Search

Search

Search

Search

CorrosaCem™ cement system provides corrosion resistance and achieves zonal isolation

Download PDFCCUS well

Corrosion-resistant cement solution for future planned CCUS wells

Japan

Carbon capture, utilization, and storage (CCUS) has become a primary means used to help prevent carbon dioxide emissions into the atmosphere. Wells used for CO2 storage require a rigorous design process to meet local regulations and long-term integrity requirements. One of the key requirements for long-term integrity is full annular isolation of the production casing with CO2 corrosion-resistant cement.

An operator in Japan planned to drill a CCUS well into a depleted reservoir and inject CO2 emitted from hydrogen and ammonia production nearby. The corrosive environment required corrosion-resistant cement across the zone of interest to maintain well integrity, as conventional Portland cement can degrade over time when exposed to CO2. Cyclic injection in CCUS wells further increases the risk of mechanical failures, such as cement debonding.

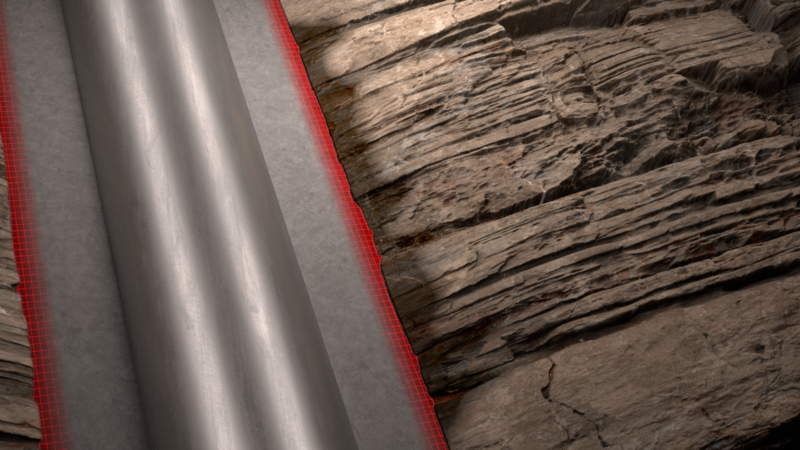

In addition, these wells are in a low-fracture-gradient area, which makes it difficult to lift high-density cement to the planned top of cement (TOC) without exceeding equivalent circulating density (ECD) limits. Regulations mandate a cement bond log (CBL) in the injection section to confirm proper cement isolation.

The CorrosaCem™ cement system, a corrosion-resistant, reduced-Portland cement solution, was deployed in the injection zones. CorrosaCem cement system replaces a portion of Portland cement with supplementary cementitious materials (SCM) that do not react with CO2. This helps improve CO2 corrosion resistance. The solution was tailored with IsoGuard® fluid additive to reduce permeability, which further enhances corrosion resistance and improves shear bond to mitigate the risk of debonding caused by cyclic loading. The cement system was designed at relatively low density, 1.25-SG lead and 1.50-SG tail cement, to help minimize ECD.

SG lead cement

SG tail cement

Confirmed isolation

A total of 27 bbl of 1.25-SG CorrosaCem system lead cement and 27 bbl of 1.50-SG CorrosaCem system tail cement were mixed and placed in the 9 5/8-in. intermediate string and 7-in. string. A CBL confirmed cement coverage throughout the wellbore, which helped the operator to apply for their CCUS well application.

Tailored to improve chemical resistance to CO₂ and enhanced mechanical properties that minimize the impact of cyclic loading on the cement barrier integrity.

IsoGuard™ cement additive mitigates annular flow through unset cement by providing excellent fluid loss control and shortening transition time.