Search

Search

Search

Search

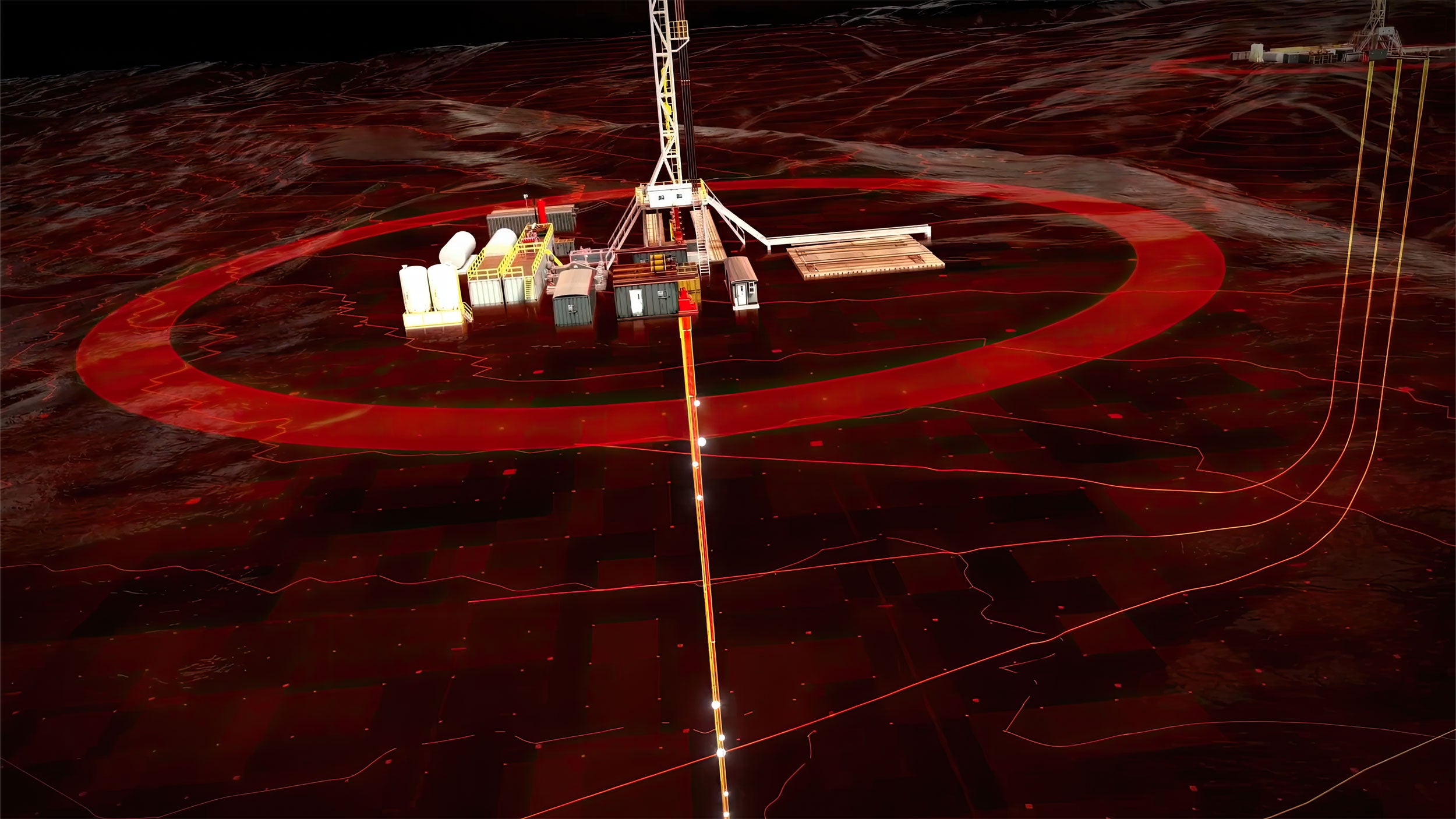

LOGIX™ automation and remote operations and iCruise® intelligent RSS system deliver record performance and reduce personnel at the rigsite

Download PDFDeepwater

Complex geology and salt stringers causing vibration in deepwater drilling

Brazil

Traditional drilling operations rely on manual intervention that can be time-consuming, costly, and pose safety risks. However, autonomous drilling systems are now available to help improve efficiency and safety. The advantages of automated remote drilling techniques were explored in Brazilian presalt reserves to increase efficiency, reduce operational costs, improve safety, and minimize environmental impact.

Brazilian presalt reservoirs have deepwater zones that present challenges to drilling because of complex geological formations and extreme conditions. Traditional drilling methods require substantial manual intervention and multiple personnel in hazardous environments. Because of the extended length of these well types, fatigue and continuous crew changes can lead to nonproductive time (NPT).

The most effective method for accident prevention is to reduce personnel on the rigsite to minimize exposure to the risks associated with offshore operations.

The LOGIX™ automation and remote operations platform was deployed at the offshore rigsite. It was operated by directional drillers from the operator’s remote drilling center. The LOGIX™ platform and iCruise® intelligent RSS controlled surface and downhole automation and performed directional drilling commands without human intervention.

Automated drilling systems continuously operate without crew shift changes or breaks to ensure a consistent drilling pace. This reduces downtime attributed to fatigue or human error. The use of advanced algorithms and artificial intelligence enables real-time surveillance and decision-making to optimize drilling performance and reduce NPT. This improved efficiency translates to cost savings because less time is required to complete drilling projects.

Drilling in deepwater environments includes inherent safety risks. Automated and remote drilling systems reduce human exposure to hazardous conditions to help protect workers. In addition, real-time surveillance and predictive maintenance algorithms enable early detection of potential equipment failure, prevent incidents, and reduce risks associated with downtime.

Automated drilling technologies that include advanced data analytics and machine learning algorithms contribute to more accurate well placement. Accurate directional drilling delivers a low tortuosity path to reduce torque demand in the following sections. This increases the drilling rate and reduces stress on equipment.

Embedded in a remote center located in the operator’s office, Halliburton personnel can attain a level of proximity that fosters seamless collaboration and information exchange. This connection allows real-time communication with customers to enable rapid decision-making about drilling operations.

The adoption of automated remote drilling techniques in the Brazilian presalt environment offered numerous advantages. Key benefits included increased efficiency, reduced operational costs, improved safety, and minimized environmental impact. LOGIX™ automated trajectory control and improved wellbore tortuosity, and ROP across multiple projects in this environment.

Further research and development of automated drilling technology continues to enhance the efficiency and effectiveness of presalt drilling operations to help with the sustainable exploration of this valuable resource.

Remote operation decreases the need for onboard personnel because it allows operators to monitor and manage multiple tasks. The remote center established by Halliburton in the operator’s office has improved communication and collaboration processes. The accessibility among all parties, combined with the efficient exchange of lessons learned, has accelerated drilling decisions and strengthened collaborative efforts.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.