Search

Search

Search

Search

Endurance Hydraulic Screen® systems reduce overall completion time in environment with continuous reservoir pressure depletion

Download PDFMature Fields

Complex, costly OHGP required alternative

Norway

An operator offshore Norway deployed Endurance Hydraulic Screen® systems (EHS systems) to help provide wellbore support, overcome challenges, and support effective downhole sand control. The technology was selected for its notable installation simplicity, flexibility, and life-of-well reliability

The operator faced sand control issues in a reservoir characterized by low operational margins and continuous reservoir pressure depletion. Openhole gravel packing (OHGP) in this environment can be complex and expensive, so an alternative was necessary.

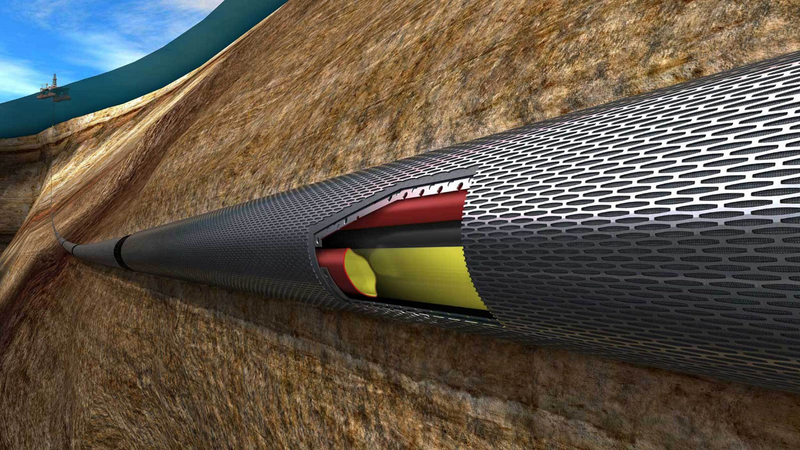

To achieve flow performance in openhole sand control completions, the annular gap between the screen section and wellbore must often be eliminated.

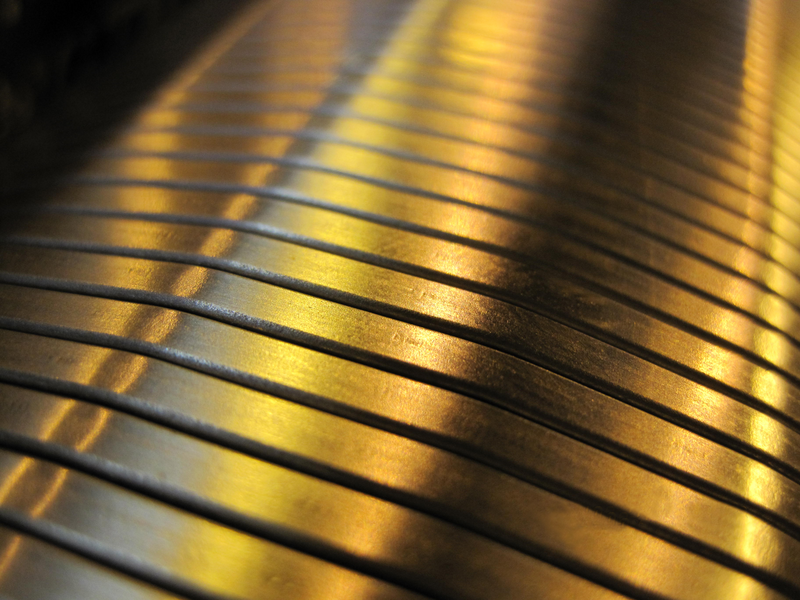

Halliburton recommended deployment of EHS systems in the 6-in. and 8.5-in. openhole reservoirs. The operator selected this technology for its installation simplicity, flexibility, and strong wellbore support, which can reduce costs and help mitigate service quality (SQ) and health, safety, and environmental (HSE) risks.

The EHS systems were integrated with standard equipment, which included a fluid-loss isolation barrier and a simplified fluid strategy. Hydraulic activation pressure radially extends the screens to conform to the borehole geometry in a fast, safe, and reliable manner. This proven technology supports major operational efficiencies using a single-trip installation process. The system uses standard tubular base pipe in both solid and predrilled base pipe versions; in this case, a solid base pipe was used.

By eliminating the annular gap, the Endurance Hydraulic Screen® EHS system delivers a positive, compliant sand control solution that improves wellbore support and reduces risks associated with traditional methods. It significantly reduces operational challenges typically linked to mechanically expanded screens and gravel-packing operations.

system selected as primary solution

reduction in overall rig time

significant savings realized with logistic risks

With two service specialists at the wellsite, once the completion reached target depth, the hanger was set and EHS joints were activated within an hour.

This contributed to a new record completion time for the field. The operator achieved significant savings in operational planning, logistics, HSE risks, and rig time. With production-rate expectations met, the operator selected the EHS system as the primary solution for late-life field development.

Design and select optimum chemicals, fluid-loss control systems, and completion tools for each well

Whatever the challenge, Halliburton experts stand ready with solutions using the most effective, reliable, value-added sand control screen technology in the business