Search

Search

Search

Search

BHKA™ plug setting disconnect tool allows operator to permanently abandon 1015-m openhole section in single trip

Download PDFUnconventionals

Place abandonment cement plug in 1015-m openhole section

Argentina

Cement plugs are required for proper isolation in plug and abandonment (P&A) operations. The conventional method to stack short-length cement plugs usually requires a long cement setting time and has a low success rate related to high contamination levels.

As part of the permanent abandonment plan, an operator in Argentina required isolation of 1,015 m of a 6.131-in. openhole section and a minimum of 30 m of coverage inside the cemented 7-in. casing. Previous conventional cement plug operations indicated a minimum of three independently positioned/stacked cement plugs were necessary to achieve the required isolation from the bottom of the hole at 3,890 m with effective TOC at 2,800 m. An additional surface cement plug would position the string with its base at 860 m and effective top of cement at 660 m.

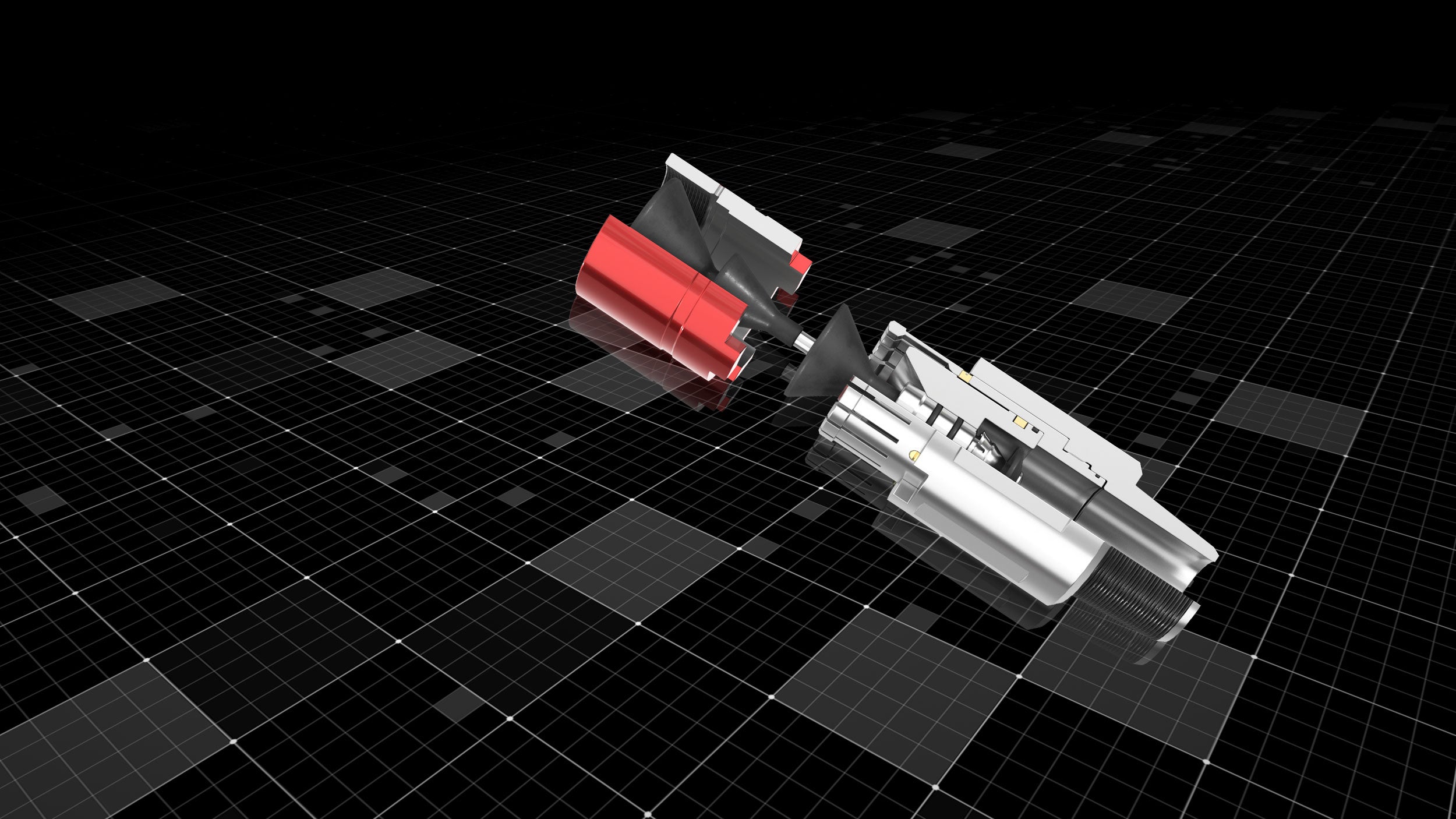

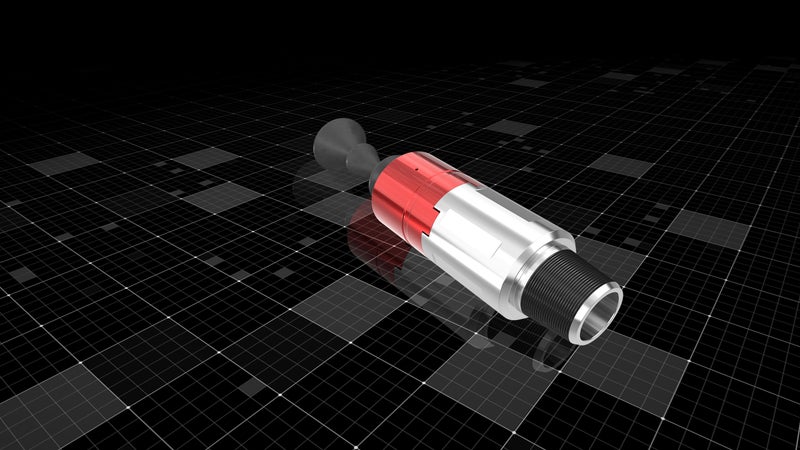

Halliburton proposed the deployment of the BHKA™ plug setting disconnect tool with a sacrificial tailpipe to enable the safe placement of a single, undisturbed, 1,090-m cement plug. The displacement dart and BHKA tool’s safe disconnection mechanism help drastically minimize cement contamination and the risk of a stuck string associated with spotting the ~1,000-m long balanced cement plug.

A wirelessly operated Commander™ 500 top drive cement head was also proposed to promote safe and positive dart displacement, maintain effective mechanical fluid separation during cement plug placement, and support string rotation best practices for optimal cement plug placement. Halliburton designed a 16-lbm/gal slurry, following best practices and considering the best scenario to achieve the operator’s abandonment objectives.

Cement plug placed in single trip

Tagged 5-m above planned depth

Hours rig time saved

After reaching bottom at 3,890 m with 3 1/2-in. tubing, the cement operation followed the design of service, including wellbore circulation and full string rotation at 10 rev/min, in preparation for spotting the cement plug. At the end of cement displacement, a clear tailpipe release was observed by the 1,900-psi differential pressure spike. Once the setting time was complete, TOC was tagged 5 m above plan, which met job objectives and allowed placement of the 200-m surface-balanced plug with the same work string.

The streamlined operation eliminated the need for stacked cement plugs, additional rig time, and well cleanup operations—costs that would have been incurred by the three independent cementing operations using conventional methods. This solution saved an estimated 20 hours of rig time.

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.