Search

Search

Search

Search

Geomechanics modeling, nonaqueous fluid (NAF), and sealant combine to contribute to wellbore stability, breakout mitigation, and successful completion of well

Download PDFUnconventionals

Improve wellbore stability, reduce days on well

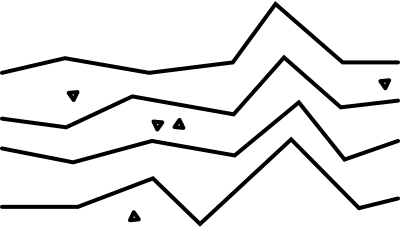

Marcellus/Utica Shale

A drilling operator in West Virginia collaborated with Halliburton to manage a wellbore instability challenge. During operations, the operator and Halliburton noted an 80% increase in large cuttings. Halliburton personnel worked with the operator to gather, analyze, model, and implement a solution that reduced the cuttings size and improved wellbore stability. Halliburton implemented BaraXcel® clay-free, synthetic-based nonaqueous fluid (NAF), and BaraSeal™-957 wellbore sealant to help stabilize the wellbore.

No additional washout occurred, and instability signs were reduced by 50% on the subsequent well drilled with the same profile in the same formation.

Initial instability during the first well posed new wellbore risks and added significant time due to reaming, tripping, and running casing. Wellbore instability poses several operational risks, such as pack-offs, lost returns, and pressure spikes. If untreated, propagation can occur with an increased risk of worsening wellbore conditions that can lead to plug and abandonment.

The optimal way to deal with wellbore instability is to seal the microfractures in the well prior to propagation and mitigate the need for remedial actions with the risks associated above.

Pressure management becomes key in situations where instability occurs. The bedding plane gets weaker the more the shale sees pressure fluctuations. This increases wellbore instability, identified by larger cuttings and cavings showing up on the surface. As larger cuttings fall into the wellbore, it enlarges, making it more difficult to achieve flow rates that clean the hole.

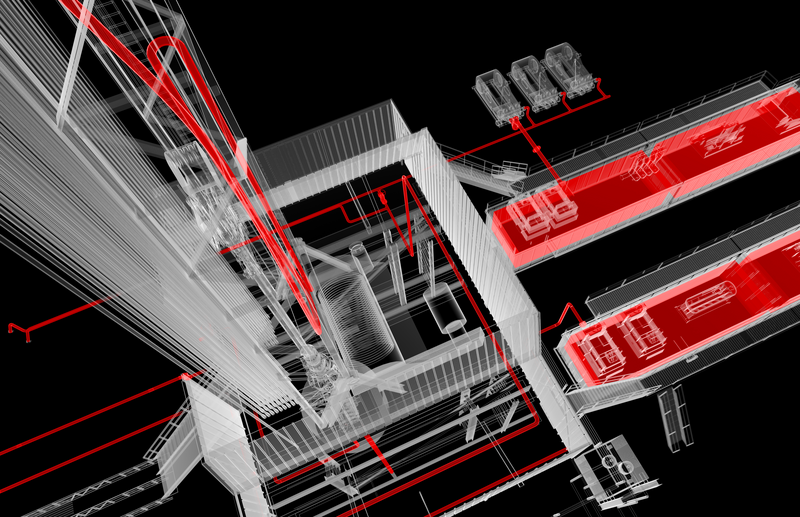

Halliburton took a multifaceted approach to this challenge. First, DFG™ geomechanics modeling allowed Halliburton to predict the integrity of the formation and tailor the solution. Second, the BaraXcel® clay-free non-aqueous fluid technology reduced pressure spikes due to its polymeric nature. Third, BaraSeal™-957 nanotechnology wellbore sealant was incorporated to seal the microfractures in the formation.

After seeing signs of instability on the first well, Halliburton and the operator used a background treatment of BaraSeal™-957 to help prevent further wellbore destabilization. Low-impact drilling practices were recommended to reduce the impact on near-wellbore formations. Halliburton and the operator conducted daily DFG™ simulations to predict and help manage hole cleaning efficiency along with pressure management to limit formation exposure to any unnecessary equivalent circulating density increases (ECDs). Coordination with the Baroid Separation Solutions (BSS) team for low-gravity solids mitigation and rheology management was also crucial to the operation’s success.

Days saved on second lateral with nano sealant

Reduction in drilling time well on well

Quicker casing run time

Less time spent tripping out of the hole

After applying BaraSeal™-957 wellbore sealant to the BaraXcel® NAF system, no additional washout occurred on the first well, helping to prevent further wellbore destabilization. Hours spent drilling the second well were reduced by 41%, time spent tripping out of the hole was reduced by 42%, and the casing run was improved by 38%. The operator completed the second lateral 2.9 days faster than the initial well.

Discover how this clay-free, non-aqueous fluid system can help you upgrade drilling performance.

Expansive portfolio of engineered high-performance water-based fluids and additives that can be customized to meet your specific challenges