Search

Search

Search

Search

Mud-pulse telemetry service helps operator achieve 100% operating efficiency

Download PDFUnconventionals

Revise the current MWD system to improve performance and operating efficiency

Montney Formation, Canada

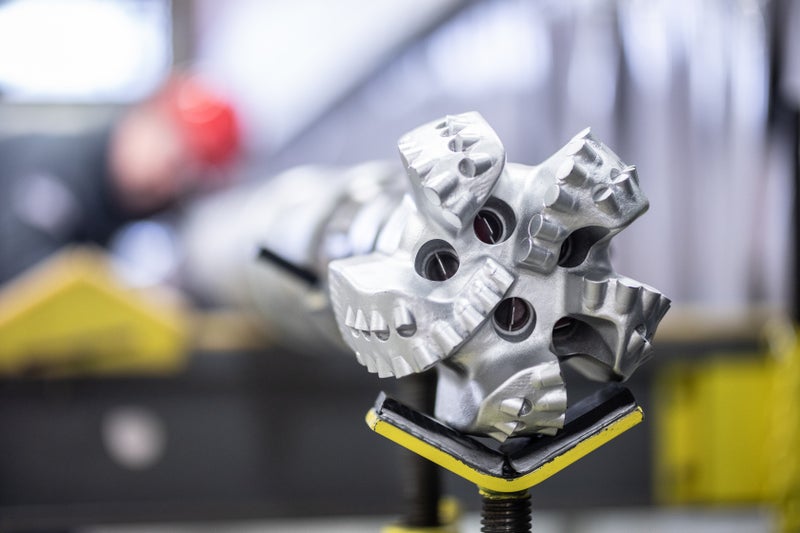

An operator drilling in the Montney Formation was experiencing technical challenges while drilling 156-mm production well sections. Recently, there had been an increase in mechanical damage to the mud-pulse telemetry components of the measurement-while-drilling (MWD) system, resulting in unplanned trips.

The Halliburton Sperry Drilling team collaborated closely with the operator to conduct an investigation and develop an engineered solution to the problem. Due to the rheological properties of traditional brine drilling fluids, there was minimal dampening effect between the MWD system and the collar interior diameter (ID), causing cross-axial vibrations. While drilling with a fluid of near Newtonian rheological properties, flow rates through tight IDs of internal bottomhole assembly (BHA) components become violent. This can lead to vibrations that are independent of the drilling operation and detrimental to performance.

The engineered drilling solution included new inspection equipment, rework procedures to the collar ID, and specialized coatings added to the flow section of the MWD system. These engineering control changes reduced the internal cross axial vibrations and optimized operating efficiency to 100%, reduced well time with the upgraded MWD system.

operating efficiency

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

MWD solutions are engineered to reduce well time and maximize reservoir contact from unconventional resources to extended-reach environments.