Search

Search

Search

Search

New pipe-cutting solution helps achieve required P&A, eliminating the need for fishing

Download PDFDeep Water

Clear obstruction to successfully deploy cutter to target depth

North Sea, UK

An operator in the North Sea sector was working on the last well of a continuous five-well plug and abandonment (P&A) campaign. Pipe severance was the final stage of the operation. Because of wellbore restrictions, most likely debris, the operator couldn’t reach the target depth to cut the tubing with their planned method. They approached Halliburton to provide a tubing-cutting solution that could be mobilized quickly to the wellsite. Halliburton recommended using its new electromechanical cutter that is extremely effective in addressing restricted inside diameter (ID) cutting operations. The successful solution potentially saved the customer days of attempts to clear the obstruction and eliminated the need for any fishing operations.

In this final well, the operator had been unable to reach the required depth to cut a 5½-in. L-80 tubing for P&A of the producing zone. There had previously been a cement plug bullheaded to the reservoir, which had resulted in cement stringers up the well. This had broken up in part causing debris to accumulate in the tubing, reducing the ID and preventing the planned explosive cutter from being deployed. Since the offshore rig was waiting, rapid logistical deployment and operational readiness were required to mobilize efficiently and effectively.

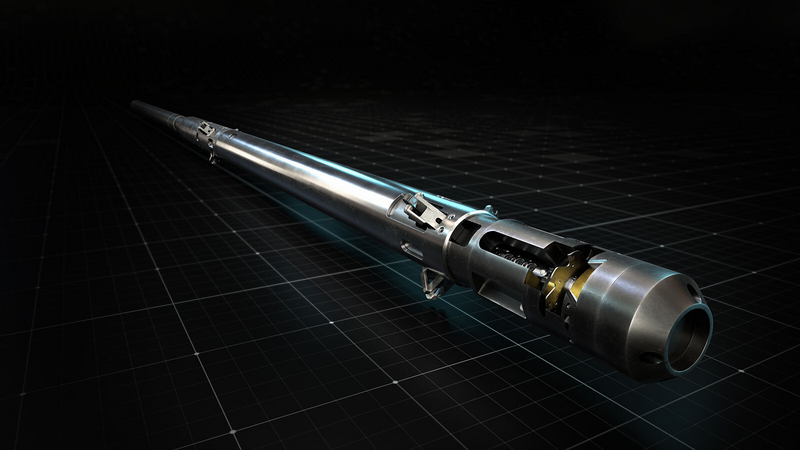

Halliburton proposed a 2¾-in. singleblade electromechanical cutter with a 3-in. outside diameter (OD) head that would enable going through the restricted ID while still allowing the target tubing to be cut successfully. The highly efficient cutting mechanism typically cuts 5½-in. tubing in less than two minutes from point of contact. Using this technology, successful wireline interventions are performed in a single run. Real-time data gives immediate notification of cutting progress and success, and eliminates operational uncertainty. Cutting-tool accuracy also ensures only the pipe is cut, with no damage to the outer casing or control lines. Additionally, radio silence, explosives, and chemicals are completely eliminated, minimizing the HSE risk associated with more traditional cutting methods.

feet target depth (TD)

The Halliburton electromechanical cutter was deployed within hours of the operator being unable to reach TD. The rapid mobilization enabled the mechanical cutter and specialist to be on the rig within hours of discussing a need for this solution. A slickline crew at the wellsite deployed multiple drifting/gauging and bailing runs to prepare the well for the electromechanical cutter deployment. E-line was used to deploy the electromechanical cutter successfully to target depth. A Halliburton specialist demonstrated to the on-site customer rep the different phases of cutting through the debris and then through the tubing. A final positive indication of pipe cut was available within minutes using the electromechanical cutter’s surface-readout control panel. A precisely located, machine shop-like-quality tubing cut was successfully retrieved to surface. With the electromechanical cutter deployment, the customer potentially saved days of attempts to clear the obstruction and removed the need for any fishing operations.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.