Search

Search

Search

Search

Unconventionals

Provide a CRI methodology for optimizing cuttings and waste disposal

Ecuador

The waste management solution initially used by an operator in Ecuador included cuttings storage pits that presented challenges due to space limitations and potential risk to the environment.

The operator also wanted to reduce its dependency on dewatering, along with its need for water and chemical storage at the location.

Baroid personnel recommended its BaraCRI™ cuttings reinjection (CRI) methodology. CRI provides a permanent and contained zero-discharge solution for drill cuttings and other operational waste related to solids and fluids. The waste streams are normally injected as slurries or mud batches into induced fractures created by the injection process in the selected injection zone. This solution delivered several benefits, including:

The CRI method allowed the customer to eliminate cuttings pits. Additionally, all waste fluids (dewatering water, contaminated rainwater in cuttings pits, and rig wash) were used to prepare the injection slurry. This also reduced chemical usage for the dewatering process.

For one directional well and three horizontal wells, a total of 91,728 bbl of fluids (slurry + rinse) were disposed of by using the CRI process, whereas the use of pits would have resulted in approximately 15,000 bbl of surface disposal per well.

Nonproductive time (NPT)

bbl of fluids disposed for 4 wells

bbl injected in a second campaign for 7 wells

In this first CRI project in Ecuador, the application was used throughout the drilling process. Drilled cuttings and drilling waste were processed daily.

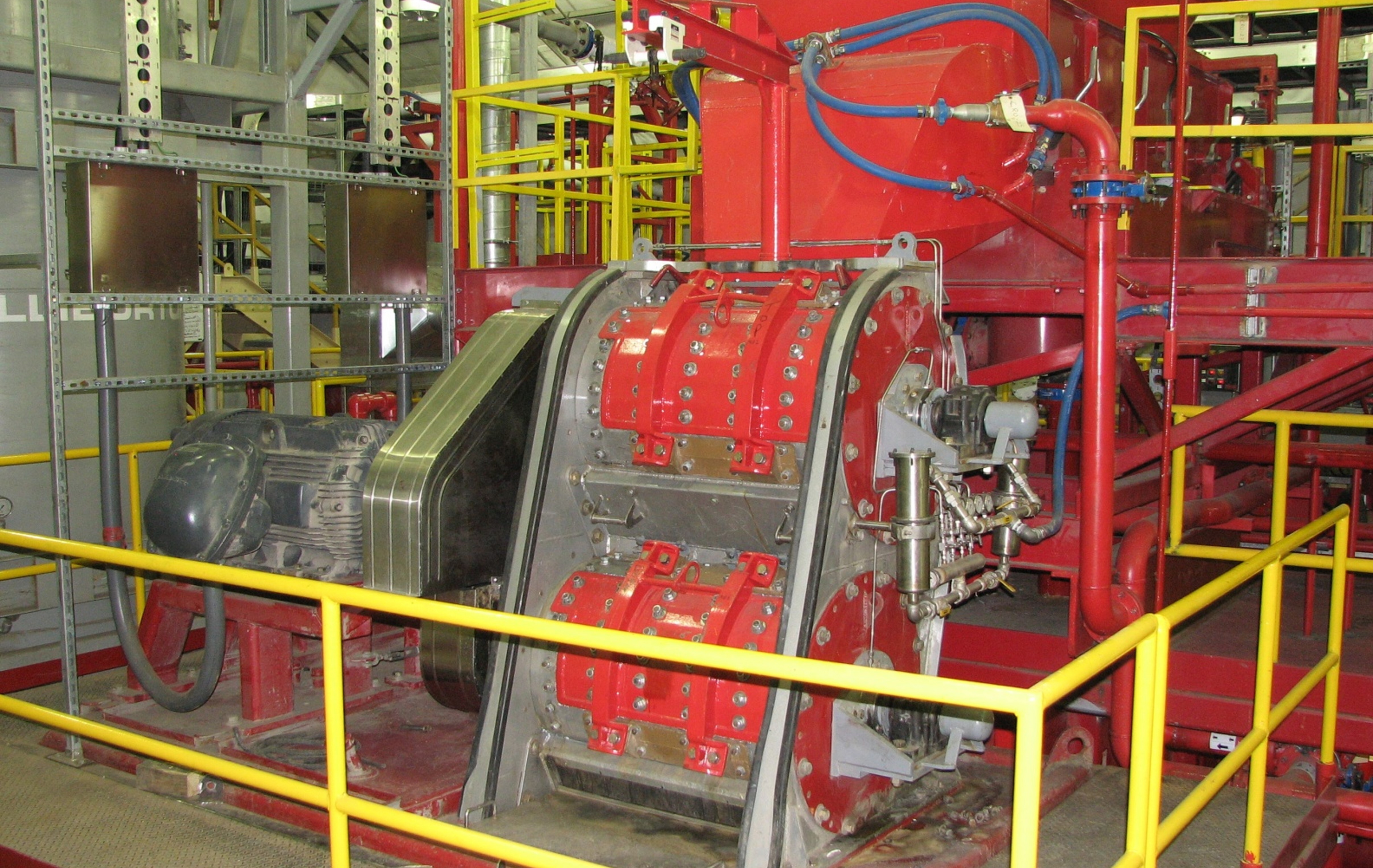

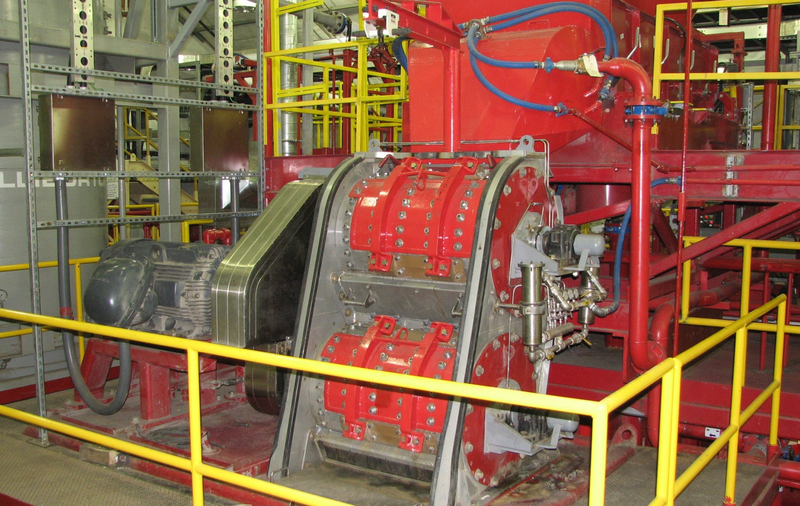

The customized BaraCRI system for this specific project included a combined grinding system with hammermill and centrifugal grinding pumps. Solids were processed through 100-hp grinding pumps with a tungsten-carbide impeller based on the lithology.

The slurry met all specified properties as determined in the feasibility study. The reinjection parameters (1.14–1.38 SG, surface pressure below 2,500 psi, and an injection rate of 3–5 bbl/min) used during the operation also remained within the feasibility study parameters.

The premier CRI application in this environmentally sensitive and remote area proved successful. This project was carried out according to the plan and in compliance with all health, safety, and environmental (HSE) and service quality requirements. More than 90,000 bbl was injected downhole, with zero nonproductive time (NPT). By improving waste management logistics and bioremediation processes, operational costs were optimized. Based on the success of this first CRI application, the customer elected to use BaraCRI services on its second campaign of seven wells, where a total volume of 165,085 bbl was injected.

We combine two-stage hammermill processing with advanced slurry rheology design to optimize downhole injection of cuttings.

Comprehensive and efficient technology solutions for optimal fluid recovery and minimal environmental impact.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.