Search

Search

Search

Search

VersaFlex® XSL expandable liner hanger and Ball-Set running tool provide a pressure-balanced system for floated liner applications

Download PDFUnconventionals

Multiple difficulties associated with floating in the liner hanger

Permian Basin

Multiple difficulties associated with floating in the liner hanger using casing-conveyed buoyancy systems

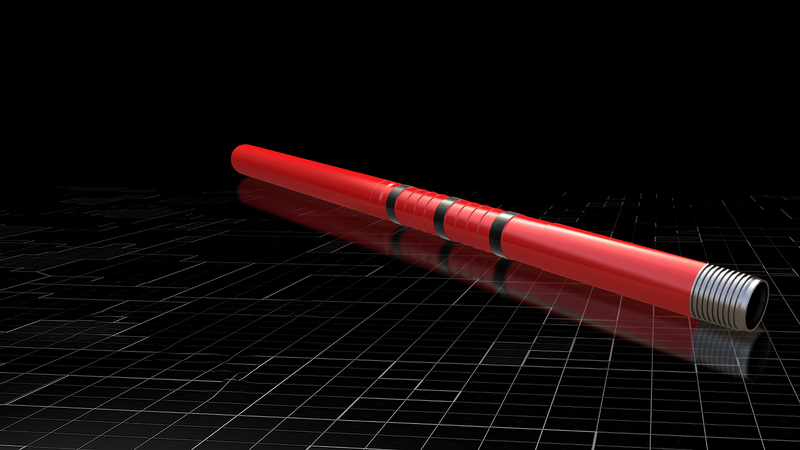

VersaFlex® XSL expandable liner hanger and Ball-Set

running tool

Successful float-in deployment with zero HSE or service quality issues

An operator in the Permian Basin wanted to optimize production liner deployments and required a 5.5 x 7.625-inch liner hanger system that could be floated in “mud over air” using a casing-conveyed buoyancy system. Such buoyancy systems are easily integrated with the casing string; however, certain challenges should be considered when incorporating these tools in a liner application.

Halliburton delivered a VersaFlex XSL expandable liner hanger and utilized the Ball-Set running tool to provide a pressure-balanced, engineered system tailored for floated liner applications.

To deploy a liner hanger system using the “float-in” method, a casing flotation sub is run as part of the liner string and serves as the temporary fluid barrier. When running in, the work string section above the flotation sub is fluid filled while the liner section below remains unfilled. This creates the buoyancy effect that reduces drag forces. Once the liner system reaches target depth (TD), the flotation sub must be ruptured to re-establish circulation and continue cementing operations. High surface pressures applied during the rupturing process can cause hydraulic imbalance in the work string as the fluid/air swap occurs and increase the risk of premature hanger setting and/or premature running tool release.

The VersaFlex XSL expandable liner hanger and Ball-Set running tool provided a reliable solution for this application because the system remains fully pressure balanced and unaffected during the hydraulic events associated with the flotation sub rupturing process.

The expansion pistons of the Ball-Set running tool remain equalized until a setting ball is dropped into the running tool string. When the setting ball lands on seat, an internal sleeve shifts, which routes pressure to the piston and allows for expansion.

HSE issues

SQ issues

efficiency and maximized asset value

Halliburton deployed the floated liner system to TD successfully with zero health, safety and environment (HSE) or service quality issues. After the casing flotation sub ruptured, the air section in the liner filled with fluid as designed. Subsequent cementing operations resulted in an accurate plug bump followed by liner expansion.

The VersaFlex XSL liner hanger with Ball-Set running tool provided a pressure-balanced system ideal for floated liner applications, which helped improve deployment efficiency and maximize asset value.

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications