Search

Search

Search

Search

Pumps operating at best efficiency across multi-well systems continuously for 18 months

Download PDFHigh volume of produced water from core assets

Permian Basin

A major operator in the Permian Basin is on a mission to be a leading and low-cost operator. Water management is a key part of that strategy, including treatment, recycling and disposal. Halliburton collaborated with this customer in the design of a sophisticated disposal system that automatically manages flow rate and pressure for a series of saltwater disposal wells to ensure peak efficiency and permit compliance, with the system operating unmanned.

Wells in the Permian Basin have a high water-to-oil ratio, making produced water management a necessity. Operators compete for resources for treatment, transportation, and disposal. The customers’ strategy focuses on the Permian Basin, making it vital that operations be low risk and cost-controlled. The customer sought and received permits for multiple disposal wells and built an infrastructure of piping and storage to move saltwater from production wells to the disposal areas.

For optimum performance, they needed an automated pumping system that could deliver the optimal volume for system equilibrium at a pressure compliant with permits.

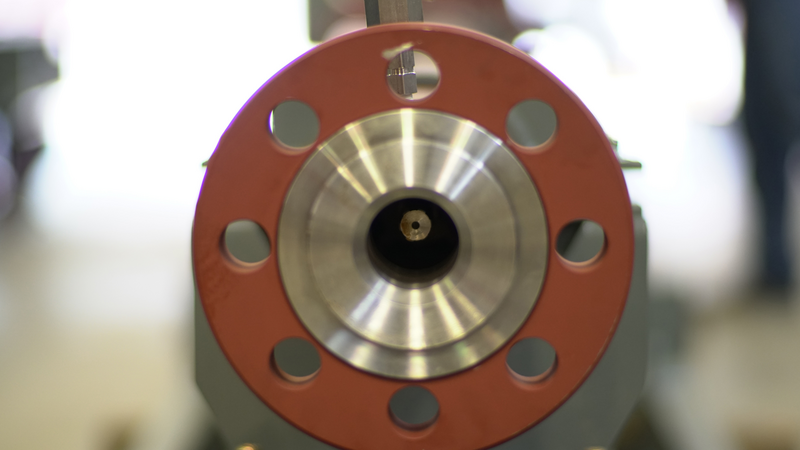

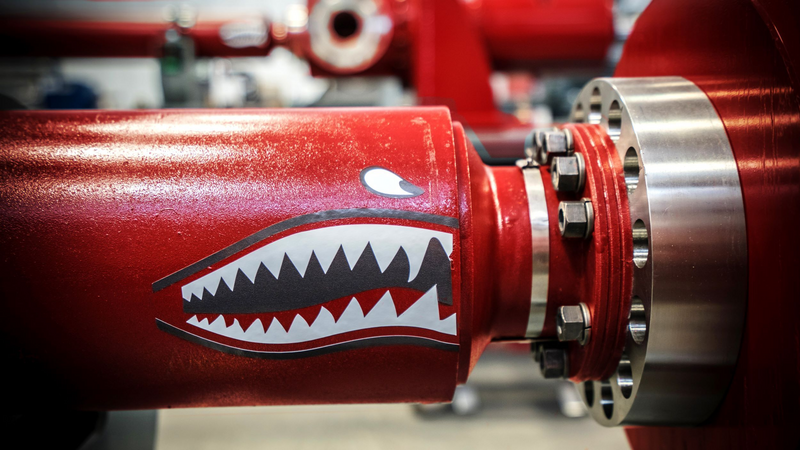

Summit ESP® – a Halliburton service proposed and delivered horizontal pumping systems (HPS) combined in two stages to ensure full capacity for each injection well and operating at 50,000 BWPD @ 5,000 psi. Multiple pumps in each stage work in a parallel to series to parallel orientation to move needed volume and increase pressure, and multiple stages enable the system to reach full permitted pressure. Programmable automation controllers (PACs) are integrated into the overall system to efficiently move produced water to disposal.

Each pumping system design met unique requirements including piping distances and the retrofit of existing pumps. The overall system currently includes three saltwater wells, with a fourth in process, each of which has a tank battery, piping and associated pumping equipment. The system of wells is interconnected and automated, ensuring peak efficiency in moving produced water to disposal. The automation system regulates flow to each facility so that injection does not exceed permitted limits, tanks are not depleted, and pumps do not operate off of best-efficiency.

The real-time automation system is fine-tuned to ensure best efficiency for every individual pump and the overall system. All variable speed drives and control valves are governed by the automation system using feedback from level, pressure and flow transmitters throughout the system. Unique live affinity law calculations, combined with self-learning stage-balancing algorithms in the controller, keep the overall system at peak efficiency as the pump efficiencies, production volumes, and injection pressures fluctuate. The control system is designed such that operator intervention is kept to a minimum.

The system is capable of automatically starting-and stopping based on production demand, removing a pump from service if its counterpart in another stage shuts down unexpectedly, and bypassing the entire second stage if additional injection pressure is unnecessary.

months of continuous pump run time

BWPD (Barrels of Water Per Day)

below the cost of trucking or selling produced water

All automation calculations are performed in real time by measuring and responding to inputs from all pumps, drives, meters, sensors and tank level radar. The automation system and pump configuration has been running for 18 months. LOE are substantially below estimated costs of trucking or selling produced water.

Hercules™ horizontal pumping systems (HPS) are an alternative to positive displacement, split-case, and other surface pumping options.

Pump more efficiently with a focus on lower maintenance costs, longer operational life, and 24/7 monitoring

Halliburton's superior performance and consistent delivery reduces time and maximizes efficiency.