Search

Search

Search

Search

Halliburton customized a unique completion solution for multi-zone interventionless stimulation

Download PDFMature Fields

Needed to achieve a multi-zone interventionless stimulation

South Texas

A major operator in South Texas was looking for the most cost-effective way to achieve a multi-zone interventionless stimulation in an Eagle Ford shale reservoir, while effectively compartmentalizing the intervals.

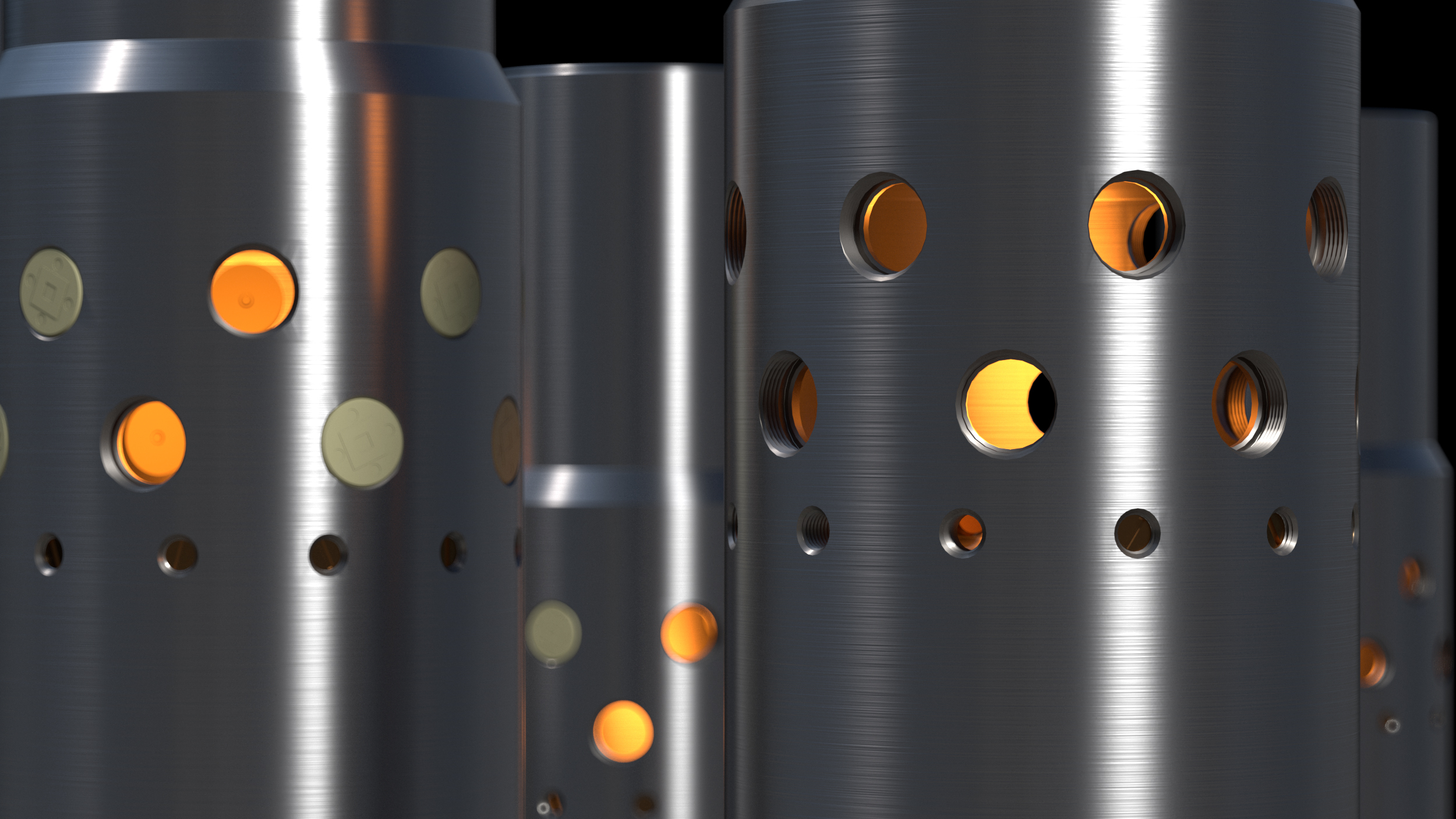

Due to the challenging well conditions, Halliburton customized a unique solution that included RapidStage frac sleeves, a VersaFlex expandable liner hanger, and Swellpacker® oil-swelling (OS) high-temperature (HT) packers.

After successfully reaming the wellbore, the completion assembly was run to total depth in less than 18 hours without incident. In addition to running the assembly so quickly, the operator was able to continue 24-hour pumping operations and interventionlessly stimulate multiple zones in less than two days. Compared to previous wells in the field, Halliburton saved the operator $1 million on this well.

Running completion equipment into the well was a major concern of the operator’s, as a result of past performance issues that had included trouble getting to depth due to hole geometry and inadequate reaming procedures. The operator was also concerned with high-temperature conditions as well as possible hydrogen sulfide (H2S) influx, and needed reliable equipment that could withstand these harsh conditions. Completion design and well performance were both critical points in making this shale play economical for the customer.

The Halliburton South Texas team performed an extensive well analysis and evaluation in order to design the most optimal simulation and completion design for the challenging well conditions. Torque and drag analysis was conducted to ensure that the entire assembly could run to bottom efficiently. To help ensure the design met the operator’s expectations and requirements — including the completion system being able to handle all wellbore fluids — extensive simulations were performed to model different Swellpacker isolation systems.

Based on the torque and drag analysis, a stiffer, more robust reaming assembly was proposed that would help better replicate the completion assembly. While following best practices for well reaming, Halliburton also created a unique solution for the assembly, to help make the process more successful. The Halliburton reaming/drift assembly was enlarged to be the same length as the Swellpacker isolation system. Three multi-zonal completion/stimulation methods were tested in the field to determine which completion system was the most cost-effective without compromising value and results. The tests led the Halliburton team to recommend the RapidStage completion service, which included the following components:

completion assembly was run to total depth

days to stimulate multiple zones

million saved on this well, compared locally

After successfully reaming the wellbore, the completion assembly was run to total depth in less than 18 hours without incident. In addition to running the assembly so quickly, the operator was able to continue 24-hour pumping operations and interventionlessly stimulate multiple zones in less than two days.

Using the pneumatic ball dropping head, all RapidStage sleeves were opened while continuously pumping, allowing each stimulation treatment to be accurately placed. The use of Swellpacker isolation systems as the primary isolation method reduced treating pressure versus previous exploratory wells drilled.

Compared to previous wells in the field, Halliburton saved the operator $1 million on this well.