Search

Search

Search

Search

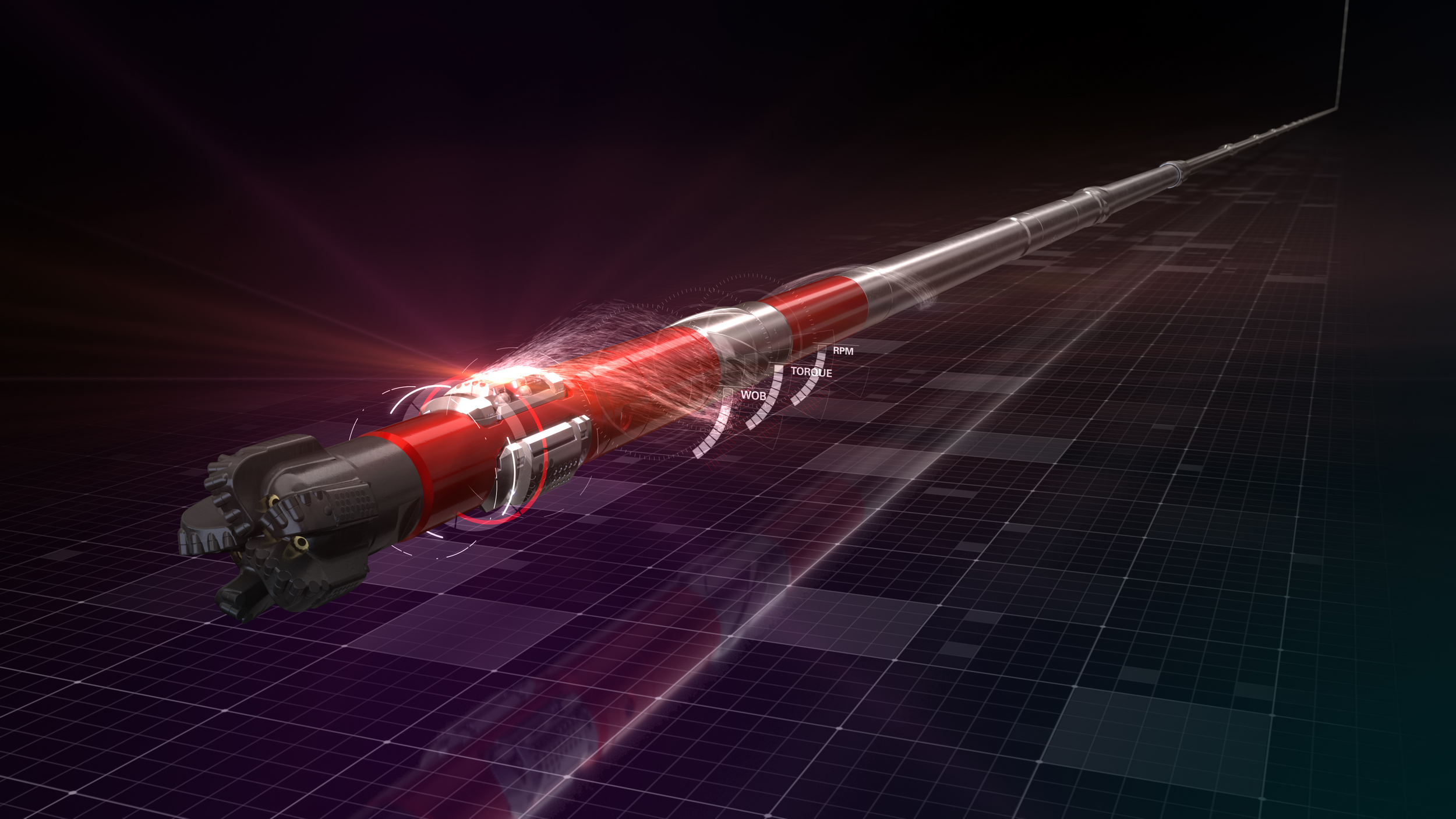

4.75-in. iCruise® X intelligent rotary steerable system drills 4,734-m lateral in a single run

Download PDFUnconventionals

Drill extended lateral sections in the Montney play under harsh conditions

Canada

Drill extended lateral sections in the Montney play more than 4,734-m long under harsh conditions:

A major operator in northeast British Columbia Montney formation, a shale gas and tight oil resource, is pushing the drilling envelope by consistently extending lateral lengths of more than 4000 m to increase reservoir contact and production rates from a single wellbore. The operator engaged Halliburton Sperry Drilling with the challenge to drill a 4,734-m lateral section in a single run. Using the iCruise X intelligent rotary steerable system (RSS) in this harsh drilling environment increased the drain section while improving efficiency and reducing well delivery time, setting a record for lateral length and ROP, reaching TD 2.5 days early in the last well.

The Montney formation is known to present severe vibration challenges when attempting to achieve the rate of penetration (ROP) required for cost-efficient drilling operations. Axial and high-frequency torsional vibrations are among the primary obstacles to sustaining the consistent tool face control needed to maintain steerability and prevent tool failure.

To allow for a swift casing run and successful completions, tortuosity must be minimized, despite the continuous target changes necessary while drilling the lateral as the geosteering model is updated. Hence, the drilling system used must be capable of delivering precise, yet smooth wellbore placement achieved by the desired inclination and true vertical depth (TVD) targets.

Days ahead of schedule

meters in a single run

Run efficiency

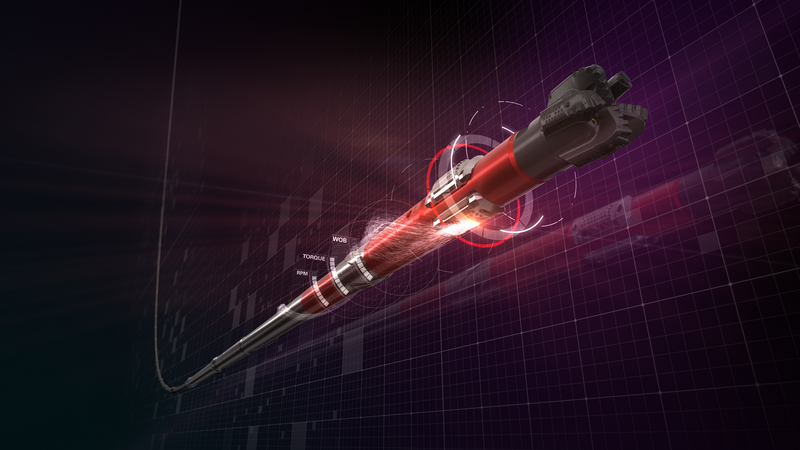

The Halliburton team proposed a 4.75-in. iCruise X intelligent rotary steerable system (RSS) to successfully achieve this lateral length in one run with competitive ROP. With six downhole processors and 1,000 toolface updates per second, the iCruise X RSS provided an actuation system capable of supporting steerability—even in the presence of severe axial vibration and stick-slip. Furthermore, in collaboration with a Halliburton global support team, the steering head was redesigned to accommodate more demanding surface parameters and minimize the cost of repairs after drilling record lateral lengths. The iCruise X motor-assisted rotary steerable system (MARSS) delivered the optimum horsepower required to drive the BHA and maximize the ROP. Furthermore, the DrillingXpert™ well engineering software was used for BHA design modeling to meet the steering objectives while balancing side forces across the BHA and identifying the optimum operating window to minimize vibration. The ADT® Drillstring Integrity and Hydraulics management services delivered real-time drilling performance optimization and vibration mitigation.

The operator successfully drilled four wells in the Montney formation that were each more than 3,500-m with zero non-productive time (NPT). In the last well of this drilling campaign, the operator broke its previous record for lateral length and ROP in the Montney, achieving TD 2.5 days ahead of schedule. The enhanced control from iCruise X RSS and CruiseControl technology allowed delivery of minimal tortuosity laterals in the presence of severe vibration. This led to additional time savings in casing runs. Over the course of drilling these wells, the steering head design was improved to reduce the cost of repairs to zero while sustaining 100% run efficiency.

Automation-enabled platform designed specifically for longer well applications in harsh environments.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.