Search

Search

Search

Search

RockStrong FCS™ coring system combined with RockSight™ split liner coring system results in a 98.5% core recovery rate.

Download PDFUnconventionals

Provide quick access to core at the surface to aid analysis for CCUS

Japan

An operator desired quick access to core samples from the surface to evaluate a field for carbon capture utilization and storage (CCUS) potential. Halliburton was recruited to recover 45 m of core from the 8 -1/2 in. target formation comprised of hard caprock (up to 40 kpsi unconfined compressive strength) in the top section and unconsolidated sand (5 to 10 kpsi unconfined compressive strength) in the lower section. Coring was planned just below the casing shoe with high potential for junk/debris. Uncertainty involving formation hardness required a secondary core catcher system.

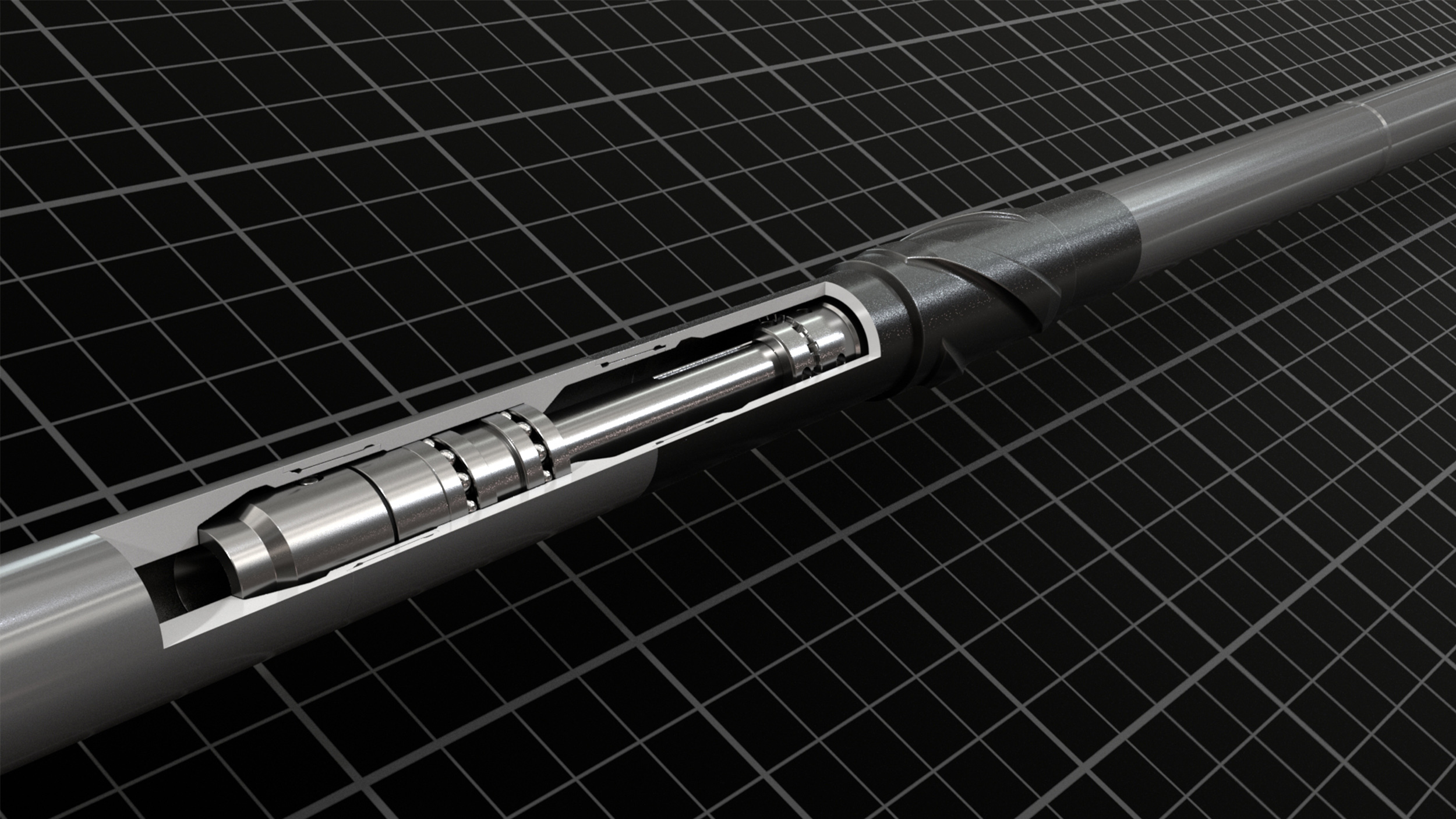

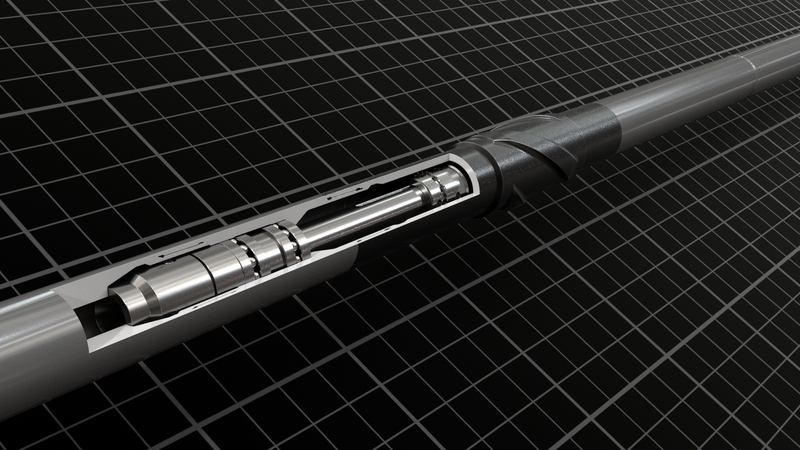

To help mitigate vibration in the interbedded top section and capture core where the formation hardness was uncertain, Halliburton deployed the RockStrong FCS™ coring system. Because minimizing vibration is crucial to reducing core jamming, the RockStrong FCS jamming mitigation design includes a top spacer assembly that acts like a preloaded spring to absorb axial vibration along the inner assembly. The double bearing on the shaft keeps the inner barrel in a stable and vibration-free position to facilitate smooth core entry, helping maximize recovery in the unconsolidated formation.

For quick core access from the surface, this technology was combined with the RockSight™ split liner coring system. Because of the dual lithology of the formation and based on offset well performance, an optimized FC3843 coring bit was selected for optimal performance. This was Halliburton’s first time deploying this technology combination in one job.

A total of 45.3 m of good quality 4 in. core was recovered for analysis purposes with a 98.5% recovery rate using the RockStrong FCS system. The RockSight system allowed the geologist to gain access to the core safely and efficiently from the surface.

Meters of good quality 4" core

Recovery rate

The RockStrong™ coring and anti-jamming system was designed for maximum reliability under the harshest conditions.