Search

Search

Search

Search

Turbo Tech® II valve and Inflow Tech® packer with SCM increase new technology footprint in Southeast Asia

Download PDFMature Fields

Perform single-trip wellbore cleanout and negative test on the liner

SE Asia

A major operator in Southeast Asia faced a complex wellbore cleanout requirement with no previous run history at the location. To achieve customer objectives, the operator required a string design that allowed for a negative test, cleanup, and displacement all in a single trip. After collaborating with the global team, Halliburton identified a field-proven, reliable solution from the CleanWell® portfolio of tools. This integrated solution enabled a negative test of the liner top, full displacement from drilling to completion fluid, and high-rate circulation and filtration to the required specification, without dropping activation balls or darts and all within a single trip.

Meeting the customer’s objectives for the wellbore cleanout and well displacement phase proved challenging. Specifically, the operator required a single-trip operation to achieve an isolated negative inflow test on the downhole liner tops, displace the well to completion fluid, and filter to the required specifications.

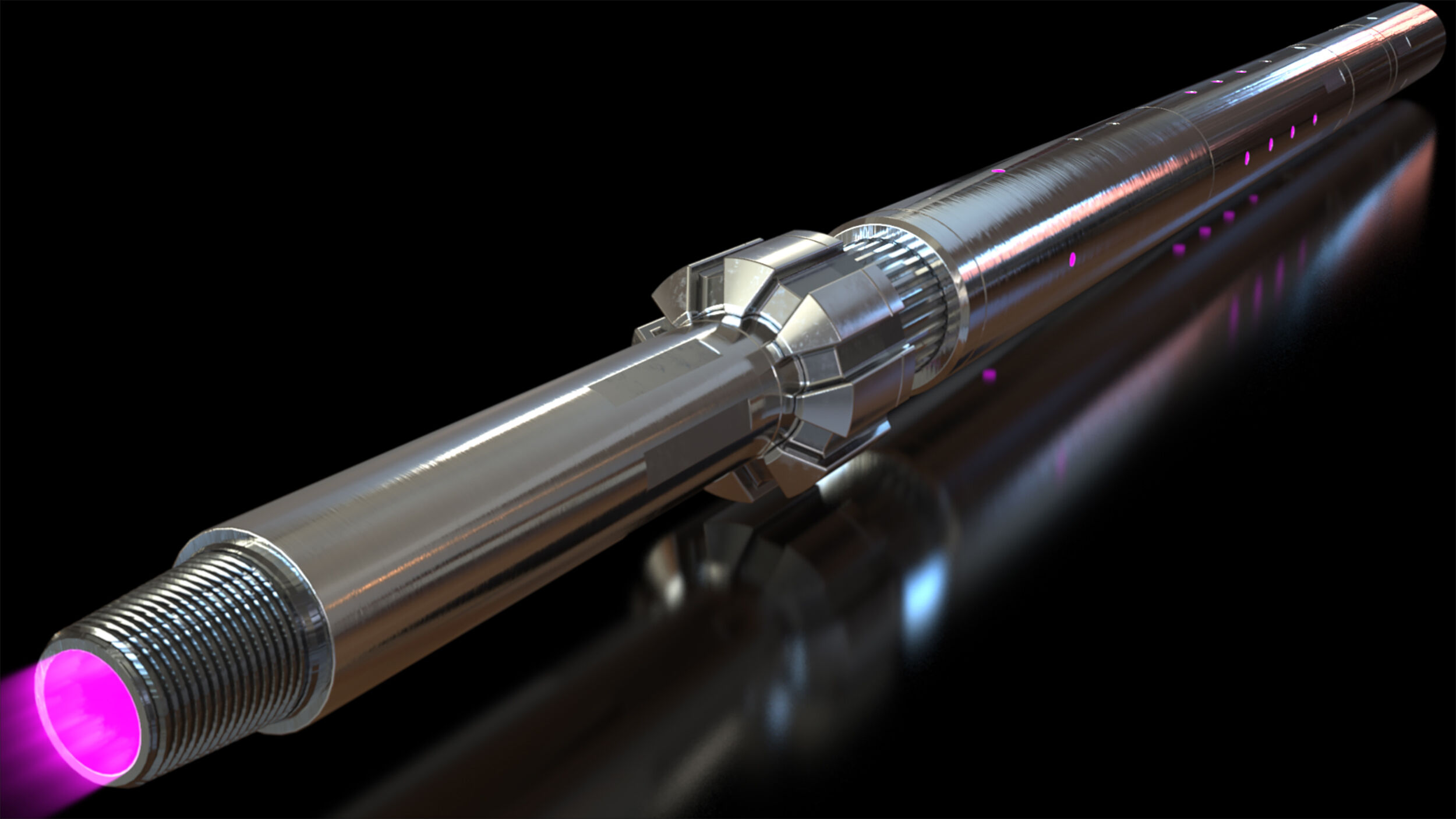

Based on our extensive track record in performing similar operations, the customer selected the Halliburton CleanWell solution. To accomplish the well objectives in a single trip, Halliburton integrated the Turbo Tech® II multi-activation bypass valve and the Inflow Tech® high-performance negative test packer with setting control module (SCM) into the wellbore cleanup string. This approach maximizes the efficiency of two industry-proven compression-set tools, which saves the customer significant time and costs.

trip operation achieved objectives

compression-set tools ran in the same string

customer significant time and money

Prejob planning played a key role in the successful job execution, which involved communications not only between the global and country operations personnel but also with personnel from other locations who performed similar tasks. Drawing upon their experience was helpful in ensuring a safe and successful operation. Additionally, Halliburton mobilized local personnel to Norway to gain vital job planning and shop training ahead of the operations.

Through effective collaboration both internally and with our customer, successfully introduced new technologies, achieved the customer’s well objectives, provided essential training to HCT personnel and utilized existing global assets. Moreover, our team of engineers designed and implemented tailored solutions that met the specific needs of our customer.

Reduce well construction costs with the latest-generation of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and optimized software modeling.