Search

Search

Search

Search

Cloud-based application for designing and assessing electric submersible pump performance

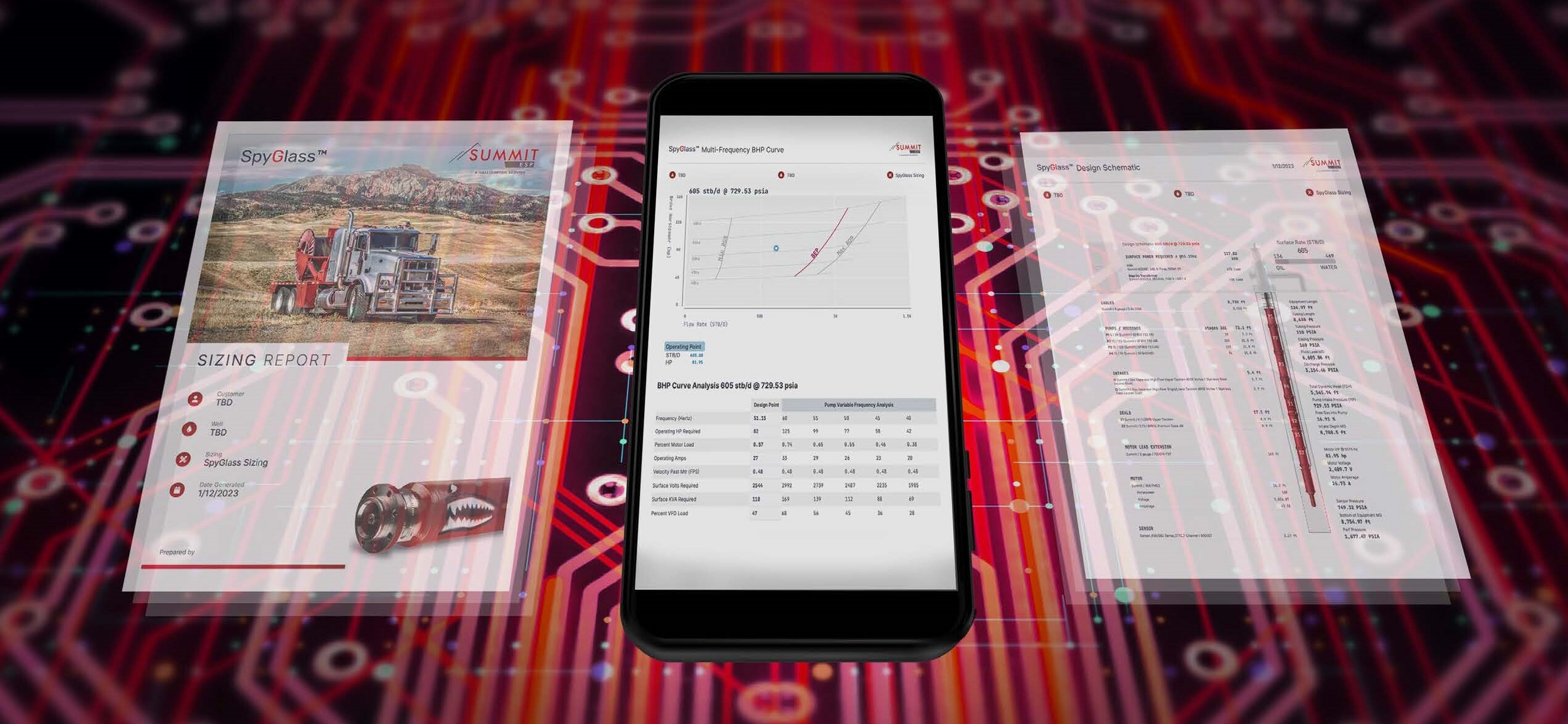

Download PDFSpyGlass ESP pump-sizing software is a cloud-based, cross-platform web application with online and offline capabilities streamlining and integrating several data sources, transforming trust-worthy insights into long-term ESP success.

"The multi-case scenario comparisons make it easy to make the best choice for equipment selection. We realized a huge cost savings. SpyGlass has been a game-changer for us."

Whether on a PC, tablet, or mobile device, you can design and troubleshoot your pumping system with almost 100 custom-built alerts to guide you in the equipment selection process.

Customizable layouts further enhance design capabilities with embedded graphs and equipment-specific calculations.

Once in production, we take a holistic approach to system analysis, offering comprehensive performance evaluations so you can quickly assess your ESP operating health.

The entire dedicated Summit ESP team, including engineers and monitoring personnel, is available every step of the way, from the design and build phase to reporting and performance evaluations, to help you maximize your production.

Cloud-based application for designing and assessing electric submersible pump performance.