Search

Search

Search

Search

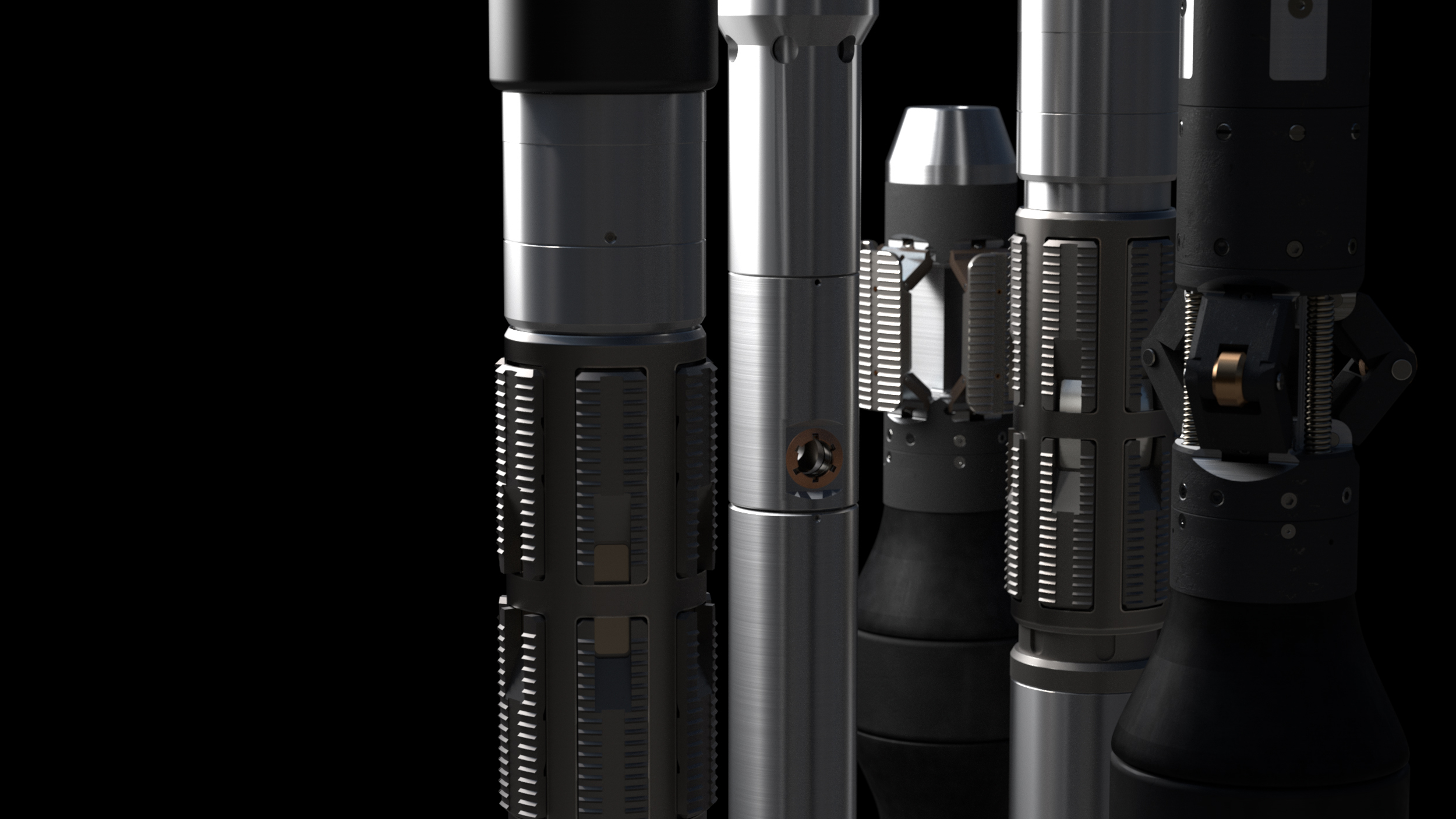

Evo-Trieve® retrievable bridge plugs with real-time monitoring technology enable barrier verification in a single run with zero NPT

Download PDFMature Fields

Secure well for Christmas tree maintenance

Norway

A major operator needed to secure an offshore well and perform a valve changeout on the Christmas tree. To establish the required barriers and help ensure safe and effective operations, Halliburton collaborated with a local service company to provide a combined technology solution.

The operator planned to install two shallow-set barrier plugs above the downhole safety valve (DHSV) using slickline and conventional timer-based setting tools. However, because the plugs would be set close together, conventional volume control could not accurately deliver a good barrier leak test. The optimum method to ensure a proven barrier required monitoring of the small volume between the installed bridge plugs during leak testing.

Halliburton recognized an opportunity for collaboration with a local service company to deliver a reliable solution that combined field-proven Evo-Trieve® bridge plugs with real-time barrier integrity monitoring. During this first-time collaboration, the companies developed a concise up-front system integration test (SIT) program to operator- specific requirements, which ultimately led to successful downhole operations.

A real-time monitoring device mounted on the shallow Evo-Trieve retrievable bridge plug enabled wireless live monitoring at surface through the Christmas tree. In addition, a slickline wireline adapter with memory module was included in the bottomhole assembly to provide secondary data collection and storage.

The first Evo-Trieve retrievable bridge plug was set using the DPU® downhole electrical power generator at 649 feet (198 meters) measured depth (MD) and inflow tested from below and leak tested from above at 290 and 3,916 psi (20 and 270 bar). The shallow Evo-Trieve retrievable bridge plug was set at 183 feet (55.7 meters) MD and leak tested from above at 290 and 3,916 psi (20 and 270 bar).

During leak testing of the shallow barrier, the real-time monitoring device continuously transmitted pressure and temperature (P/T) data from above and below the barrier to surface, and the signals picked up by the surface logging system. Additionally, the device allowed the operator to send commands directly to the real-time monitoring device and “prompt” for additional P/T data throughout the pre-programmed transmission sets.

delivered high levels of accuracy

to enable barrier verification

for leak testing completion

The Evo-Trieve retrievable bridge plug with real-time monitoring device performed at a high level of accuracy and provided proven barriers for the subsequent maintenance operations. The collaborative approach maximized the operator’s asset value, delivering reliable, efficient, cost-effective and safer operations.

Utilizing Halliburton integrated operations reduced the need for dedicated intervention personnel on site, and the entire system was deployed in a single trip. In addition, slickline operations provided additional time savings during rig up, testing and deployment compared to typical electric line operations.

P/T data transmitted in real time enabled quick decision-making and allowed the operator to act according to the test results. Data from the memory module was downloaded and included in the final report to the operator.

Evo-Trieve® and Evo-Trieve HP Bridge Plugs

Customizable intervention solutions for wellbore remediation reduce well time and costs.