Search

Search

Search

Search

Average millout time proves to be 4.5 minutes, less than half of a typical composite plug

Download PDFUnconventionals

Find an easier-to-mill composite frac plug solution, scaling down time and risk

Williston Basin

An operator wanted to reduce the cost, time, and risk involved with milling out composite frac plugs

The operator was able to safely remove 90 plugs from two wellbores in less than 40 hours

An operator in the Williston Basin wanted to lessen the difficulty and duration of the post-fracturing treatment millout process. Fas Drill Ultra frac plugs were installed in two wellbores comprising 10,000-foot (3.048-meter) vertical and horizontal sections. The 4.5-inch frac plugs pumped down to their setting depths with exceptional efficiency and withstood the demands of stimulation.

After the fracturing treatment had been completed, both wells were milled out with a coiled-tubing unit. The Fas Drill Ultra plugs were quickly removed from the well with an average mill time of just 4.5 minutes. This saved the operator risk, several hours of operation, and tens of thousands of dollars in the overall cost of the completion.

The operator sought to scale down the time and risk required to remove composite plugs from the wellbore by using a coiled-tubing unit. With coiled tubing becoming scarce in the region, the operator has had to use a smaller 2-inch unit as opposed to the 2-3/8- inch unit that is conventionally used. Subsequently, the operator was looking for an easier-to-mill composite frac plug solution.

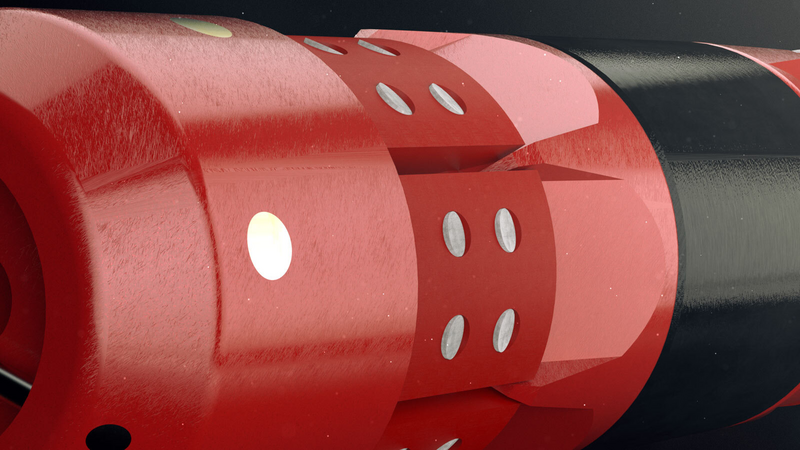

Halliburton recommended Fas Drill Ultra frac plugs. These plugs have optimized geometry for efficiency while pumping the wireline tool string to depth, thus reducing fluid consumption. Additionally, the Fas Drill Ultra plug is composed of easy-to-mill composite material. The design has been enhanced for millability without sacrificing fluid efficiency.

ft wellbores

minutes per plug average millout time

plugs removed from wellbores

of millout time saved

Fas Drill Ultra frac plugs were pumped to, and set at, the desired depths with an average volume efficiency of 51 percent without the use of a pump-down ring.

The operator was able to safely remove 90 plugs from two wellbores in less than 40 hours with an average mill time of 4.5 minutes per plug – less than half of the typical composite fracturing plug.

Greatly reducing the difficulty and duration of the coiled-tubing millout saved the operator tens of thousands of dollars in cost, along with days of operation. The operator is continuing to focus on efficiency and partnering with Halliburton for the best completion solutions.

Fas Dril Ultra frac plug

This high-performance frac plug is rated up to 10,000 psi for zonal isolation during wellbore stimulation and combines the Halliburton industry-leading frac plug design with the most advanced composite and rubber materials.

Download Data Sheet

Halliburton frac plugs isolate zones during stimulation, bringing production online faster