Search

Search

Search

Search

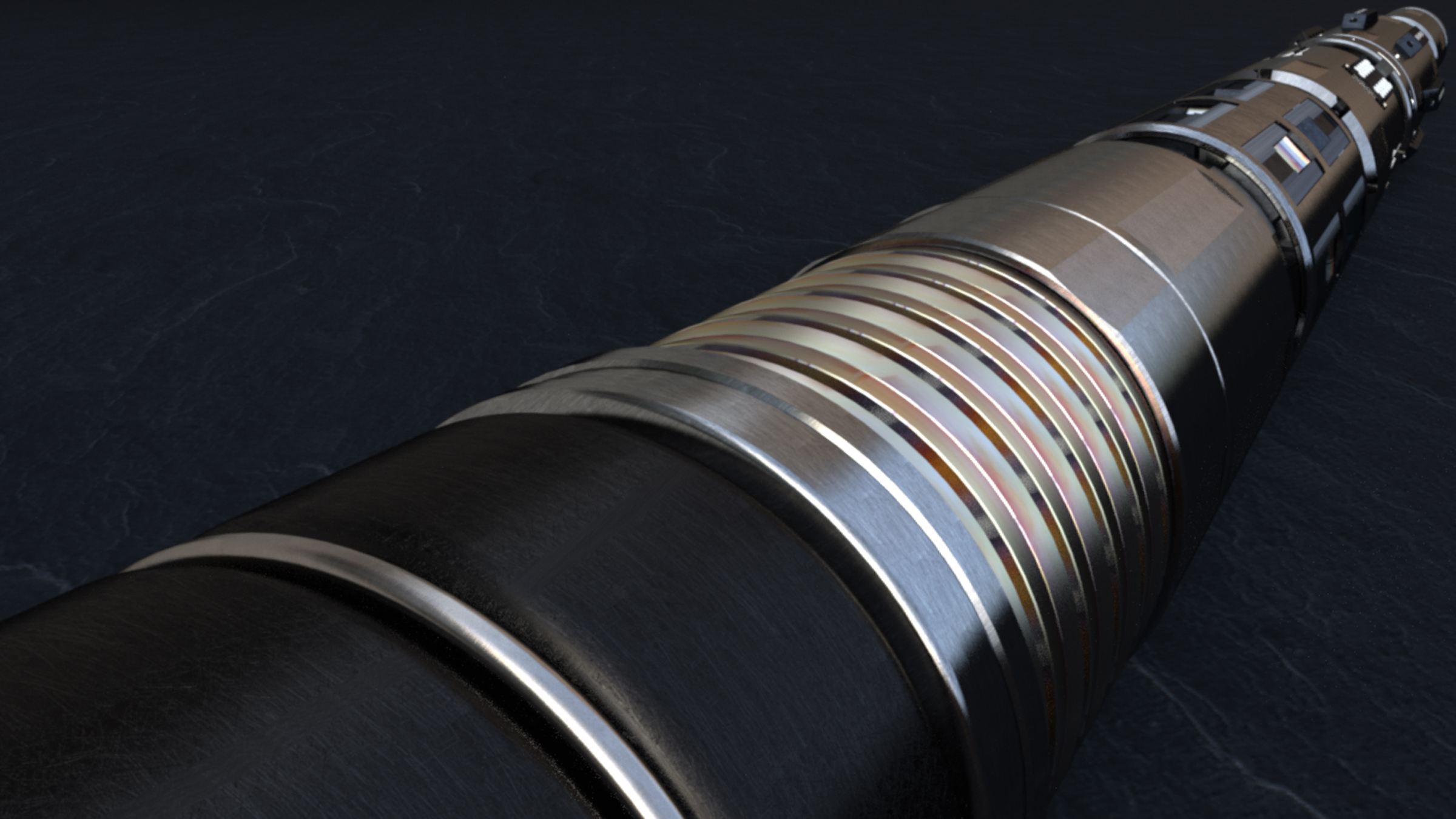

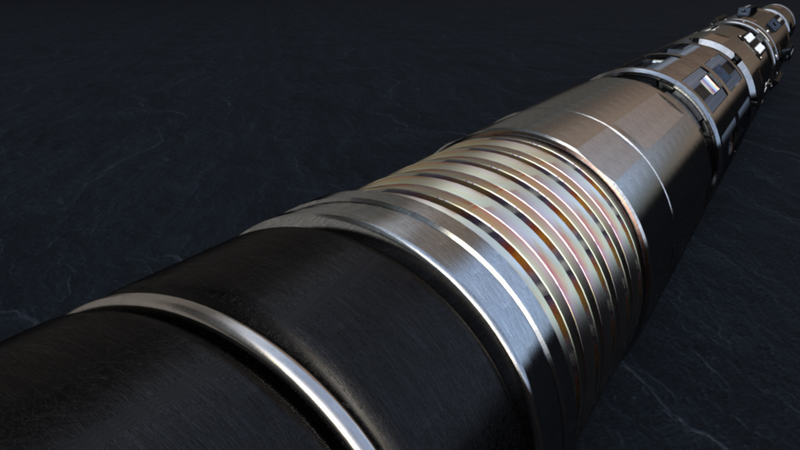

Intercept® retrievable bridge plug and Turbo Tech® II tool combined for success

Download PDFMature Fields

Safely manage gas present below the RBP using correct control measures

North Sea

Our customer wanted a reliable and simple solution to address any potential pressure/gas buildup below a retrievable bridge plug (RBP) set as a temporary barrier in plug and abandonment (P&A) and horizontal tree (HXT) operations.

It is advantageous to address the buildup of any pressures from the annulus side vs. the drillpipe prior to unsetting the RBP.

Halliburton proposed a combination of field-proven technologies and successfully completed the project with ZERO non-productive time (NPT) or cost of poor quality (COPQ) incidents.

During temporary P&A and HXT operations, the customer utilized an Intercept® RBP as a temporary barrier. Due to potential trapped pressure/gas buildup below the plug, the customer asked Halliburton to provide a dependable resolution that allows operations to effectively manage such buildup prior to unsetting the plug.

To meet the operational objectives, Halliburton proposed incorporating the field-proven Turbo Tech® II multi-activation bypass valve in the Intercept API 11D1 V0-rated RBP retrieving string. This combination allowed Halliburton to assess the pressure below the plug, bleed off this pressure at surface via the annulus and safely and efficiently manage operations while the V0 barrier remained in place for well control.

non productive time

cost of poor quality incidents

Halliburton performed the job with ZERO NPT or COPQ issues. The successful execution of this operation demonstrates that the integration of field-proven technologies can deliver innovative and safe solutions to maximize asset value for our customers. It also highlights how collaboration can foster fresh ideas within our business.

Gas-tight, well-suspension plug ideal for dual-barrier applications and designed to handle a wide range of well conditions, helping you maximize well control.