Search

Search

Search

Search

IsoBond™ cement system mitigates shallow saltwater crossflow and provides dependable barrier

Download PDFMature Fields

Increased formation pressure that creates corrosive crossflow

Texas

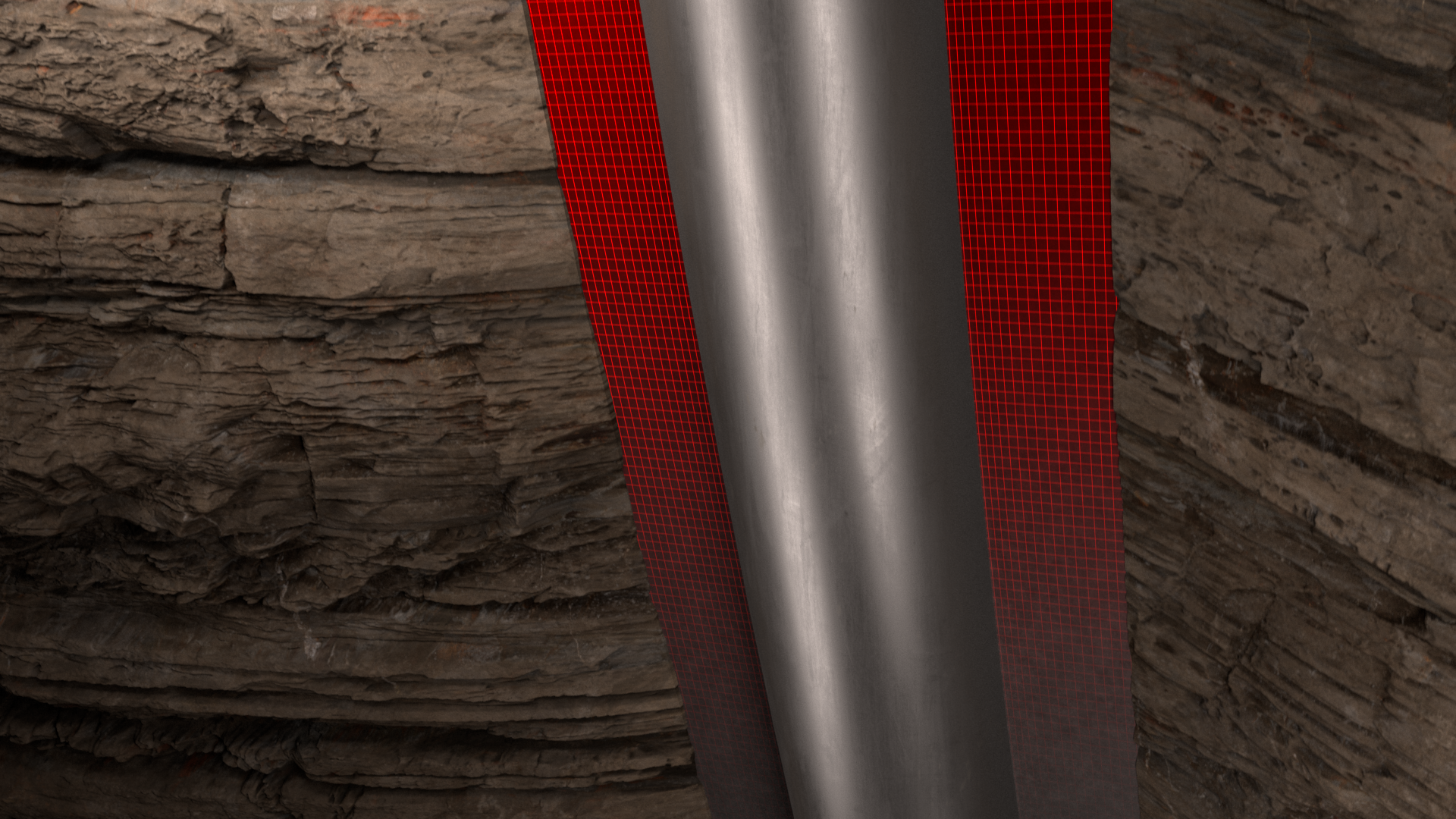

Operators drilling in the northern Delaware Basin face a unique challenge that results from injected saltwater disposals in the upper Delaware Mountain Group (DMG) formations. This injection zone increases formation pressure and creates corrosive crossflow, which causes poor cement coverage and subsequent casing corrosion. As a result, operators face significant remediation costs and production delays during remediation efforts.

During primary cement operations within the DMG formations, crossflow washes out the cement slurry after placement, which leaves casing exposed to the corrosive flows. Even when cement is circulated to the surface during the primary operation, cement bond log (CBL) results confirm there is no cement present behind the casing. Operators have attempted to use higher-density fluids to hydrostatically overbalance the flow zone. However, this was ineffective because the fracture gradient of the lower DMG formations was exceeded, which led to lost circulation and lower than planned top of cement (TOC).

To address the crossflow, Halliburton proposed the IsoBond™ cement system, which provides a short zero-gel time, short transition time, tight fluid-loss control, improved shear bonding to the casing and formation, and reduced permeability of the cement sheath. By shortening the vulnerable cement slurry transition phase when the hydrostatic pressure drops below the formation’s high pore pressure, the IsoBond cement system slurry has already built enough gel strength to resist and prevent fluid influx. Additionally, the slurry incorporates pre-set and post-set expansion additives to help ensure the cement expands to form a permanent seal that isolates the flow zone.

Lost production time

Confirmed isolation

The IsoBond™ cement system was used as a lower-density lead cement (to manage hydrostatic pressure) and placed in the DMG formation and circulated to surface. This solution provided a competent barrier in the flow zone, confirmed by a post-job CBL. This technical solution addressed the crossflow challenges operators face during cement operations in the DMG formations and allowed the operator to reduce remediation costs and prevent lost production.

IsoBond™ cement system mitigates sustained casing pressure by managing gas migration and annular flow.