Search

Search

Search

Search

Reliable new design for motor lead extensions (MLE)

Download PDFMature Fields

Decrease pothead electrical and MLE failures in high-temperature, gassy wells

North Dakota

Multiple electric submersible pump (ESP) customers reported pothead electrical failure in high-temperature, gassy wells. These failures often trace back to the motor lead extension (MLE), which acts as both the electrical connector and seal to the motor, shortening pump run life.

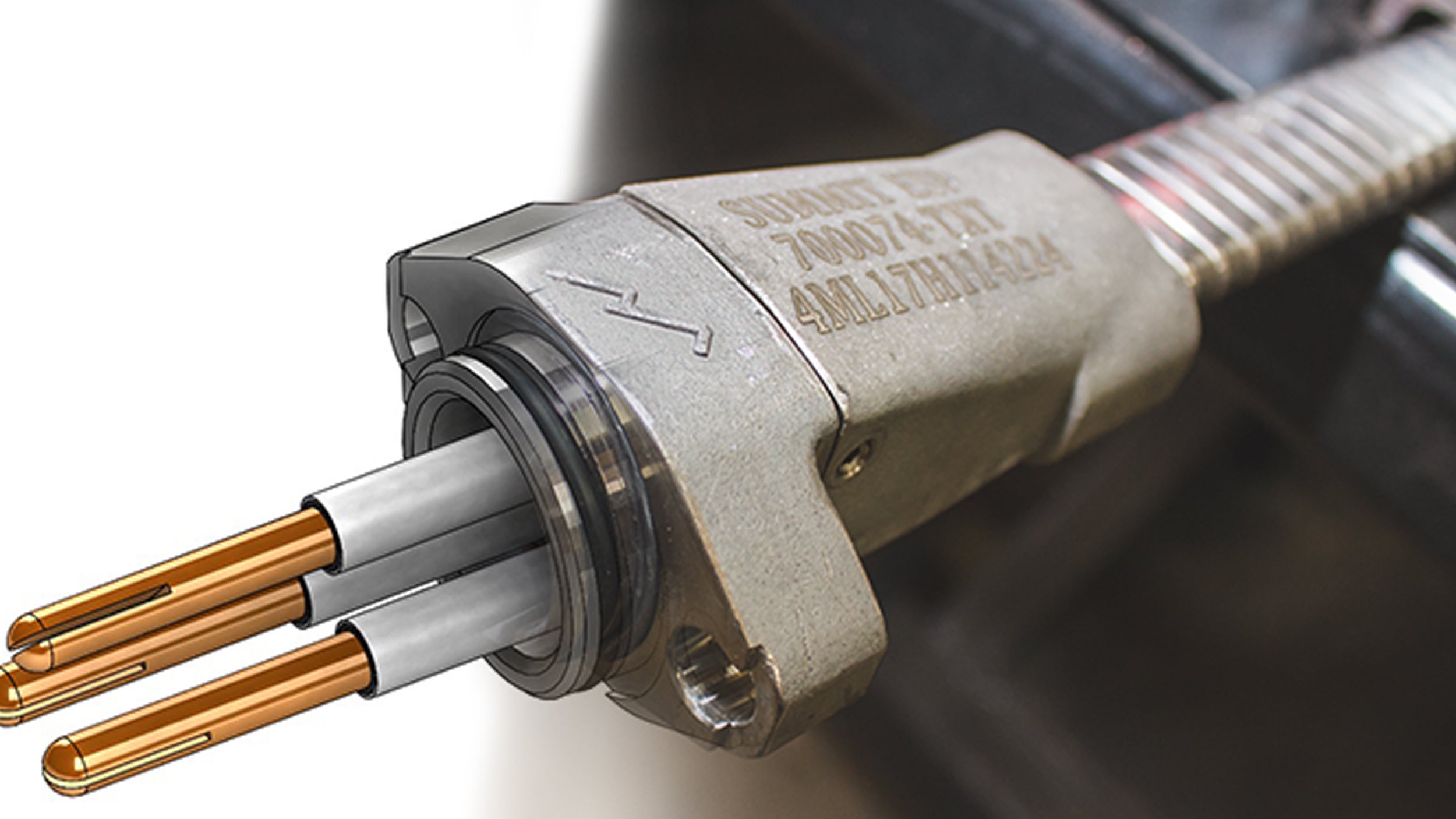

Summit ESP® Avenger® MLE for increased reliability in high-temperature, highly corrosive gassy wells. The patented design within the Avenger MLE has a low profile, flat cable pigtail design that is spliced to the lower end of the main power cable. The design reduces rubber in the seal by 90 percent and uses an O-ring within the motor head to protect the seal. Its tape-in connection creates a 260 percent longer arc path than typical in the industry.

The Avenger MLE improvement over the conventional design delivers electrical system protection in thermal ratings >400°F (204°C) BHT. This new design helps reduce gas impregnation and thermal expansion from high wellbore temperatures and heat generated by the motor head, dramatically decreasing cable insulation shear and motor failure.

In partnership with customers, Summit ESP defined a series of accelerated life test protocols (ALTP) to compare Avenger MLE performance against two competitors. The seven-day test included field testing as well as simulated wellbore conditions using a pressure vessel at 4,000 psi (generated by carbon dioxide and nitrogen), a mixture of water and diesel to simulate wellbore fluids, and temperature cycled to 500°F.

Testing revealed two fatal flaws in the competitor MLEs related to the internal rubber seal. These flaws—thermal expansion and gas impregnation—caused swelling that resulted in electrical failure. The Avenger MLE did not suffer these flaws and was still fully functional at the end of testing.