Search

Search

Search

Search

Deep azimuthal resistivity expands production in a sandstone formation

Download PDFHeavy Oil

Recover heavy oil trapped in soft sand formation

Canada

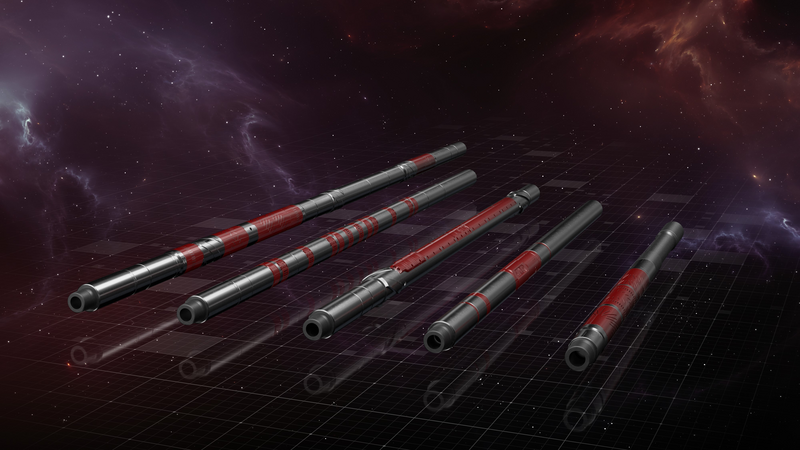

StrataStar™ deep azimuthal resistivity service, featuring:

Steam-assisted gravity drainage (SAGD) production design allows for the recovery of heavy oil trapped in sandstone formations. It requires a pair of horizontal wells with a slight vertical separation. Steam injected from the injector well lowers the bitumen viscosity, so it flows down toward the producer well below.

Vertical permeability is a critical parameter that impacts the effectiveness of the SAGD recovery process. Layered shale lenses and mudstone breccias from past riverbanks occur within the Canadian sandstone formation. However, their location remains unknown until penetrated while drilling the well, and even then, geologists can have difficulty estimating their vertical extension. These natural steam barriers affect bitumen recovery because they prevent the chamber from developing around the wells, leading to a lower return on investment.

sampling rate

ft per hour ROP

ft horizontal section

The Halliburton Sperry Drilling StrataStar™ deep azimuthal resistivity service was recommended for this application as a field trial of the new service. This innovative technology uses an oriented electromagnetic propagation signal to measure the resistivity up to 30 feet (±9 meters) all around the borehole while drilling. Combined with advanced inversion processing, it delivers a high-resolution resistivity map, revealing structural features and fluid distribution along the well to drive optimal well placement.

The StrataStar service was implemented in a pair of horizontal injector-producer wells to verify the resistivity mapping accuracy. The 2,300-foot-long (701-meter-long) producer was drilled first, followed by the injector three weeks later. The high-resolution mapping service was run while drilling both wells, with its fastest sampling rate of 16 seconds to accommodate the 500 foot/hour (152 meters/hour) average rate of penetration (ROP). The two StrataStar datasets were processed independently, revealing the high and low resistivity zones at 16.5 to 19.7 feet (5 to 6 meters) above and below each well.

iStar™ Drilling and Logging Platform

Multilayer mapping for precise well placement

Download Data Sheet

Deep azimuthal resistivity measurements for multilayer mapping and precise well placement.

Ultra-deep resistivity service mapping reservoir and fluid boundaries up to 225 feet from the wellbore.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere