Search

Search

Search

Search

RockStrong™coring system with telescopic inner assembly (TIA) optimizes offshore CCUS project in Australia

Download PDFSustainable Energy

Operator needed coring strategy for offshore CCUS project in Australia

Australia

An operator consulted Halliburton to recommend a coring strategy for an offshore carbon capture, utilization, and storage (CCUS) project in Australia. The recommendation included using the RockStrong™ coring system with a Telescopic Inner Assembly (TIA). The core samples, preserved using various methods, varied in lithology and unconfined compressive strength (UCS). This strategy met all core objectives and evaluated the CCUS potential of the wells.

The project required core samples for field evaluation. With no core samples from offset wells, Halliburton used its extensive coring experience to meet the operator's objectives. A conventional coring program of six intervals that totaled more than 400 m was identified for CCUS exploration and appraisal in two wells. This was central to the formation evaluation program, which is foundational for development.

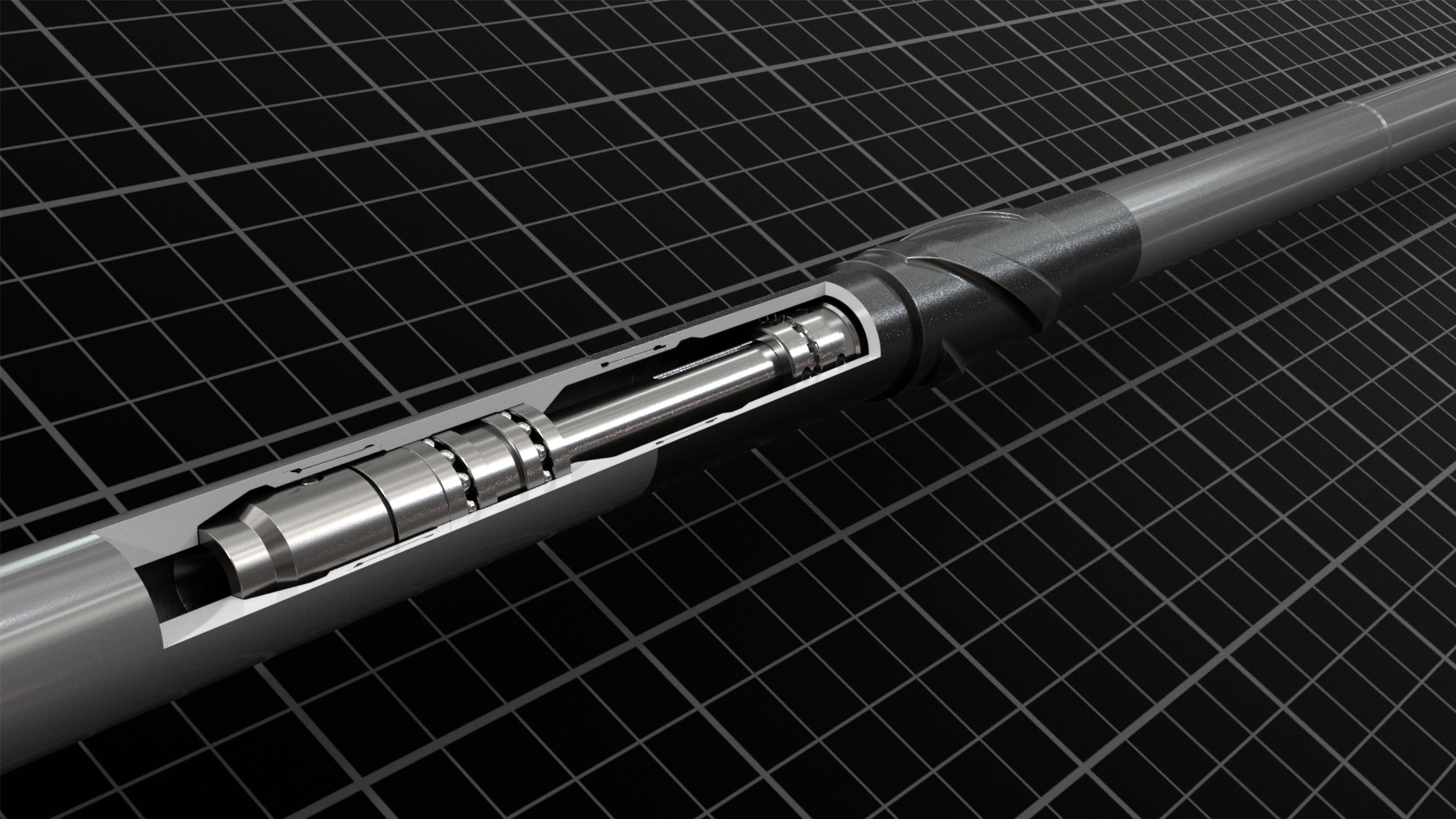

Halliburton recommended the swivel assembly RockStrong™ coring system with a Telescopic Inner Assembly (TIA). This jam mitigation system maximizes core efficiency with a long coring bottomhole assembly (BHA) through interbedded formations. Halliburton uses a unique modeling program to understand BHA behaviors for varying barrel lengths and drillstring dynamics. This helps facilitate optimal coring performance under any conditions. An 8 1/2-in. corehead was designed for performance, efficiency, and durability.

Recovered core

Core runs

Core recovery

The operator completed 12 core runs with this configuration, recovering 413.82 m of core at a 95% recovery rate. The core was in good condition and preserved safely at the rig site. Core samples varied in lithology and unconfined compressive strength (UCS), requiring preservation methods such as mineral oil, PVC shims, foam stabilization, and dry ice. A total of 10 TIA activations allowed additional core capture compared to a conventional system, reducing BHA trips and significantly saving costs.

All core acquisition objectives were achieved, enabling the operator to study rock properties and evaluate the CCUS potential of these wells.