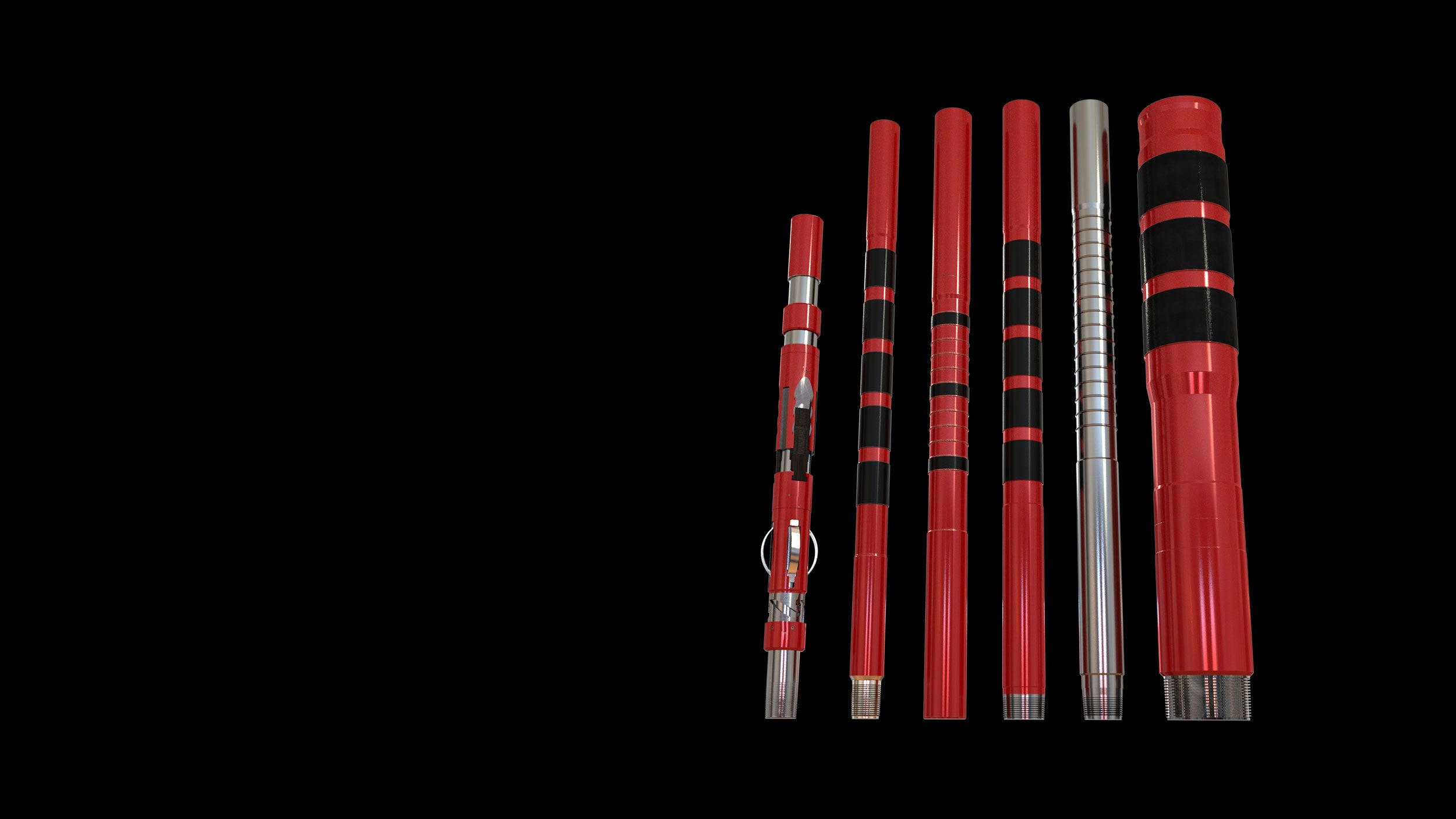

VersaFlex® ELHs were selected for this wellbore configuration in two system sizes: 10 3/4 × 13 5/8 in. and 7 × 10 3/4 in. Both systems feature a VersaFlex integral liner hanger/packer, which is made up of an integral tieback receptacle (TBR) above an expandable solid hanger body and a lower sleeve designed to withstand deployment-related tensile and torque loads. Elastomeric elements are bonded onto the hanger body and compress within the annular space upon expansion. This design virtually eliminates the liner hanger/casing annulus and provides liner-top pressure integrity while delivering impressive tensile and compressive load capability upon being set. With no moving parts, slips, or cages, the simple VersaFlex ELH system design helps eliminate the risk of premature setting.

The equipment was set with a SSR II™ casing wiper plug, SSR II landing collar, and Super Seal II® float collar and shoe. Deployment used a VersaFlex ELH running tool equipped with high-torque mandrels, J-Slot lockout device, and quick-lock collet to accommodate heavy hang weight and wash and ream capability.

Preplanning and design collaboration with all stakeholders addressed potential operational risks in advance. Competent field personnel executed the job without deviation from the approved wellsite instructions.

High-torque VersFlex® ELH deployed in Indonesia

Quick-lock VersaFlex® ELH deployed in Indonesia

HSE or SQ issues since deployment

Reached successfully

Halliburton successfully deployed both VersaFlex ELH systems to TD with zero health, safety, and environment (HSE) or service quality (SQ) issues. The system was set using a flapper mechanism, and the expansion process was clearly indicated. An overpull anchor test was performed effectively. Subsequently, the running tool was released as designed and successfully retrieved to the surface. The pressure test of the system demonstrated good liner top integrity.

The VersaFlex ELH design offers high reliability in scenarios with long liner lengths where challenges related to wash and ream capability and inadequate RIH compression load can cause CLH systems to fall short or set prematurely.