Search

Search

Search

Search

Cement solution leads to excellent sonic and ultrasonic log results in less than 72 hours

Download PDFMature Fields

Isolate high-permeability, high-pressure sandstone reservoirs

Ecuador

In Ecuador’s Oriente Basin, mature wells often require a single production string to cover all Napo formations. This design exposes high-pressure, high-permeability reservoirs, making zonal isolation critical to prevent crossflow and water production. Satisfactory cement bonding in front of the sandstones is important to prevent water production attributed to the presence of high-pressure aquifers.

The operator required isolation of multiple reservoirs in a single production string, which included a diverse lithology of intercalated sandstone, limestone, and shale formations. The sandstone zones are characterized by high permeability and oil-water contact with active high-pressure aquifers, which often resulted in poor cement bond log (CBL) results and debonding issues. These conditions required a cementing solution capable of managing variable pore pressures and formation characteristics.

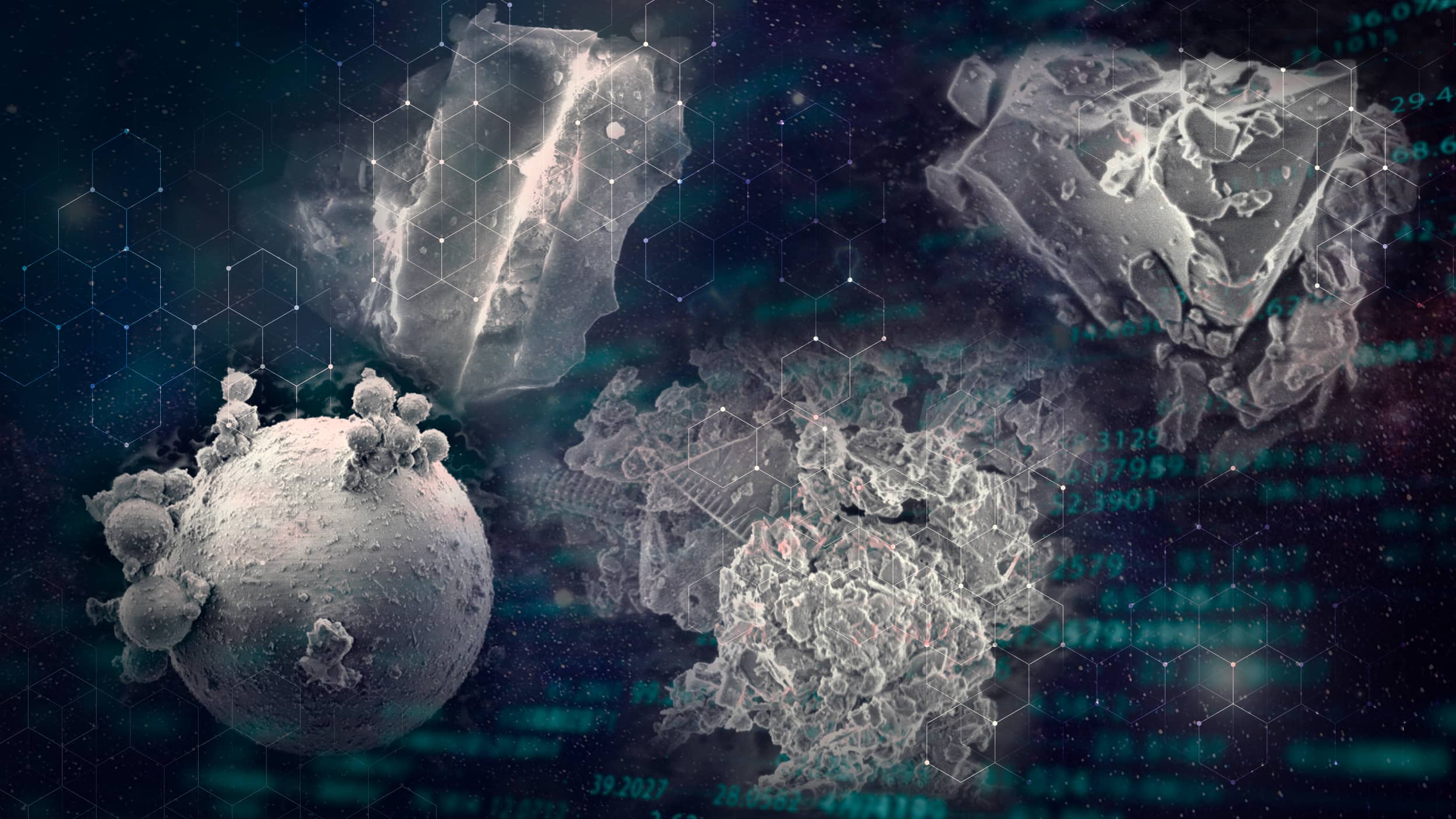

Halliburton designed and deployed a tailored fluid train to condition the wellbore before cementing. The Tuned® Defense™ spacer was selected for its rheological hierarchy and ability to minimize fluid losses in permeable zones. For the cement job, the 14.5-lbm/gal NeoCem™ system was used to manage equivalent circulating density (ECD) and reduce shrinkage associated with conventional Portland cement. This combination provided a dependable barrier across diverse lithologies.

lbm/gal NeoCem system managed ECD

Confirmed isolation in less than 72 hours

Cement bond logs (CBLs) were run after 70 hours of wait-on-cement (WOC) time. Sonic logs showed low amplitude, strong formation arrivals, and no pipe arrivals, which indicated excellent bonding. On the same run, ultrasonic logs confirmed high impedance and uniform cement distribution throughout the cemented interval. The successful deployment of Tuned® Defense™ spacer and NeoCem™ system supported the operator in completing the well with verified zonal isolation.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Reduced Portland content helps customers lower carbon emission baselines and provides engineered systems with enhanced barrier performance.